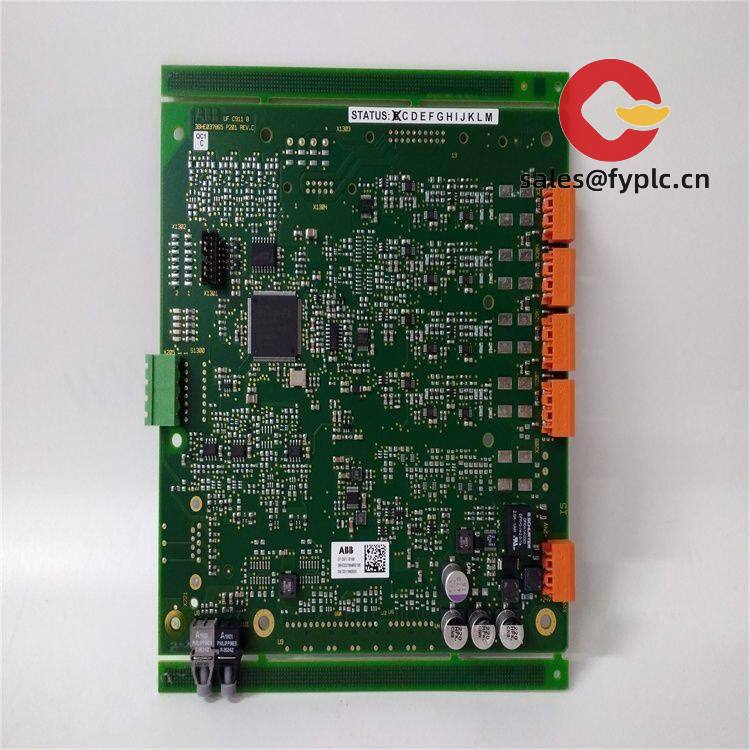

Description

ABB UFC911B108 (3BHE037864R0108) – Universal Field Controller for Modular Automation Systems

If you’re working on retrofitting or expanding an ABB 800xA system, the UFC911B108 is one controller that tends to show up where flexibility and field integration matter most. It’s not flashy, but in many cases, it’s the kind of module that keeps distributed I/O networks running smoothly across demanding environments—especially when you’re dealing with mixed signal types and need reliable communication backbone support.

Key Features

- Modular Integration: Designed specifically for ABB’s Symphony Plus and 800xA systems, this unit slots into standard chassis setups and communicates seamlessly with AC 800M controllers via Profibus or Ethernet links.

- Mixed I/O Support: Handles both analog and digital field signals—typically used for monitoring temperature, pressure, and valve positions from remote locations.

- Diagnostics & Redundancy: Features onboard status indicators and supports redundancy configurations, which helps reduce downtime during unexpected failures.

- Firmware Flexibility: Can be updated through System Control Center (SCC) tools, allowing gradual upgrades without full system reboots in most cases.

- Secure Configuration: Uses ABB’s standard password-protected engineering access, helping prevent unauthorized changes in live environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / UFC911B108 (3BHE037864R0108) |

| HS Code | 85371090 |

| Power Requirements | 24 VDC nominal (range: 19.2–30 VDC), typically draws ~250 mA |

| Dimensions & Weight | Approx. 120 x 150 x 45 mm, 0.6 kg |

| Operating Temperature | 0°C to +60°C (storage: -40°C to +85°C) |

| Signal Input/Output Types | Supports AI, AO, DI, DO via connected I/O modules (not standalone) |

| Communication Interfaces | PROFIBUS DP-V1, Modbus RTU/TCP, Ethernet/IP (via controller network) |

| Installation Method | DIN-rail mounted within compatible ABB control cabinet (e.g., S800 I/O stations) |

Application Fields

You’ll typically find the UFC911B108 deployed in power generation plants, water treatment facilities, and oil & gas processing units—anywhere ABB’s distributed control architecture is used to manage complex processes. From my experience, it performs especially well in applications requiring real-time coordination between motor controls and process sensors, such as pump sequencing or boiler feedwater regulation. One thing I appreciate is how it integrates legacy field devices into modern control networks without requiring complete hardware overhauls.

Advantages & Value

Procurement teams tend to favor this model because it reduces integration risk. Since it’s part of ABB’s standardized ecosystem, compatibility issues are minimal compared to third-party alternatives. In many cases, using the UFC911B108 can cut engineering time by weeks during system expansions. There’s also long-term cost value—the firmware update path is supported through ABB’s regular release cycle, so obsolescence isn’t a pressing concern yet. Plus, spare parts availability remains strong globally, which simplifies inventory planning.

Installation & Maintenance

Install only in clean, dry cabinets meeting IP20 standards. Adequate ventilation around the module is recommended—don’t stack heat-generating components directly adjacent. Wiring should follow ABB’s segregation guidelines (separate high and low voltage runs). Before powering up, double-check terminal block connections; loose wires are the most common cause of intermittent faults we’ve seen in field reports. For maintenance, periodic visual inspection and firmware audits every 6–12 months help catch issues early. Calibration isn’t required for the controller itself, but connected field instruments should follow site-specific schedules.

Quality & Certifications

Certified to CE, UL, and RoHS standards—suitable for industrial use in North America, Europe, and much of Asia. Complies with IEC 61131-2 and IEC 61000-6 for electromagnetic compatibility. The manufacturer warranty covers defects in materials and workmanship for 365 days from shipment date. We’ve had very few returns on these units—most reported issues trace back to configuration errors rather than hardware failure.

Ordering Notes: Delivery takes about one week if in stock; otherwise, no more than four weeks. Payment requires 50% upfront, with the balance due before shipment. We ship via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.