Description

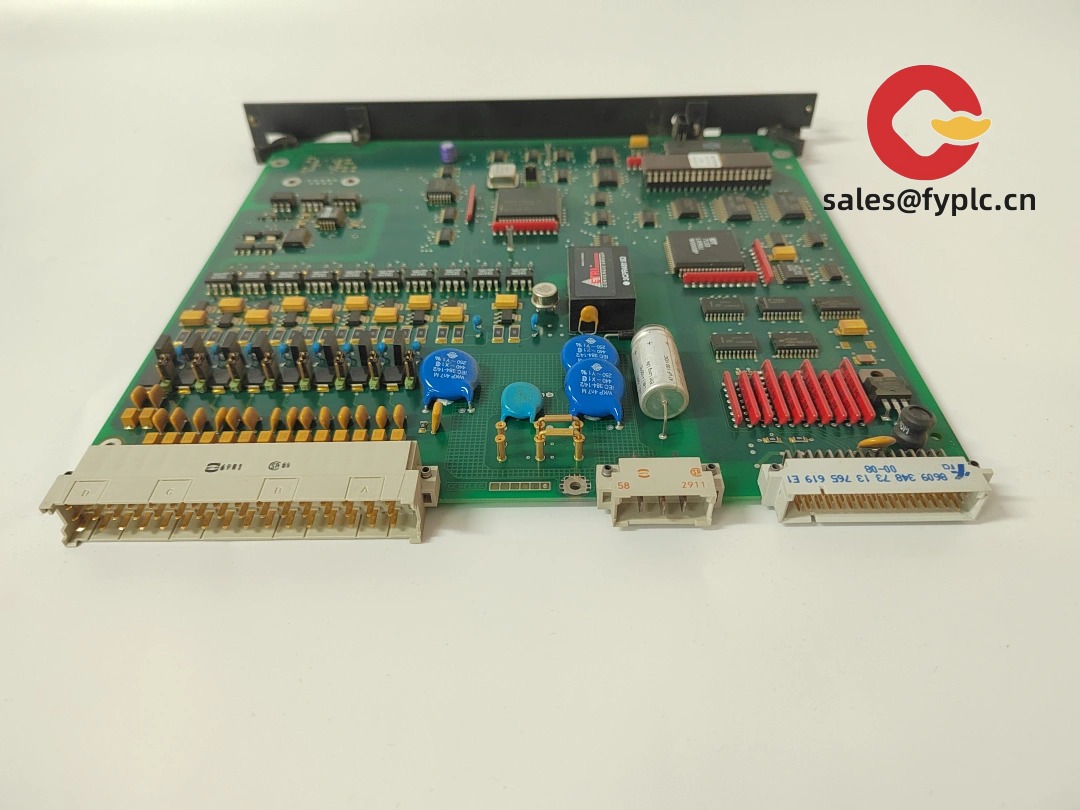

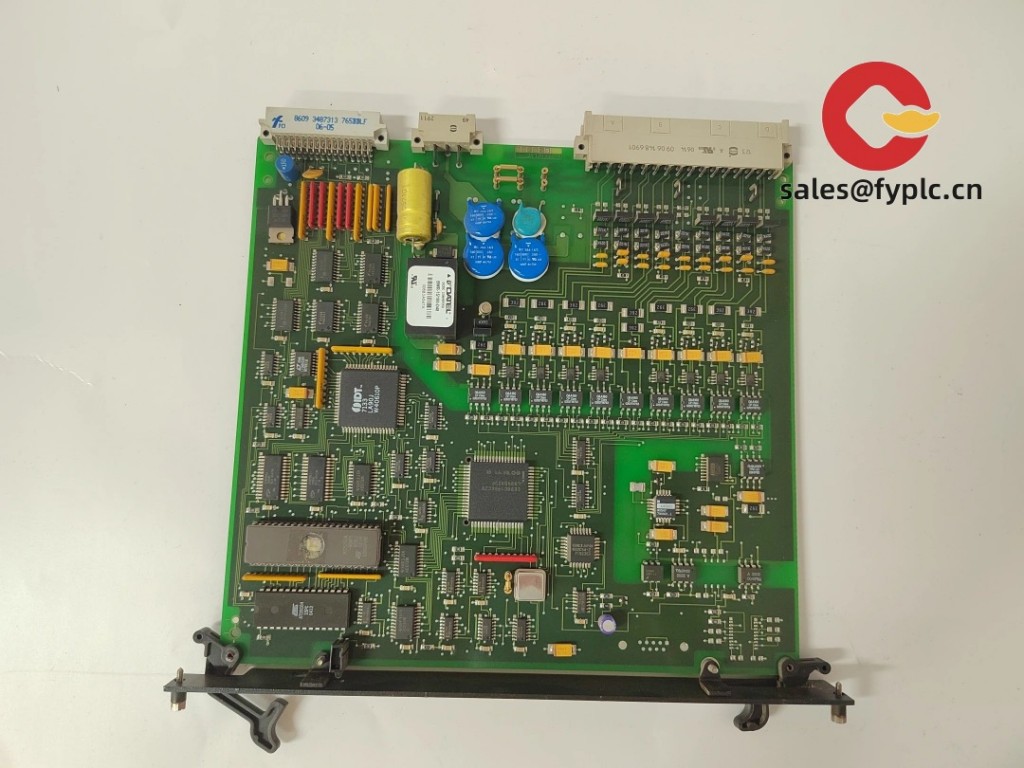

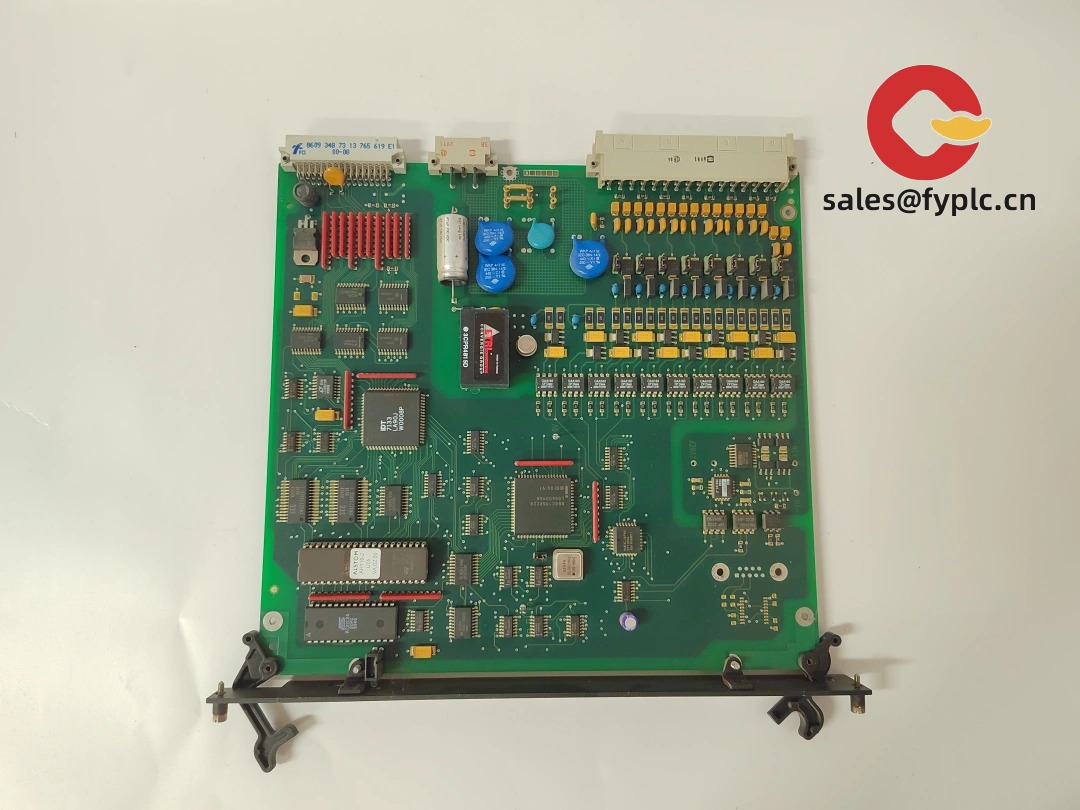

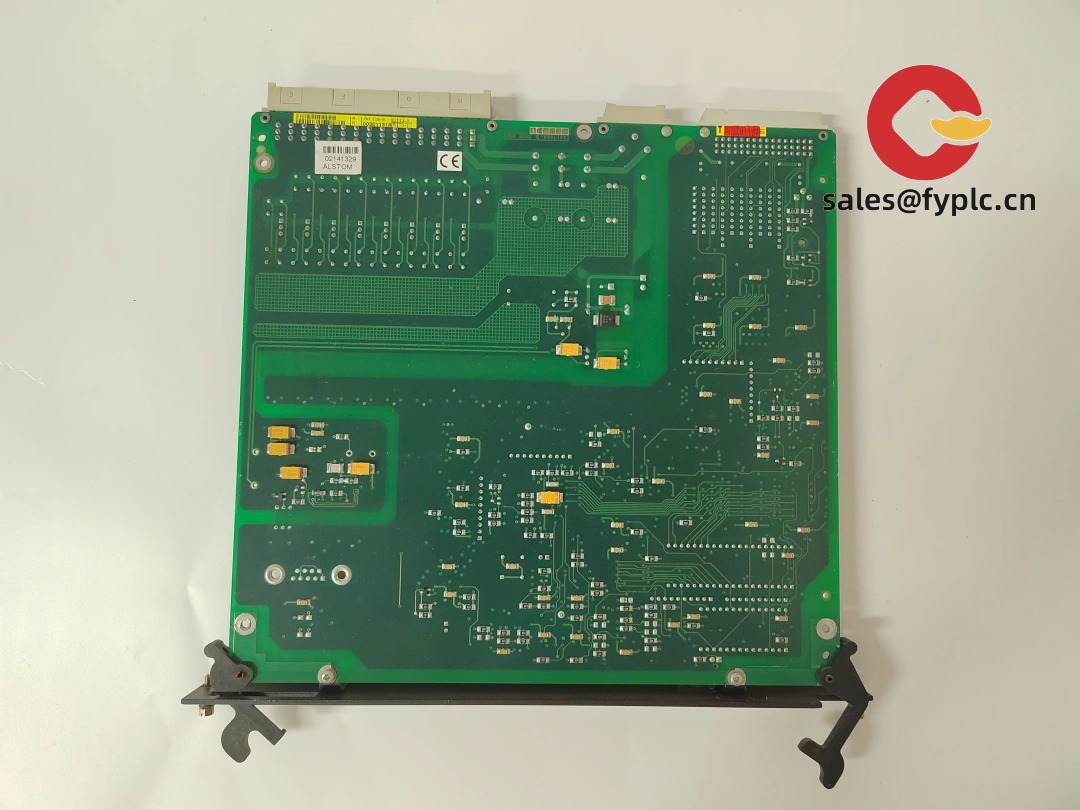

ALSTOM AH116-2 – Plug-in I/O Module for Legacy ALSTOM Turbine & Plant Controls

The ALSTOM AH116-2 is a plug-in control module used across many legacy ALSTOM platforms in power generation and process plants. From my experience, it typically serves as an I/O interface card within ALSTOM racks (often found in steam/gas turbine control cabinets and balance-of-plant systems), handling field signals and passing them deterministically to the controller via the backplane. You might notice the “-2” denotes a later hardware revision, which in many cases brings incremental robustness and lifecycle updates while preserving backward compatibility.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week for in-stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

- Traceability: Photos of the actual unit and test reports can be provided prior to dispatch, upon request

