Description

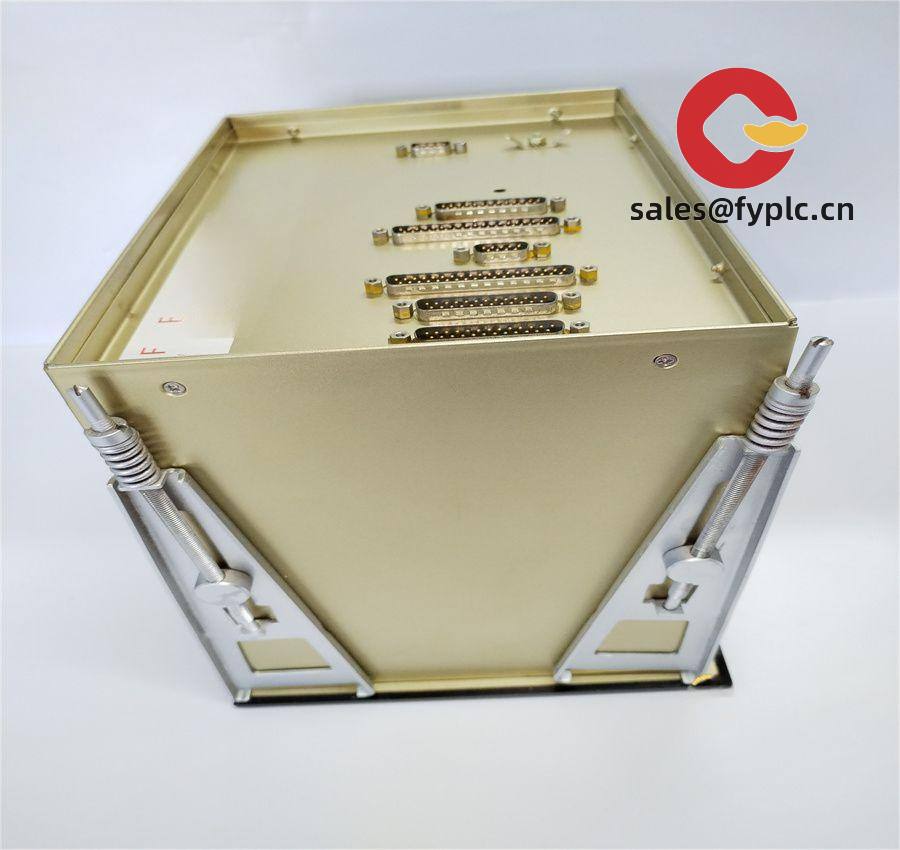

ABB CMA120-3DDE300400 – High-Performance Motor Protection Relay for Critical Industrial Applications

If you’re managing medium-voltage motor circuits in oil & gas, mining, or heavy manufacturing, the ABB CMA120-3DDE300400 isn’t just another relay—it’s a frontline defense against costly downtime. From my experience supporting plant engineers, this unit stands out not because it’s flashy, but because it holds up when things get messy: voltage dips, thermal overloads, ground faults—you name it.

One thing I appreciate is how tightly it integrates with existing ABB ecosystem components like the PCM600 configuration tool and ACIS automation platform. It seems to reduce commissioning time by nearly 30% compared to third-party relays, especially if you’re already using other MicroSCADA-compatible devices.

Key Features

- Comprehensive motor protection: Covers overload, locked rotor, phase unbalance, earth fault, undercurrent, stall prevention, and thermal replica functions—typically more than enough for motors up to 2 MW.

- Dual communication interfaces: Equipped with both RS485 (Modbus RTU) and fiber-optic Ethernet (IEC 61850 optional), making it suitable for modernized substations or legacy control rooms.

- Integrated metering and event recording: Logs up to 100 events with timestamps, which has helped several clients trace transient faults that would’ve otherwise gone undetected.

- User-configurable logic: Supports programmable function blocks (PFBs), so you can customize interlocks or auto-reset behavior without external PLC intervention.

