Description

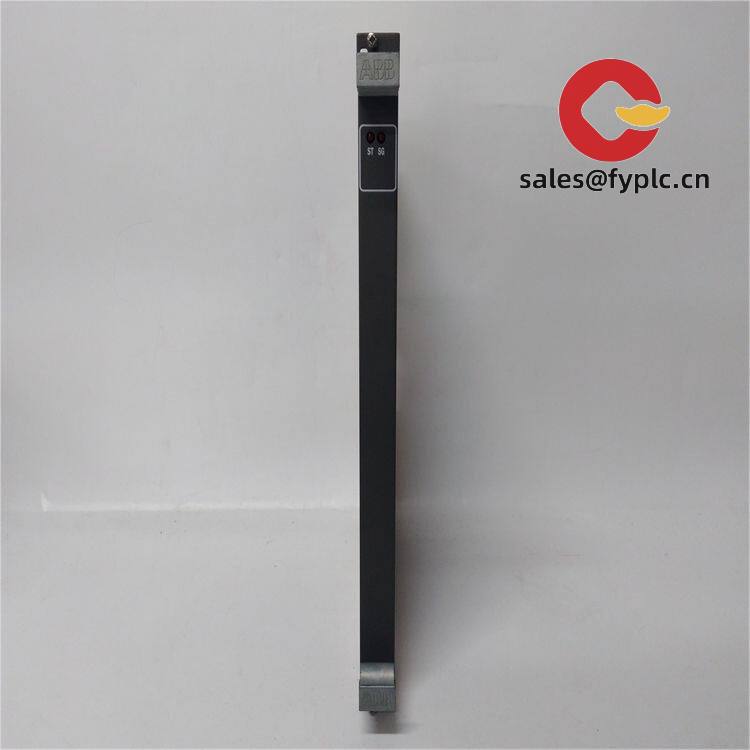

MSR04X1 – Compact Industrial Relay Module for Reliable Control Automation

If you’re working on a mid-density automation setup where space matters but reliability can’t be compromised, the MSR04X1 tends to fit right in. It’s not the flashiest module out there, but from what I’ve seen across packaging lines and small-scale PLC retrofits, it holds up well under repeated cycling and fluctuating load conditions.

Key Features

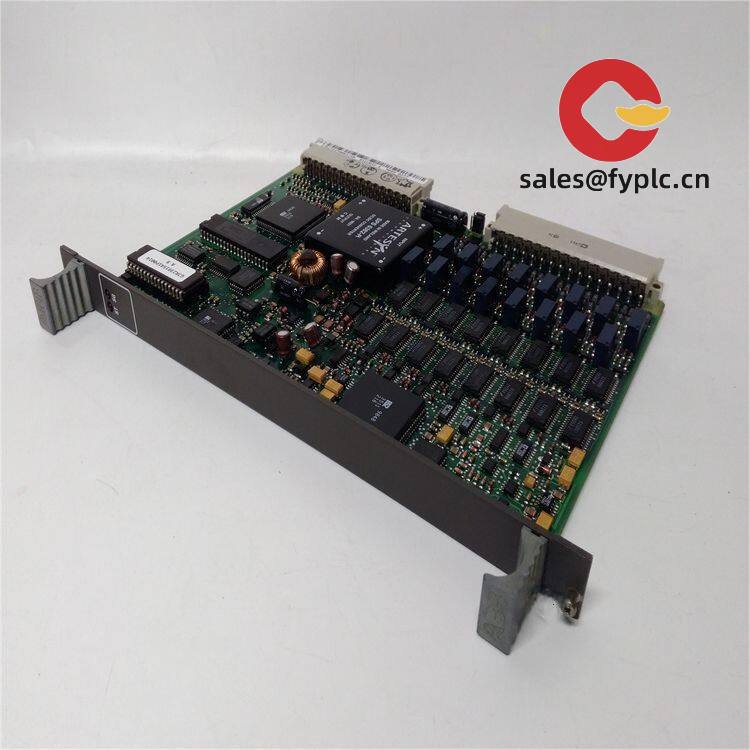

- 4-channel relay output: Handles up to 4 isolated loads, typically used for driving contactors, solenoids, or indicator circuits. Each channel is rated at 2A/250VAC, which covers most auxiliary control needs.