Key Features

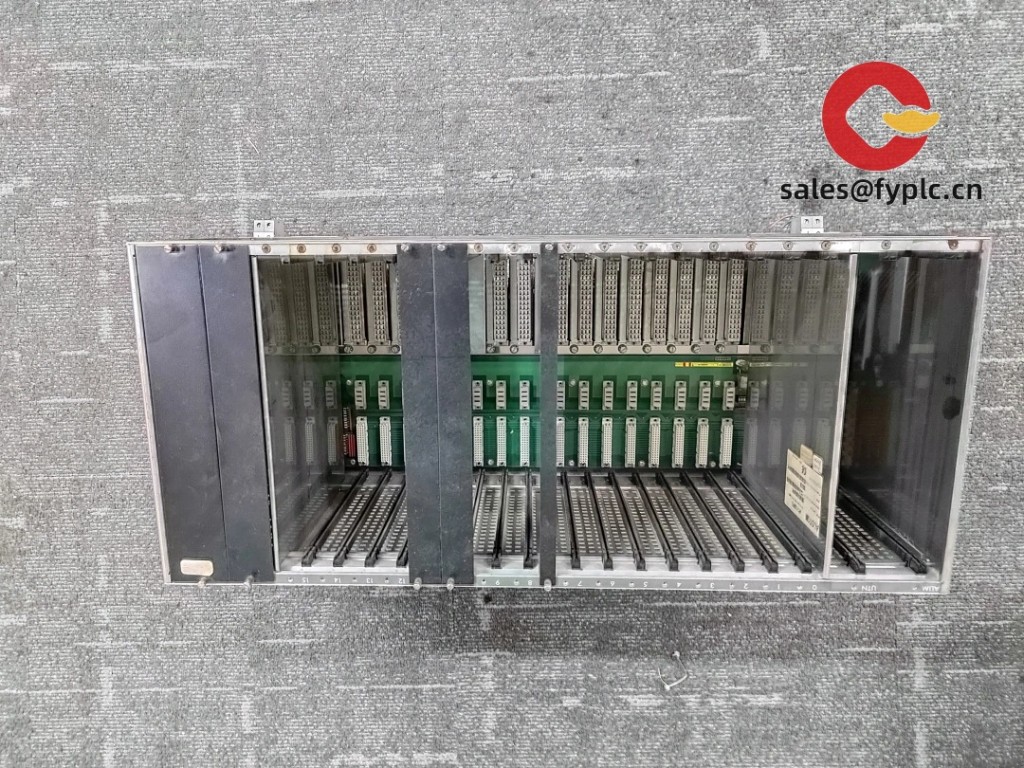

- Designed for ALSTOM legacy racks – Fits established ALSTOM control cabinets used in turbines and balance-of-plant, helping you replace like-for-like without redesign.

- Backplane integration – Communicates via the proprietary rack bus, so scan times and sequencing remain consistent with the original configuration.

- Signal handling commonly used in plants – Typically supports standard analog ranges (e.g., 4–20 mA / 0–10 V) and discrete signals found in process instrumentation; exact channel mix depends on build.

- Status and diagnostics – Front indicators and onboard checks provide quick visual verification during commissioning and troubleshooting.

- Service-friendly design – Plug-in replacement with front-access wiring allows faster swap-outs, which in many cases shortens planned maintenance windows.

- Revision “-2” hardware – Later revision that typically improves noise immunity and long-term maintainability while remaining form-fit compatible.

Technical Specifications

| Brand / Model | ALSTOM AH116-2 |

| Product Type | Plug-in I/O interface module for ALSTOM control racks (legacy platforms) |

| HS Code | 8538.90 (Parts suitable for apparatus of 8535/8536/8537) |

| Power Requirements | Backplane powered by host rack; in most cases the cabinet supply is 24 VDC. Consult site documentation for the exact rack voltage. |

| Dimensions & Weight | Plug-in module card; typical control-rack format with weight commonly under 1 kg. Physical size depends on the specific rack frame. |

| Operating Temperature | Typically 0–55°C when installed in a ventilated control cabinet |

| Signal I/O Types | Commonly analog 4–20 mA or 0–10 V and dry-contact digital I/O; channel count and ranges vary by build/version. |

| Communication Interfaces | Proprietary ALSTOM backplane bus; no external fieldbus on the module faceplate in most cases |

| Installation Method | Front-inserted plug-in card; de-energize the rack before removal unless your platform explicitly supports hot-swap |

Application Fields

The AH116-2 is typically encountered in:

- Steam and gas turbine control cabinets (governing, protection interfacing, and auxiliary systems)

- Balance-of-plant instrumentation: pumps, fans, valves, and heater controls in power stations

- Industrial steam plants and cogeneration units upgrading or maintaining ALSTOM legacy DCS

- Retrofit projects seeking drop-in replacements without requalification of wiring or logic

Advantages & Value

- Form-fit-function replacement – Keeps your existing wiring and logic intact, which usually eliminates costly re-engineering.

- Reduced downtime risk – Direct swap, proven field reliability, and known behavior in ALSTOM racks.

- Lifecycle support – Sourcing legacy modules avoids forced migrations when the rest of the system is stable.

- Technical support on demand – Pinout checks, parameter notes, and pre-shipment testing available to smooth commissioning.

Installation & Maintenance

- Cabinet standards – Install in the designated ALSTOM rack frame within a clean, ventilated control cabinet; maintain ambient typically within 0–55°C.

- Wiring & segregation – Route analog signals separately from power cables; use shielded pairs for 4–20 mA and ground shields at one point to limit noise.

- Power-down policy – Unless your platform explicitly supports hot-swap, isolate and de-energize before insertion/removal; observe ESD precautions.

- Routine checks – Verify terminal tightness and inspect connectors during outages; clean dust using dry air and avoid solvents on conformal coatings.

- Calibration/validation – For analog channels, validate scaling with a loop calibrator after replacement; document any range adjustments.

- Firmware/config – If the card holds configuration, back up and restore parameters; update only with approved rack firmware, if applicable.

Quality & Certifications

- Original ALSTOM part; CE marking is typical for supplied modules in this family

- RoHS status may vary by production year/revision; documentation can be provided on request

- Units undergo functional testing prior to shipment when requested

- Seller warranty: 12 months (365 days). OEM warranty subject to unit condition and supply source.

Note: Exact channel counts, electrical ranges, and pinouts for AH116-2 can vary by build. If you share a photo of your front label and rack part number, we’ll match the specification one-to-one before quoting, which in many cases avoids commissioning surprises.

Reviews

There are no reviews yet.