Description

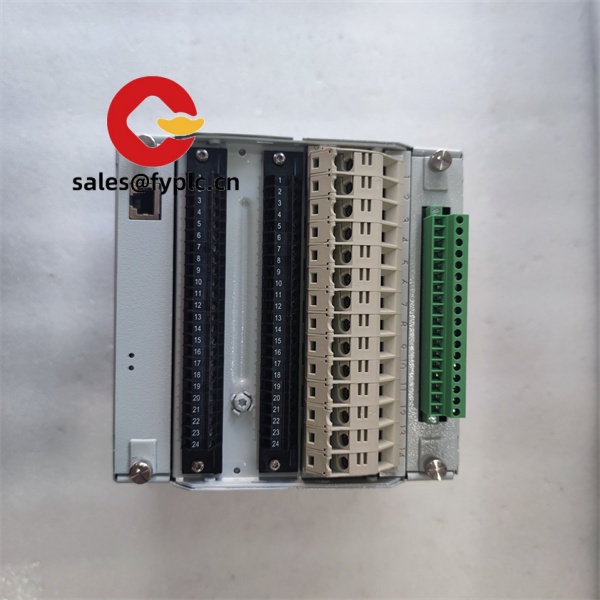

ABB PDP22-FBP – Distributed I/O Power Distribution Panel for Industrial Automation Systems

If you’re building or maintaining a modular automation setup using ABB’s System 800xA or AC 800M controllers, the PDP22-FBP is one of those behind-the-scenes components that quietly ensures everything runs without a hitch. It’s not flashy, but in many cases, it’s what keeps your distributed I/O racks powered reliably across harsh industrial environments.

One thing I appreciate about this unit is how it simplifies power distribution within an I/O station—especially when dealing with冗长的信号链路 (long signal chains). You might notice that without proper segmentation, voltage drops can become an issue over extended backplane configurations. The PDP22-FBP helps mitigate that by acting as a mid-segment power injector.

Key Features

- Distributed Power Injection: Designed to supply auxiliary power midway through an I/O segment, reducing voltage drop across long Profibus DP or Modbus segments.

- Modular Integration: Mounts directly on standard DIN rails and integrates seamlessly with ABB’s Symphony Plus and 800xA I/O subsystems.

- Redundant Supply Support: Accepts dual input voltages (typically 24 VDC), allowing for redundancy in mission-critical applications.

- Backplane Isolation: Provides galvanic isolation between segments, which typically improves noise immunity in electrically noisy plants.

- Status Indication: LED indicators show power status and fault conditions—handy during commissioning or troubleshooting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / PDP22-FBP |

| HS Code | 85371090 |

| Power Requirements | Dual 24 VDC inputs (redundant), max load current per segment: ~2 A |

| Dimensions & Weight | Approx. 40 mm width, 125 mm height, 115 mm depth; ~0.3 kg |

| Operating Temperature | -25°C to +60°C (with derating above 55°C) |

| Signal Input/Output Types | None (power-only module); interfaces via backplane coupling |

| Communication Interfaces | N/A – passive power distribution unit |

| Installation Method | Top-hat DIN rail (35 mm), vertical mounting recommended for airflow |

Application Fields

From my experience, the PDP22-FBP shows up most often in large-scale process automation systems—particularly in oil & gas terminals, power generation facilities, and water treatment plants where I/O cabinets are spread out over hundreds of meters. It’s commonly used when extending remote I/O segments beyond 32 modules, where native backplane power starts to degrade. In these setups, placing a PDP22-FBP every 16–32 modules maintains stable voltage levels and avoids intermittent communication faults.

Advantages & Value

While it may seem like just another power splitter, its real value lies in system stability. Procurement teams typically appreciate that it reduces fieldbus errors caused by low voltage—cutting down on unplanned downtime and service calls. Because it’s an official ABB component, compatibility isn’t a guessing game. That means less risk during integration and faster commissioning times. Over time, avoiding even one shutdown event tends to justify the cost.

Installation & Maintenance

Install it in a control cabinet meeting IP54 standards, preferably with adequate ventilation since heat buildup can shorten lifespan—even though the unit itself doesn’t generate much. Make sure both power feeds come from separate redundant power supplies if high availability is required. Wiring should use minimum 1.5 mm² stranded copper conductors, properly torqued to avoid loose connections.

Routine checks should include verifying LED status monthly and cleaning dust from vents annually. There’s no firmware to update, but it’s worth checking terminal tightness during scheduled maintenance cycles—vibration in industrial settings sometimes loosens screws over time.

Quality & Certifications

The PDP22-FBP carries CE, UL, and ATEX markings (for hazardous areas when installed per guidelines), and complies with IEC 61131 and IEC 61000 standards for electromagnetic compatibility. It appears to be RoHS compliant based on ABB’s public documentation. Our warranty covers 365 days from shipment date—typical for genuine ABB spares.

Our Order Placement Process and Guarantees

- Warranty Period: 365 days

- Delivery Time: 1 week for in-stock units; no more than one month at the latest

- Payment Method: 50% advance payment, balance before delivery

- Express Delivery: FedEx, UPS, or DHL (choice depends on destination and urgency)

Reviews

There are no reviews yet.