Description

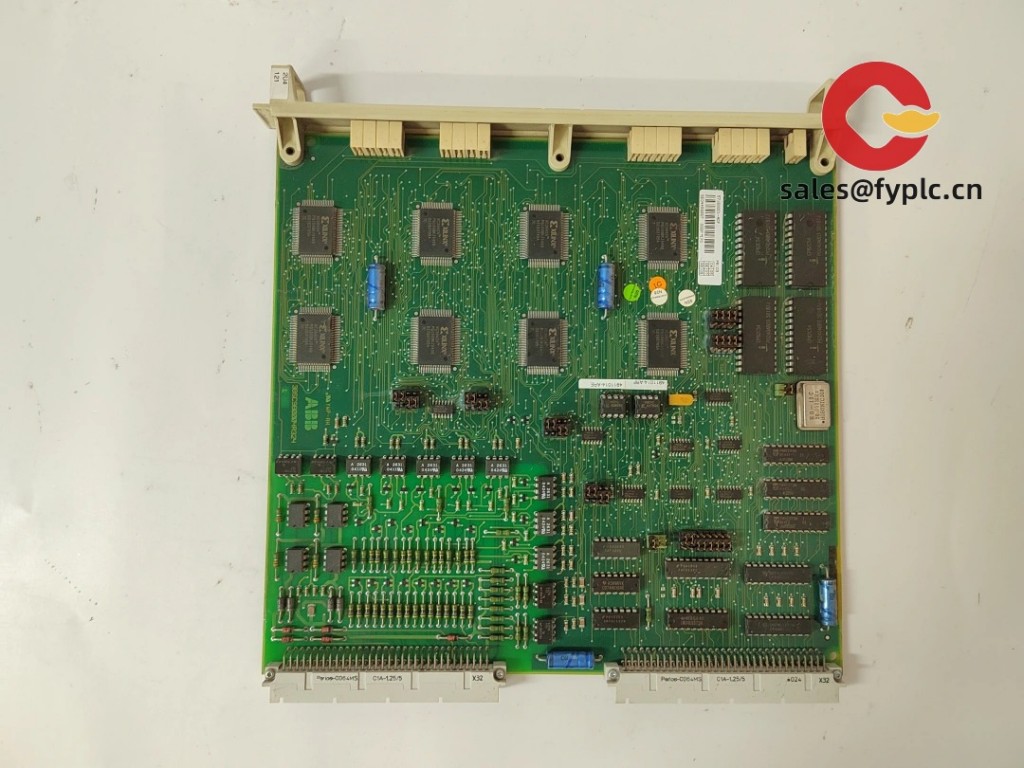

ABB DSQC545A 3HAB8101-19 – Robot Arm I/O and Communication Module

If you’re working with ABB IRB robot systems—especially in automotive or high-speed manufacturing—you’ve likely come across the DSQC545A module. The 3HAB8101-19 variant serves as a key I/O and communication interface for the robot controller, typically mounted in the IRC5 cabinet. One thing I appreciate is how it consolidates digital signals and fieldbus connectivity into a compact unit, reducing wiring complexity on the plant floor.

Key Features

- Digital I/O handling: Manages up to 32 digital inputs and 16 outputs, which makes it suitable for coordinating grippers, sensors, and safety interlocks directly through the robot logic.

- Fieldbus support: Includes DeviceNet interface for seamless integration with PLCs and peripheral devices—typically used when syncing robot motion with conveyor tracking or vision systems.

- Compact design: Designed for DIN-rail mounting inside standard IRC5 cabinets. Saves space compared to older multi-module setups.

- Hot-swappable: In most cases, replacement can be done without powering down the entire cell, minimizing unplanned downtime.

- Firmware traceability: Each unit carries a scanable barcode for version control, which helps during troubleshooting or system audits.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / DSQC545A (3HAB8101-19) |

| HS Code | 85371090 |

| Power Requirements | 24 VDC (supplied via backplane from IRC5) |

| Dimensions & Weight | Approx. 120 x 100 x 70 mm, ~300 g |

| Operating Temperature | 0°C to +55°C (industrial grade) |

| Signal I/O Types | 32 DI, 16 DO (24 VDC) |

| Communication Interfaces | DeviceNet master/slave, internal bus via PTP5 connector |

| Installation Method | DIN rail mount (TS35) in ABB IRC5 cabinet |

Application Fields

This module shows up most often in automotive body shops, where ABB robots handle spot welding or material transfer. From my experience, it’s also common in packaging lines using IRB 360 FlexPicker robots—especially when precise coordination with external conveyors is needed. You might notice that facilities upgrading legacy DSQC355A systems are switching to this model for better diagnostics and network resilience.

Advantages & Value

Procurement teams tend to favor this module because of its interchangeability across multiple ABB robot types. Spare inventory becomes simpler. Also, since it uses standard DeviceNet, there’s less dependency on proprietary cables or adapters. While not the cheapest I/O card out there, the mean time between failures (MTBF) seems to be well over five years in clean environments. That kind of reliability usually pays off in reduced maintenance labor and fewer production stops.

Installation & Maintenance

Mounting is straightforward—just snap it onto TS35 rail and connect the PTP5 backplane cable. Make sure the cabinet meets IP54 standards and has adequate ventilation, especially if ambient temps exceed 40°C. Avoid sharing power rails with high-noise equipment like contactors. For maintenance, visually inspect terminals every six months. Clean dust buildup with compressed air—don’t use solvents. Firmware updates are rare but should be applied during scheduled controller upgrades to maintain compatibility.

Quality & Certifications

The DSQC545A carries CE, UL, and RoHS compliance marks, and is built under ISO 9001-controlled processes at ABB facilities. Units we supply are either new surplus or factory-refurbished with full burn-in testing. Warranty is 365 days—covers defects in materials and workmanship, though not physical damage or incorrect installation.

Order Notes: Delivery within one week if in stock; otherwise, no more than four weeks. Payment: 50% advance, balance before shipment. Shipped via FedEx, UPS, or DHL.

Reviews

There are no reviews yet.