- DIN-rail mountable: Fits standard 35mm TS-35 rails—common in control cabinets. One thing I appreciate is how quickly it snaps in without needing extra brackets.

- LED status indicators: Per-channel LEDs make troubleshooting faster. You might notice that during commissioning, this cuts down diagnostic time significantly, especially in low-light panels.

- Optically isolated inputs: Accepts 12–24VDC control signals with noise immunity, which helps prevent false triggering in electrically noisy environments like pump stations or conveyor systems.

- Compact footprint: At just over 40mm wide, it frees up space in crowded enclosures—something that matters when upgrading legacy systems without replacing the entire cabinet.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / MSR04X1 |

| HS Code | 8536.50.90 (Electromagnetic relays, other) |

| Power Requirements | 24VDC ±15%, max 45mA typical draw |

| Dimensions (W×H×D) | 42mm × 90mm × 60mm |

| Weight | Approx. 120g |

| Operating Temperature | -20°C to +60°C (no condensation) |

| Signal Input Type | Dry contact or 12–24VDC active input |

| Output Type | 4× SPDT mechanical relays (2A @ 250VAC) |

| Installation Method | Top-hat DIN rail (35mm) |

Application Fields

The MSR04X1 shows up a lot in smaller-scale industrial applications—think machine tool controls, HVAC interlocks, or remote monitoring panels in water treatment sites. In many cases, it’s used as an output expander for compact PLCs that don’t have enough built-in relays. Some customers also use it in backup generator control logic or lighting automation within utility substations. It’s not designed for high-speed switching, but for general-purpose on/off control, it performs consistently.

Advantages & Value

Procurement teams tend to favor this model because it strikes a balance between cost and durability. While not branded like Omron or Siemens, it’s compatible with most 24VDC control architectures and avoids vendor lock-in. From my experience, projects with tight budgets but strict delivery timelines often go with the MSR04X1—it’s usually in stock, and replacements are easy to source. Also, since it uses standard footprints and wiring, training new technicians takes less time.

Installation & Maintenance

Mount it in a sealed control cabinet meeting IP54 or higher, especially if installed in humid or dusty areas. Ensure at least 10mm clearance on both sides for heat dissipation—relays do generate some internal heat during continuous operation. Use ferrules on wire ends to prevent loosening over time. No special tools needed for installation, just a flathead screwdriver for terminal tightening.

For maintenance, visually inspect every 6 months—check for discoloration, loose wires, or excessive relay chatter. Calibration isn’t required since it’s a passive switching device, but firmware isn’t applicable here (no microprocessor). Just keep the terminals clean and retightened periodically.

Quality & Certifications

The unit carries CE marking and complies with RoHS directives, indicating it meets basic EMC and environmental safety standards. It’s tested to withstand surge, ESD, and fast transient bursts per IEC 61000-4 series. There’s no UL listing, so it’s typically deployed in non-safety-critical roles unless backed by additional protective circuitry.

Comes with a 365-day warranty against manufacturing defects. If a channel fails prematurely under normal operating conditions, we’ll replace it—no questions asked. Most failures we see are due to overloading or incorrect voltage, so staying within spec really does extend lifespan.

Ordering Info & Delivery

Standard lead time is one week for in-stock units. If ordered today, expect delivery within 7–10 business days via FedEx, UPS, or DHL—tracking provided. For larger batches, maximum wait is under one month. Payment is 50% upfront, with the balance due before shipment. We don’t ship until full payment clears, but we hold stock for confirmed orders.

Reviews

There are no reviews yet.