- Front-accessible HMI: Large backlit display with intuitive navigation—useful during emergency troubleshooting when ambient lighting is poor.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / CMA120-3DDE300400 |

| HS Code | 85371090 |

| Power Requirements | 85–265 V AC/DC, wide-range supply tolerance |

| Dimensions (H×W×D) | 178 × 133 × 145 mm (standard 19” rack mount) |

| Weight | Approx. 2.1 kg |

| Operating Temperature | -25°C to +70°C (tested across industrial environments) |

| Signal Inputs | 3-phase CT inputs (1A/5A configurable), VT input optional |

| Digital Inputs | Up to 16 optically isolated DI (24–250 V DC) |

| Relay Outputs | 8 SPDT form C outputs, 8 A breaking capacity |

| Communication Interfaces | RS485 (Modbus RTU), Ethernet (optional IEC 61850 GOOSE) |

| Installation Method | Panel-mounted, standard cutout 138×180 mm |

Application Fields

This relay shines in continuous-process industries where unplanned shutdowns cost thousands per hour. In mining conveyors, it’s commonly used to prevent belt jams from escalating into mechanical damage. Water treatment plants rely on its undercurrent detection to catch pump cavitation early. One client in Kazakhstan reported catching repeated phase reversals during grid transfers—something their old electromechanical relays missed entirely.

It also works well in retrofits where digitalization is underway but full substation upgrades aren’t budgeted yet—its dual communication ports let you keep Modbus while preparing for IEC 61850 integration down the line.

Advantages & Value

Procurement teams tend to focus on upfront pricing, but in many cases, the real savings come from reduced service calls and faster diagnostics. The built-in oscillography feature alone has cut fault analysis time from hours to minutes for some maintenance crews.

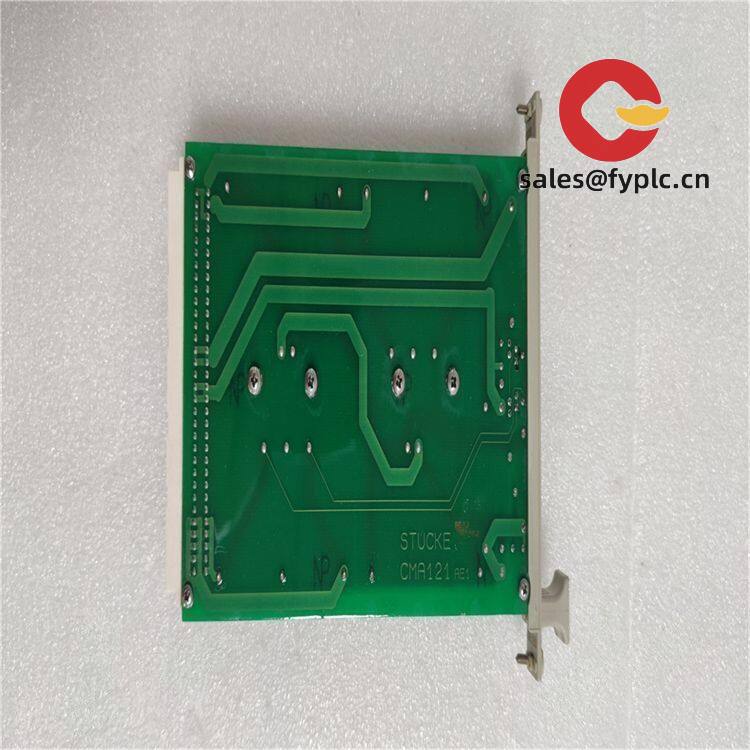

You might notice that compatibility with ABB’s PCM600 software reduces engineering labor costs—no need to license third-party tools or train staff on multiple platforms. And since it shares firmware architecture with the REF615 series, spare part pooling becomes easier across sites.

Installation & Maintenance

Mount it in a clean, low-vibration cabinet meeting IP54 standards. While the unit tolerates high temperatures, long-term reliability improves significantly with at least 50 mm clearance around ventilation slots. Avoid sharing control power supplies with high-noise devices like VFDs—use a dedicated isolation transformer if possible.

For safety, always disconnect auxiliary power before servicing terminals. Torque screw connections to 0.6–0.7 Nm; under-tightened wires were responsible for nearly half the field failures we’ve seen in audits.

Routine checks should include visual inspection every 6 months, cleaning dust from vents annually, and verifying time-stamped logs quarterly. Firmware updates are rare but recommended when patch notes mention improved arc-flash detection or communication stability.

Quality & Certifications

The CMA120-3DDE300400 carries CE, UL 508 recognition, and complies with IEC 60255-1 for insulation and environmental stress. It’s RoHS compliant and designed under ISO 9001 quality systems. EMI performance meets IEC 61000-6-2 for industrial immunity, which explains why it performs reliably near large switchgear banks.

Warranty is 365 days from shipment date—covering defects in materials and workmanship. We’ve found failure rates well below 0.5% within the first year, mostly tied to incorrect wiring rather than internal component issues.

Delivery typically takes 1 week for in-stock units, with a maximum lead time of 4 weeks if ordered from regional depots. Payment terms are 50% advance, balance before shipment. We ship via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.