Description

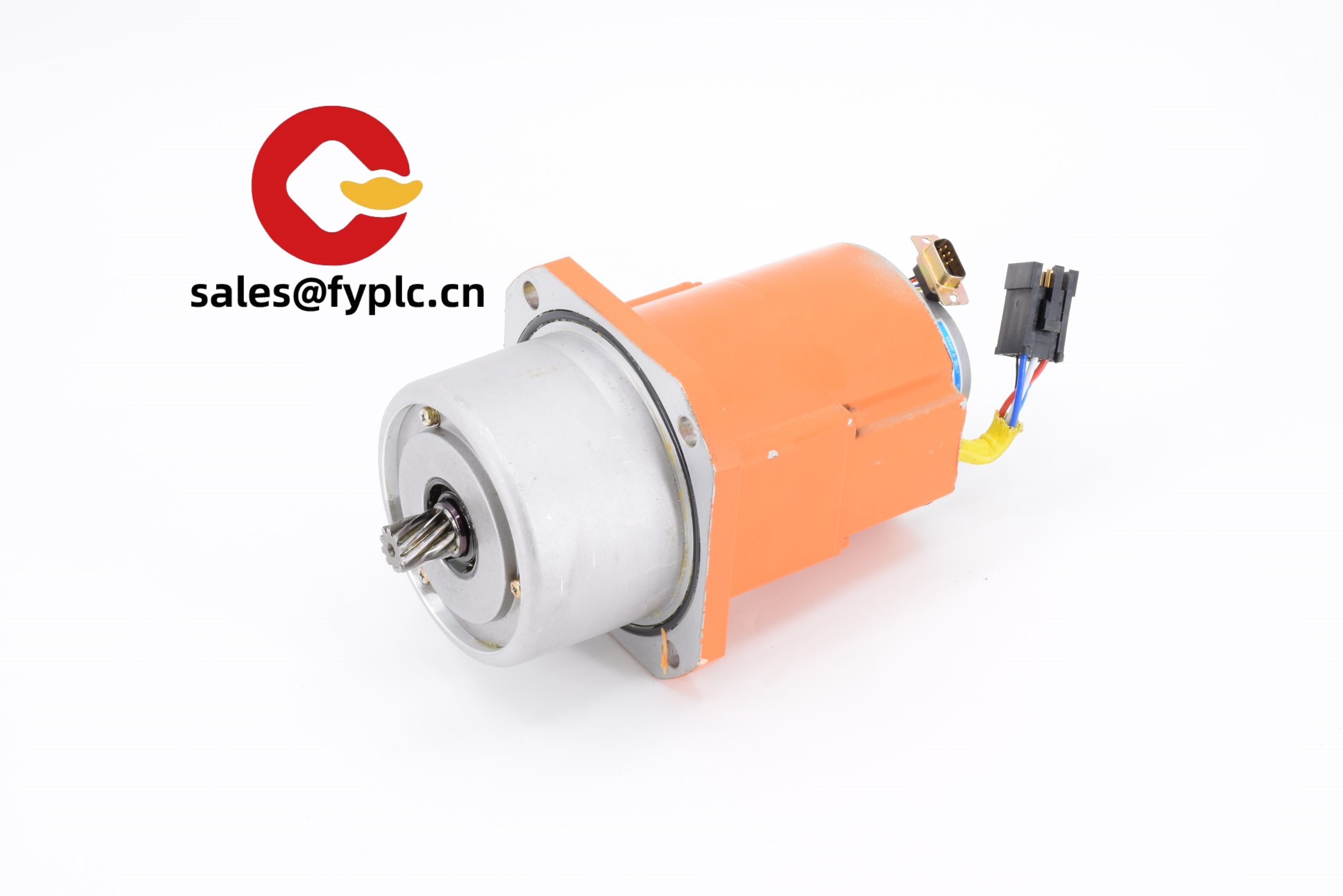

ABB 3HAC17326-1/02 – Servo Drive Module for Precision Motion Control

If you’re working on industrial automation systems that demand tight synchronization and responsive motor control, the ABB 3HAC17326-1/02 typically stands out as a reliable servo drive solution. It’s commonly used within ABB’s IRB robot ecosystems, especially in manufacturing environments where timing and positioning accuracy matter—like automotive assembly or CNC handling lines.

Key Features

- Compact design with high power density – Fits into tight control cabinets without sacrificing performance, which helps save panel space in retrofitted cells.

- Integrated safety functions – Supports STO (Safe Torque Off), making it easier to meet basic machine safety requirements without additional relays.

- Digital feedback interface – Works seamlessly with ABB’s resolver and encoder systems, reducing signal noise and improving position loop stability.

- Fieldbus-ready communication – Uses ABB’s internal DRIVE-TECH bus, allowing fast coordination between multiple axes in robotic applications.

- Thermal protection & diagnostics – Built-in sensors monitor temperature and current load, alerting controllers before overheating becomes an issue.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3HAC17326-1/02 |

| HS Code | 8537.10 |

| Power Requirements | DC 170–300 V nominal (from drive module supply) |

| Dimensions & Weight | Approx. 180 x 120 x 50 mm / 1.2 kg |

| Operating Temperature | 0°C to +45°C (derating may apply above 40°C) |

| Signal I/O Types | Digital inputs/outputs for enable, fault reset, status; analog monitoring outputs |

| Communication Interfaces | DRIVE-TECH (proprietary ABB serial motion bus), CAN-based |

| Installation Method | DIN rail or panel mount with grounding bracket |

Application Fields

From my experience, this module shows up most often in robotic workcells—particularly those using ABB IRB 1600 or IRB 2400 series arms. It drives individual joints with precise torque response, so tasks like arc welding, material handling, or machine tending benefit significantly. You might also find it in standalone automation setups where someone is replicating ABB’s original drive architecture for spare capacity or system expansion.

One thing I appreciate is how well it integrates with RobotWare. Once configured, it tends to run silently in the background—no constant tuning needed under normal loads.

Advantages & Value

In many cases, replacing a failed servo axis quickly means minimizing downtime. The 3HAC17326-1/02 isn’t always the cheapest option on the market, but its plug-and-play compatibility with existing ABB cabinets usually makes it the fastest path back to production. There’s less risk of firmware mismatch or configuration drift compared to third-party alternatives.

Procurement teams tend to favor keeping these in stock—not because they fail often, but because when one does go down, the line stops. Having a known-good unit available cuts troubleshooting time dramatically.

Installation & Maintenance

Mount it in a clean, well-ventilated cabinet—IP20 minimum. Avoid placing near heat-generating components like transformers or frequency converters. Make sure the DIN rail is properly grounded, and double-check the DC link voltage before powering up; incorrect supply is one of the more common causes of premature failure.

Periodic checks should include cleaning dust from heatsinks and verifying secure terminal connections. While there’s no user-serviceable calibration, occasional firmware updates through RobotStudio can improve responsiveness or add diagnostic features.

Quality & Certifications

The unit carries CE, UL, and RoHS compliance markings, indicating it meets standard industrial safety and environmental directives. It appears that ABB maintains ISO 9001 processes across its drive manufacturing sites, which adds confidence in long-term reliability.

Our warranty covers 365 days from shipment—covering defects in materials and workmanship, assuming proper installation and operating conditions. No extended service plans, but we do offer technical documentation support upon request.

Order Placement & Delivery

For in-stock units, delivery typically takes about one week via FedEx, UPS, or DHL—depending on destination. Lead time won’t exceed one month even for backordered items. Payment requires 50% upfront, with the balance due before shipment. We don’t accept open POs or net terms unless pre-arranged.

Reviews

There are no reviews yet.