Description

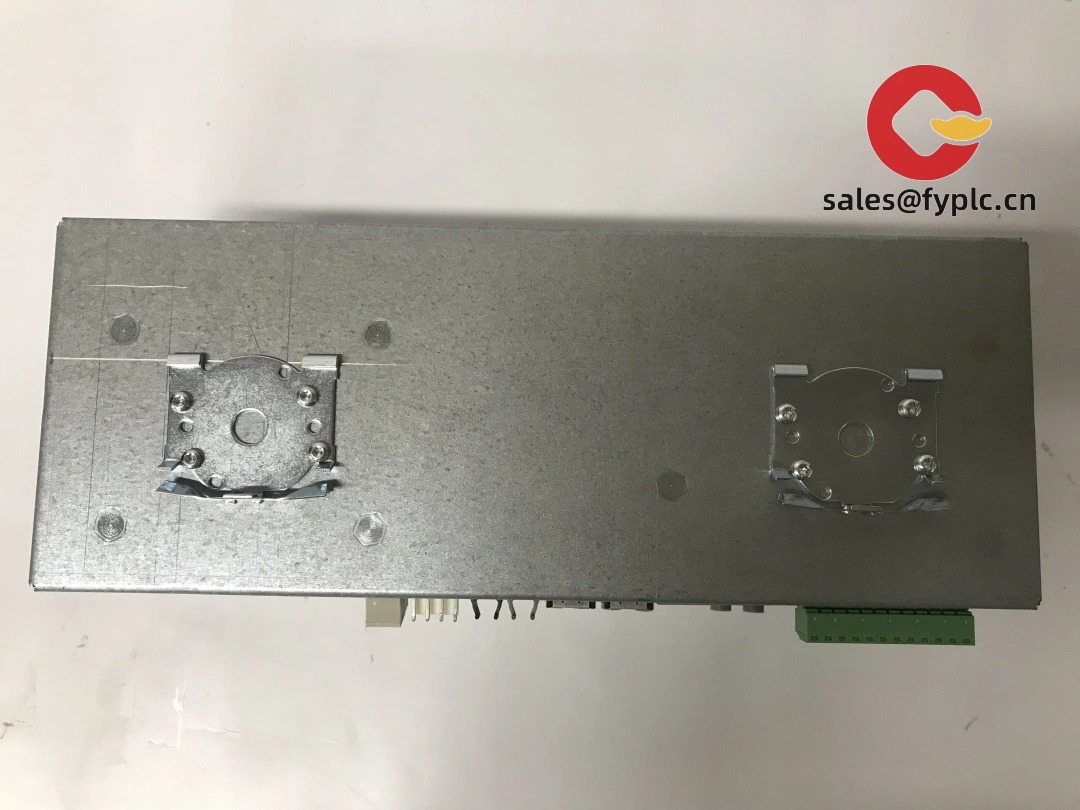

ABB NDCU-33CX 3AUA0000052751 – Control Unit for Industrial Automation Systems

If you’re upgrading or maintaining an ABB AC800M control system, the NDCU-33CX (3AUA0000052751) typically shows up as a reliable workhorse in distributed process automation setups. From my experience, it’s not flashy—but it delivers consistent performance where uptime and integration matter most.

Key Features

- Digital Control Interface: Manages communication between I/O modules and the main controller, particularly within redundant configurations. One thing I appreciate is how smoothly it integrates with existing Profibus DP-V1 networks.

- Hot-Swappable Design: Supports module replacement without shutting down the system—this seems to be especially valuable during planned maintenance windows in continuous-process environments like chemical plants.

- Diagnostics & Redundancy Support: Built-in status LEDs and error logging help reduce troubleshooting time. In many cases, users report faster fault isolation compared to older non-diagnostic units.

- ABB AC800M Compatibility: Specifically designed for use with ABB’s Symphony Plus and Extended Automation systems. You might notice that firmware alignment across the rack can make or break stability—so version matching matters.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / NDCU-33CX (3AUA0000052751) |

| HS Code | 85371090 |

| Power Requirements | Supplied via backplane (24 V DC typical) |

| Dimensions & Weight | Standard 19″ rack unit (approx. 40 mm width); ~300 g |

| Operating Temperature | 0°C to +60°C |

| Signal Input/Output Types | Digital I/O interface via terminal blocks; supports fail-safe signaling |

| Communication Interfaces | Profibus DP-V1, peer-to-peer module communication over backplane |

| Installation Method | DIN rail mountable within ABB MOD 30ML or equivalent control cabinet |

Application Fields

This unit tends to appear in power generation facilities, water treatment plants, and oil & gas processing stations—anywhere ABB’s AC800M platform is used for centralized logic control. It’s commonly deployed in turbine control panels and burner management systems where deterministic response times are critical. One refinery client mentioned they rely on its redundancy features during compressor startups, which makes sense given the high-stakes nature of those operations.

Advantages & Value

While newer controllers offer more processing headroom, the NDCU-33CX still holds value due to its deep compatibility with legacy infrastructure. Procurement teams often prefer it when minimizing engineering rework—especially during partial upgrades. It appears that spare availability has tightened slightly over the past year, so stocking a few units ahead of scheduled turnarounds could prevent unexpected downtime. Firmware consistency across modules also reduces field configuration errors, which saves both time and labor costs.

Installation & Maintenance

Mounting requires a standard ABB MOD 30ML base frame with proper grounding. Keep ventilation clear around the module—don’t stack equipment too tightly in the cabinet. Wiring should follow ABB’s recommended torque specs (typically 0.6 Nm) to avoid contact issues. From a maintenance standpoint, periodic visual checks of status LEDs and cleaning dust from heatsinks go a long way. Also, consider syncing firmware updates during plant outages, even if the change log seems minor. Some users have reported improved bus stability after applying the latest patch set.

Quality & Certifications

The NDCU-33CX carries CE, UL, and RoHS compliance marks, indicating adherence to major industrial safety and environmental standards. It’s built under ISO 9001-certified processes, which gives some confidence in batch consistency. The warranty period is 365 days from shipment—covering defects in materials and workmanship under normal operating conditions. No coverage is provided for damage caused by incorrect installation, ESD events, or unauthorized modifications.

Ordering Notes: Delivery takes about one week for in-stock units, though lead times can stretch to four weeks for backordered items. We require a 50% advance payment to confirm the order, with full balance due before shipment. All deliveries are handled via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.