Description

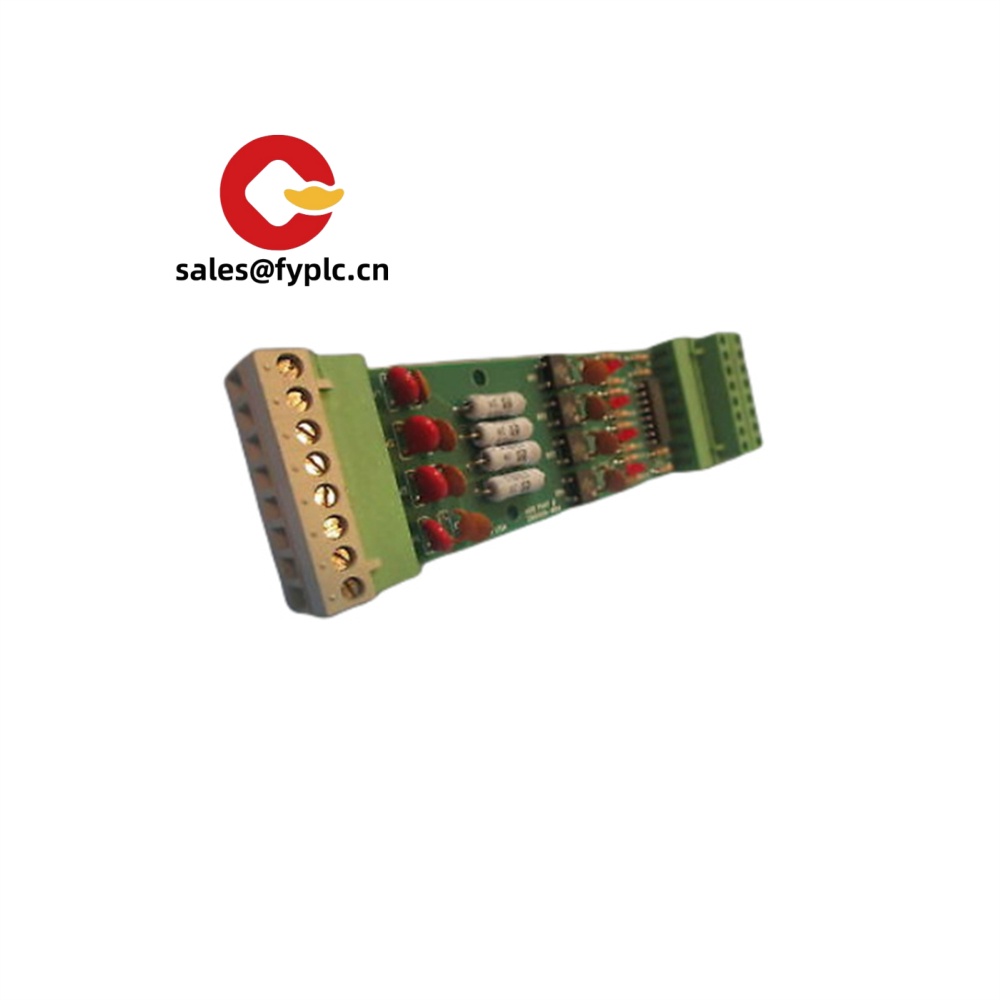

ABB 200900-004 – High-Performance Industrial Controller for Process Automation

If you’re managing legacy ABB automation systems—especially in power generation, water treatment, or oil & gas—you’ve likely come across the 200900-004. It’s not the newest module on the market, but it still holds its ground in many control cabinets I’ve seen in the field. This AC 410 controller is part of ABB’s Advant OCS series, designed for robust performance in continuous industrial environments where uptime matters.

Key Features

- Dedicated process control logic: Handles complex sequencing and regulatory control tasks, typically found in boiler management or pump station automation.

- Modular integration: Plugs directly into Advant OCS racks, making replacement or expansion relatively straightforward if your system already uses this platform.

- Analog and digital I/O support: Interfaces with standard 4–20 mA sensors and relay outputs, which simplifies wiring in retrofit scenarios.

- Firmware-based configuration: Programmed via ABB’s Systemware tools; one thing I appreciate is how consistent the diagnostic logging is once set up correctly.

- Redundancy-ready: In many cases, these are deployed in redundant pairs to minimize downtime—something end users in critical infrastructure really value.

Technical Specifications

| Brand/Model | ABB / 200900-004 |

| HS Code | 85371090 |

| Power Requirements | 24 VDC nominal (range: 19–30 VDC) |

| Dimensions & Weight | Approx. 120 x 200 x 60 mm, 0.8 kg |

| Operating Temperature | 0°C to +55°C (with derating above 45°C) |

| Signal Input/Output Types | Digital inputs (dry contact), analog inputs (4–20 mA, 0–10 V), relay outputs |

| Communication Interfaces | RS-485 (MODBUS RTU), proprietary ABB Fieldbus (for rack communication) |

| Installation Method | DIN rail mount within Advant OCS cabinet enclosures |

Application Fields

The 200900-004 shows up most often in aging—but still operational—process plants. From my experience, it’s commonly used in turbine control panels at regional power stations, chemical dosing systems in municipal water facilities, and as a primary sequencer in compressor skids. It seems to be especially prevalent in installations from the late 1990s through early 2000s. While newer DCS platforms have largely replaced it in greenfield projects, spare units are in steady demand for maintenance and temporary bridging during upgrades.

Advantages & Value

You might notice that sourcing an exact replacement like this isn’t just about functionality—it’s about avoiding a full system re-engineering effort. Keeping a 200900-004 in stock can save weeks of downtime and thousands in engineering labor. These modules are typically reliable when stored properly, and since they’re field-proven, there’s less risk of unexpected behavior compared to integrating a modern PLC with custom logic translation. Procurement teams tend to favor them for their compatibility and predictable lifecycle costs, especially when dealing with long-term service contracts.

Installation & Maintenance

When installing, make sure the DIN rail is securely mounted and the cabinet meets IP54 standards, particularly in humid or dusty environments. Ventilation matters—don’t stack heat-generating components nearby. Always disconnect power before insertion or removal; hot-swapping isn’t supported, and forcing it can damage the backplane. For maintenance, periodic visual inspection helps catch corrosion or loose terminals early. Firmware updates are rare but possible using ABB’s original engineering station setup. Calibration isn’t required for the module itself, but connected field instruments should follow your site’s routine schedule.

Quality & Certifications

Units we supply are tested and verified working, with a 365-day warranty. The original ABB design complies with CE, UL, and IEC 61131-2 standards for industrial control equipment. RoHS compliance may vary depending on manufacturing date, though most units from the 2000s onward meet exemption clauses under leaded solder use. We don’t offer new-old-stock with expired warranties—every module goes through functional testing before shipment.

Delivery typically takes one week for in-stock units; no longer than a month if a transfer is needed. We accept 50% advance payment, with full balance due upon dispatch. Shipment is via FedEx, UPS, or DHL—your choice based on urgency and location.

Reviews

There are no reviews yet.