Description

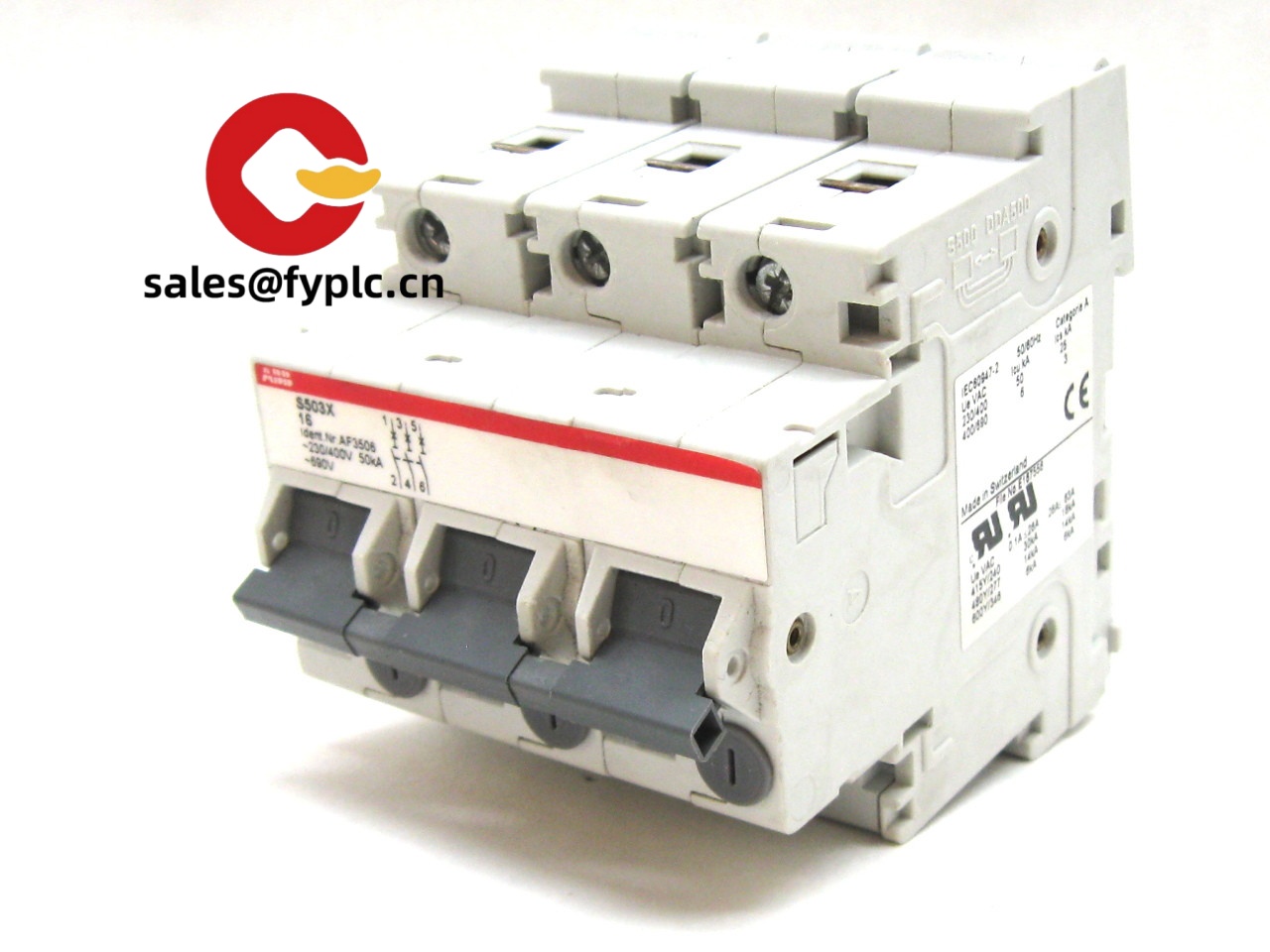

S503X – Compact Industrial Signal Conditioner for Reliable Process Control

You might notice that in high-noise environments—like chemical processing or motor control cabinets—signal drift and interference can quietly undermine system accuracy. The S503X seems to handle this well. It’s a DIN-rail mounted signal conditioner designed to isolate, convert, and transmit analog signals with solid stability across fluctuating conditions.

From my experience working with legacy PLC systems that lack built-in isolation, adding something like the S503X typically prevents ground loops and protects sensitive inputs. One thing I appreciate is how it handles multiple input types without requiring hardware changes—just configuration via DIP switches.

Key Features

- Universal Analog Input: Accepts voltage (0–10 V) and current (0/4–20 mA) signals without external shunts—configured locally.

- Galvanic Isolation: Separates input, output, and power circuits up to 3.75 kV AC, reducing noise coupling in electrically noisy plants.

- High Accuracy: ±0.1% full-scale deviation, which helps maintain consistency in batch processing or dosing applications.

- DIN-Rail Mounting: Fits standard 35 mm TS35 rails—commonly used in control panels—making retrofitting straightforward.

- LED Status Indicators: Real-time visual feedback on power and signal status, useful during commissioning or troubleshooting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / S503X |

| HS Code | 8537.10.90 (Control panels for industrial automation) |

| Power Requirements | 20–30 V DC or 18–28 V AC, ~25 mA typical draw |

| Dimensions & Weight | 110 × 22.5 × 110 mm (H×W×D), ~180 g |

| Operating Temperature | -20°C to +60°C (no condensation) |

| Signal Input Types | 0–10 V, 1–5 V, 0/4–20 mA (switch-selectable) |

| Signal Output Types | Isolated 0/4–20 mA or 0–10 V, configurable |

| Communication Interfaces | None (analog-only device) |

| Installation Method | Top-hat rail (35 mm DIN EN 60715) |

Application Fields

This unit shows up often in wastewater treatment plants where sensor signals from pH or level probes travel long distances into central controllers. It also appears in packaging lines using older HMIs that don’t support live diagnostics—here, the S503X acts as a clean interface between field devices and the control layer. In many cases, it’s used when upgrading systems incrementally and full digitalization isn’t feasible yet.

Advantages & Value

Procurement teams tend to favor the S503X because it avoids costly PLC upgrades just to add isolation. Its compatibility with most analog sensors means spare inventory is easier to manage. While not a smart device, its reliability in harsh electrical environments makes it a low-maintenance choice—especially in facilities where downtime costs outweigh feature richness.

Installation & Maintenance

Mount it on a clean, stable DIN rail inside an IP54-rated enclosure. Avoid placing near large contactors or VFDs unless separated by shielding plates. Wiring should use twisted-pair shielded cable, grounded at one end only. From what I’ve seen in panel audits, poor grounding causes more issues than the device itself.

Routine checks every six months—visual inspection, cleaning dust buildup, verifying output with a loop calibrator—typically keep it running smoothly. No firmware updates, of course, but checking calibration annually helps prevent subtle drift in critical processes.

Quality & Certifications

It carries CE marking under the EMC and Low Voltage Directives, and complies with RoHS requirements. Not UL listed, so avoid use in safety-critical U.S.-based installations unless enclosed in a certified assembly. The manufacturer offers a standard 365-day warranty against defects in materials and workmanship.

Ordering Notes: Delivery within one week if in stock; maximum lead time no more than one month. Payment requires 50% advance, balance before shipment. Shipped via FedEx, UPS, or DHL depending on destination.

Reviews

There are no reviews yet.