Description

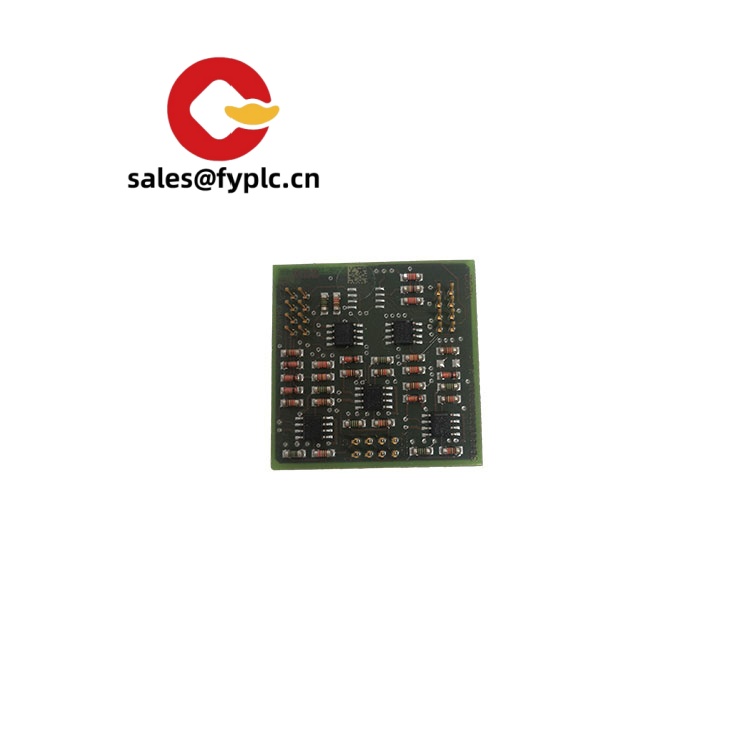

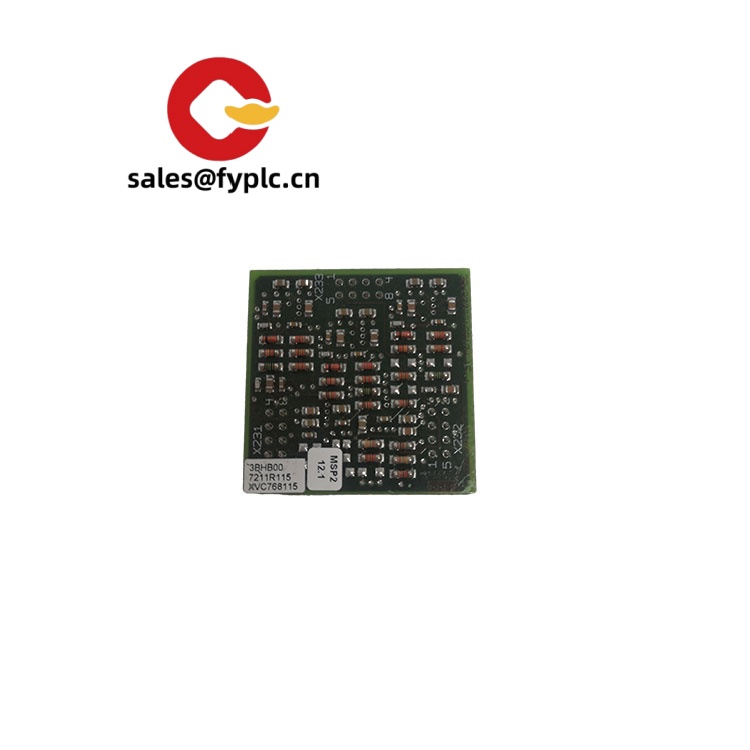

ABB XVC768115-3BHB7211R115 – Drive Control/Gate Interface Board for ABB Industrial Drives

The ABB XVC768115 (ordering code 3BHB7211R115) is a factory-grade control/gate interface board used in ABB drive systems to manage power stage control and feedback. From my experience, this board typically bridges main control logic and the power semiconductor section, providing galvanic isolation, fiber-optic signaling (where applicable), and robust diagnostics. If you’re maintaining ABB drives in continuous process lines, this is one of those spares that gets a line back up quickly without touching the power stack.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in‑stock items; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- OEM spare for ABB drives: The XVC768115 (3BHB7211R115) is supplied to match ABB drive architectures, minimizing compatibility risk during maintenance.

- Isolated control and feedback: Typically uses optically isolated paths to the power section, reducing noise coupling and improving reliability in high-EMI cabinets.

- Fiber‑optic signaling support: Many installations use fiber links for gate/feedback communication, which helps with signal integrity over distance.

- Service-friendly design: Connectorized layout and board mounting that allows rapid changeout during planned or corrective maintenance.

- Conformal coating (in many cases): Helps resist dust and humidity in industrial environments, though exact coating level can vary by revision.

- Status and diagnostics: You might notice on-board indicators and test points that speed up commissioning and fault tracing.

Technical Specifications

Note: Exact interfaces and firmware dependencies can vary by drive family and revision. It appears that validation against your drive type and build list is the safest route before dispatch.

Application Fields

- Process drives in steel, cement, pulp & paper, mining, and oil & gas where fast board swaps cut downtime.

- Converters and inverter sections requiring fiber‑optic gate control and isolated feedback paths.

- Retrofit and lifecycle service of installed ABB drive systems in MCCs and multi‑cabinet drive rooms.

- Test benches and OEM equipment that rely on ABB drive platforms with modular control boards.

Advantages & Value

- Reduced downtime: Drop‑in replacement design means technicians can swap the board and re‑commission in a short window.

- Compatibility peace of mind: Genuine ABB part number (3BHB7211R115) aligns with BOMs used in the field.

- Improved signal integrity: Fiber and optical isolation, in many cases, help stabilize control under heavy electrical noise.

- Cost control: Restores drive functionality without replacing the entire power section or cabinet hardware.

- Technical backing: From my experience, access to ABB documentation and diagnostics shortens fault‑finding on site.

Installation & Maintenance Tips

- Environment: Install inside an IP‑rated drive cabinet with proper ventilation; avoid condensation and conductive dust.

- Power‑down safety: Isolate supply and allow DC link capacitors to fully discharge before touching the board.

- ESD handling: Use a grounded wrist strap and ESD mat; the board’s components are sensitive to static.

- Wiring & connectors: Verify keyed connectors, gently seat fiber‑optic leads, and follow torque specs for any terminal screws.

- Firmware/config: Match firmware or parameters as required by your drive revision; back up settings before replacement.

- Routine checks: Inspect for contamination, clean with approved methods, and confirm indicator LEDs show healthy status after start‑up.

A maintenance lead from a paper mill mentioned they replaced an XVC768115 during a planned stop; the drive came up clean on self‑diagnostics, saving them a day of troubleshooting across the power stage. That sounds typical when the control side is at fault.

Quality & Certifications

- Manufactured under ABB’s quality system (commonly ISO 9001‑compliant production).

- RoHS compliance is typical for current revisions; system‑level CE/UL compliance applies at the drive assembly level.

- Supplied with a 365‑day warranty through our sales channel.

Procurement Note

To ensure the ABB XVC768115 – 3BHB7211R115 is a drop‑in for your system, share the drive type code, cabinet frame, and current board revision. We’ll cross‑check compatibility and ship via FedEx/UPS/DHL on your preference.

Reviews

There are no reviews yet.