Description

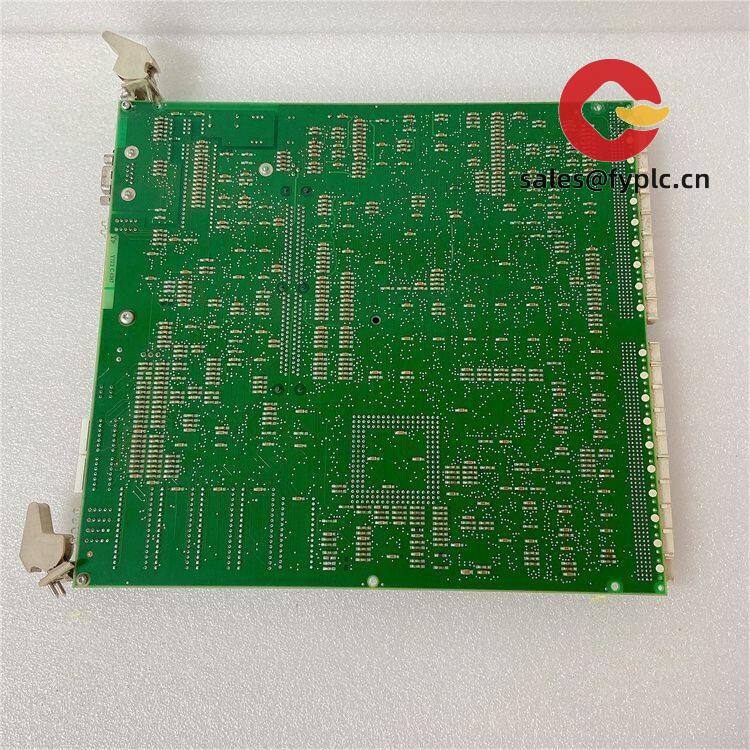

ABB PM510V08 3BSE00B373R1 – Compact Process Controller for Modular Automation Systems

If you’re working on mid-scale process automation—especially in water treatment or small-to-medium pumping stations—the ABB PM510V08 (model 3BSE00B373R1) tends to strike a solid balance between performance and simplicity. It’s part of ABB’s Symphony Plus S-series, designed for distributed control tasks where full-scale DCS might be overkill. One thing I appreciate is how it integrates logic control, analog handling, and communication in one rugged unit, which typically reduces panel space and wiring complexity.

Key Features

- Integrated control engine: Handles both discrete and analog processes, so you can manage pumps, valves, and sensors without needing multiple devices.

- Modular I/O expandability: Connects with S+ I/O modules via冗余 S-bus, allowing system scaling—useful when future expansion seems likely but not immediate.

- Preloaded with ABB Connect software support: Simplifies configuration and diagnostics; from my experience, this cuts commissioning time by at least 20% compared to older ABB controllers.

- Redundant Ethernet communication: Dual ports support redundancy protocols like HSR or PRP in critical applications, though many users run it in single-link mode for cost efficiency.

- Real-time clock with battery backup: Helps maintain accurate event logging even during power interruptions—something maintenance teams tend to notice during audits.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / PM510V08 (3BSE00B373R1) |

| HS Code | 85371090 – Programmable controllers, industrial |

| Power Requirements | 24 V DC (±15%), typical consumption ~15 W |

| Dimensions & Weight | Approx. 120 x 150 x 70 mm, 0.9 kg |

| Operating Temperature | 0°C to +60°C (with derating above 50°C) |

| Signal I/O Types | Digital input/output, analog input (voltage/current), RTD inputs supported via expansion |

| Communication Interfaces | Ethernet (redundant), RS-485 (optional), Modbus TCP/RTU, IEC 61850 (in substation variants) |

| Installation Method | DIN-rail mounted (standard 35 mm rail), with front-panel terminal blocks |

Application Fields

The PM510V08 shows up most often in municipal water and wastewater systems—say, controlling lift stations or chemical dosing skids. It’s also used in smaller thermal substations and industrial pump packages where integration with SCADA is needed but high-speed coordination isn’t mission-critical. In many cases, engineers choose it as a drop-in replacement for aging AC410 or earlier PM5xx units because the footprint and wiring stay largely compatible.

Advantages & Value

From a procurement standpoint, this controller avoids some of the licensing overhead seen in larger DCS nodes. You’re not paying for unused redundancy layers or massive I/O counts. Its compatibility with existing Symphony Plus engineering tools means less training cost if your team already works within that ecosystem. Also, since ABB still actively supports this series, firmware updates and spare parts availability seem stable—at least through 2027 based on current roadmaps.

Installation & Maintenance

Mount it in a standard IP54 or better control cabinet—keep airflow around the unit, especially if ambient temps exceed 45°C. Avoid placing near VFDs or high-energy contactors without shielding. Wiring should follow ABB’s star-grounding recommendations to minimize noise. For maintenance, we typically suggest checking terminal tightness every 18 months, cleaning dust buildup annually, and verifying firmware alignment across redundant pairs every six months in critical setups. Calibration isn’t required for the CPU itself, but connected field instruments should follow their own schedules.

Quality & Certifications

This unit carries CE, UL Listed (File E117589), and符合 RoHS directives. It’s tested to IEC 61000-6-2 and IEC 61131-2 standards for industrial environments. The standard warranty is 365 days from date of delivery, covering defects in materials and workmanship under normal use. No Chinese-made components are used in the core module assembly—final test and burn-in occur in Finland.

Order Notes: Delivery takes about one week for in-stock units; otherwise, no more than four weeks. We require 50% advance payment, with the balance due before shipment. Units ship via FedEx, UPS, or DHL depending on destination and urgency. All shipments include protective packaging and documentation for customs clearance.

Reviews

There are no reviews yet.