Description

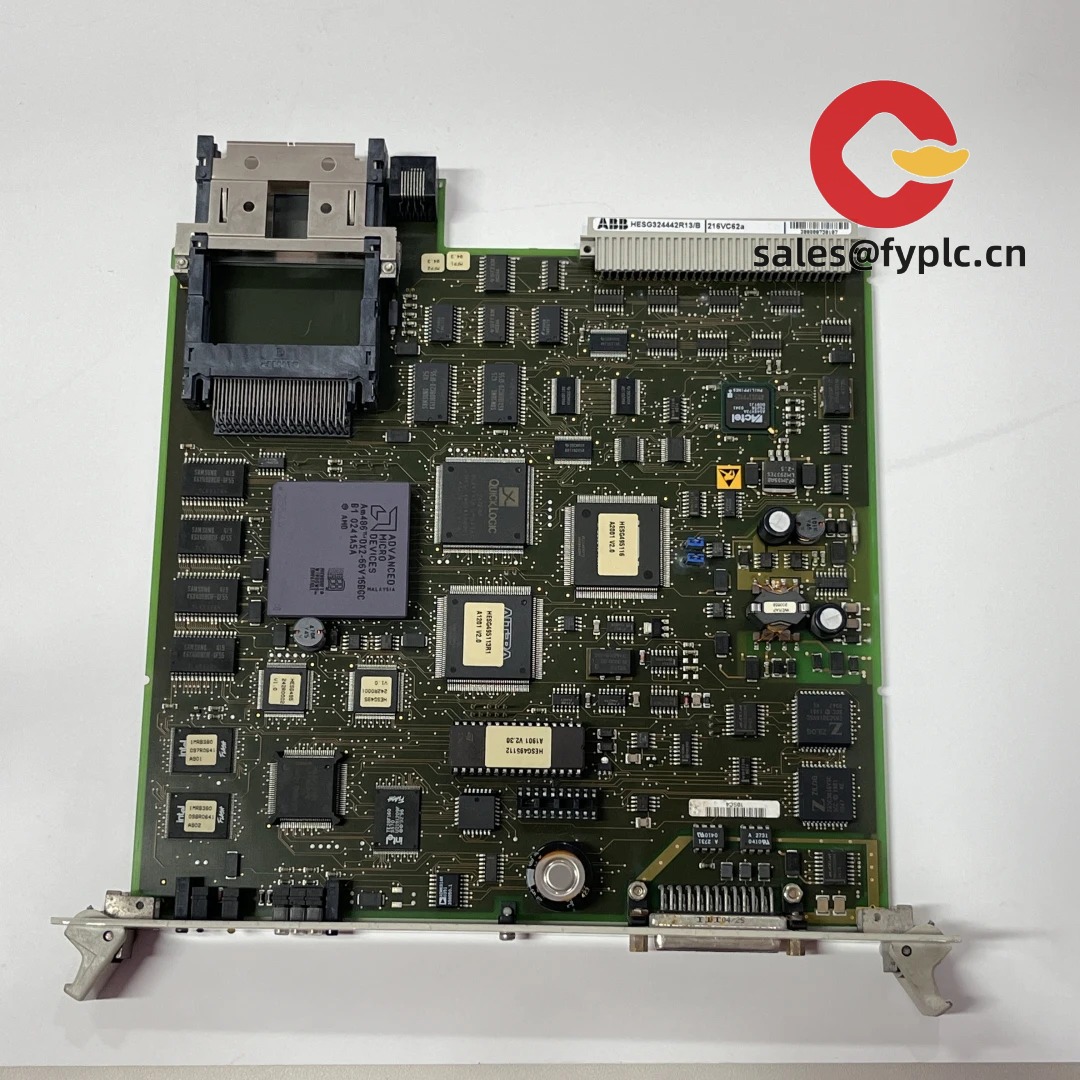

ABB 216VC62a/P1000 HESG324442R112 – Compact AC Drive for Precision Motor Control

The ABB 216VC62a/P1000 (HESG324442R112) is a compact, micro-sized variable frequency drive designed for light industrial motor control—particularly in applications where space is tight and reliability matters. It’s part of ABB’s well-regarded ACS150 series, which targets simple speed control tasks across HVAC, small conveyors, pumps, and fan systems. From my experience, this model tends to show up most often in retrofit projects or OEM equipment where plug-and-play performance is expected without the need for complex programming.

Key Features

- Compact footprint: Fits into small control cabinets—ideal when panel space is at a premium. One thing I appreciate is how easily it integrates alongside other components without requiring major layout changes.

- Integrated RFI filter: Helps meet electromagnetic compatibility standards right out of the box, reducing additional component costs in many cases.

- Pre-programmed macros: Includes factory presets for common setups like pump, fan, and manual/automatic control—cuts commissioning time significantly.

- Modbus RTU via RS-485: Offers straightforward communication with PLCs or building management systems. You might notice that integration with older SCADA setups tends to go smoothly with this one.

- Thermal protection & stall prevention: Built-in motor protection functions help avoid downtime due to overheating or sudden load changes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 216VC62a/P1000 (HESG324442R112) |

| HS Code | 85371090 |

| Power Rating | 0.75 kW / 1 HP @ 230 VAC |

| Input Voltage | Single-phase 200–240 VAC ±10% |

| Output Frequency | 0–500 Hz |

| Communication Interface | RS-485 (Modbus RTU) |

| Control Method | V/F Control with scalar mode |

| Installation Method | DIN rail or panel mount (with optional adapter) |

| Operating Temperature | 0°C to +50°C (derating above 40°C typical) |

| Dimensions (W×H×D) | 70 × 146 × 135 mm |

| Weight | Approx. 0.9 kg |

Application Fields

This drive typically appears in low-power automation environments. Think small ventilation fans in commercial buildings, circulation pumps in heating systems, or conveyor belts in packaging lines. It’s also used in test benches and laboratory equipment where precise but modest motor control is needed. In some cases, we’ve seen it replace older mechanical throttling systems—delivering energy savings through soft-start and variable speed operation.

Advantages & Value

Procurement teams tend to favor this unit because it strikes a balance between cost and functionality. While not as advanced as the ACS880 series, it delivers consistent performance for basic tasks. Compatibility with standard Modbus networks means fewer integration headaches. And since ABB still actively supports the ACS150 line, firmware updates and spare parts are generally available. From a lifecycle standpoint, replacing contactors or soft starters with this drive can reduce wear on motors and lead to measurable energy reductions—especially in variable-torque applications.

Installation & Maintenance

Mount vertically with at least 10 mm clearance on each side for airflow. Avoid placing directly above heat-generating components like transformers. Use shielded cables for motor leads if EMI is a concern—though the built-in RFI filter handles most residential or light commercial settings fine. Keep the environment clean and dry; dust buildup can impair cooling over time. No routine calibration is needed, but checking parameter backups every 6–12 months is a good practice. Firmware updates are rare but do exist—typically addressing communication stability or safety logic improvements.

Quality & Certifications

Certified to CE, UL Listed (for use in North America), RoHS compliant, and designed under ISO 9001 quality standards. The unit comes with a standard 365-day warranty covering defects in materials and workmanship. Repairs or replacements are handled directly through authorized service centers, though many end users opt for full-unit swaps due to labor cost efficiency.

Order Placement & Guarantees

Units in stock ship within one week. For out-of-stock items, lead time won’t exceed four weeks. We require 50% advance payment to confirm orders, with full balance due before shipment. All units are tested prior to dispatch. Express shipping via FedEx, UPS, or DHL included based on destination and urgency.

Reviews

There are no reviews yet.