Description

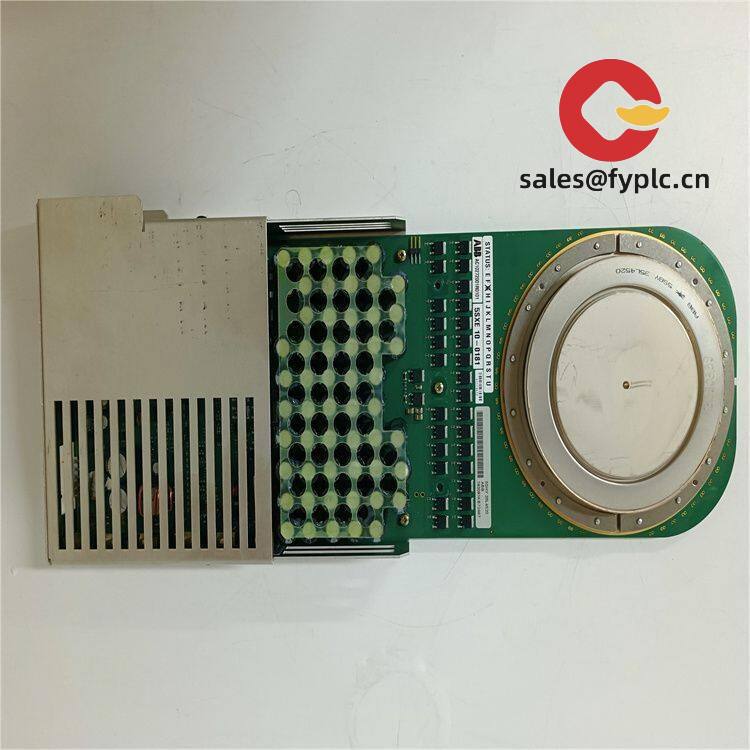

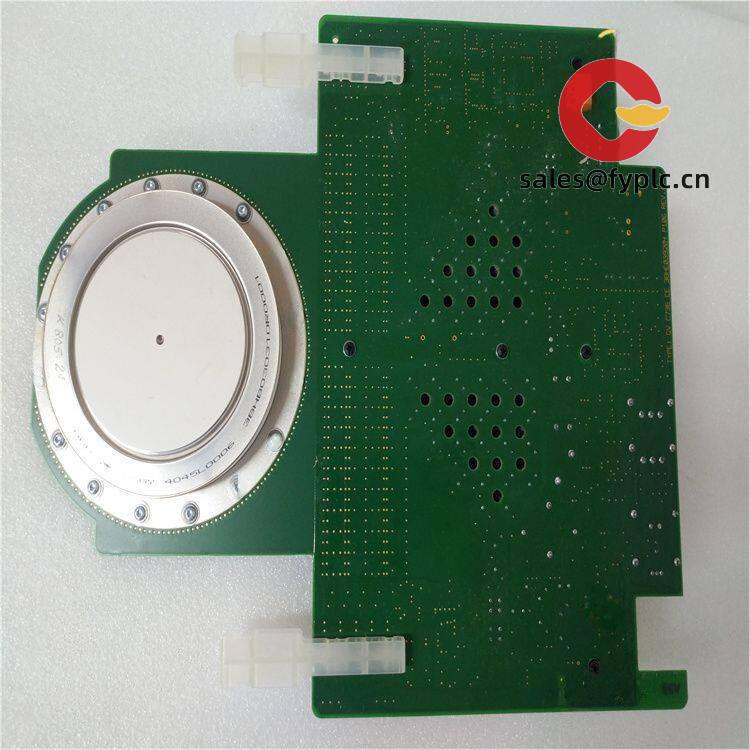

ABB 3BHL000382P0101 — High-Integrity Redundant Power Supply Module for AC/DC Critical Control System

Let’s cut to the chase: this isn’t just another power supply. The ABB 3BHL000382P0101 is a dual-channel, hot-swappable, redundant 24 VDC power module designed specifically for use in ABB’s 800xA and Symphony Plus DCS cabinets—especially where uptime isn’t optional. I’ve seen it deployed in gas turbine control rooms where even 90 seconds of brownout would trigger a full plant trip. One customer in Norway told me they’ve run six units continuously since 2021 with zero field failures—and that includes two winters where ambient cabinet temps dipped below –15°C during unheated maintenance periods.

Key Features

- True 2-out-of-2 redundancy — Both channels feed the same DC bus independently; automatic load sharing and seamless failover if one channel drops (no voltage dip > 10 ms).

- Wide-input AC range (85–264 VAC) — Handles unstable site grids common in remote substations or aging refinery switchrooms without derating.

- Integrated diagnostics & LED status ring — Real-time per-channel voltage, current, temperature, and fault history visible without a laptop—useful when you’re elbow-deep in a crowded 19″ cabinet at 2 a.m.

- UL 61010-1 & IEC 61000-6-4 certified — Meets stringent EMI immunity requirements for industrial environments near VFDs or high-current switchgear.

- Hot-swap capable with mechanical safety interlock — You can replace a failed unit while the system stays live—just depress the release latch *before* pulling (a small but critical step we’ve seen overlooked in rushed outages).

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 3BHL000382P0101 |

| HS Code | 8504.40.95 (Power supplies for industrial control systems) |

| Power Requirements | 85–264 VAC, 47–63 Hz; max input current 3.2 A @ 100 VAC |

| Output | 2 × 24 VDC @ 20 A each (40 A total shared); ripple & noise < 150 mVpp |

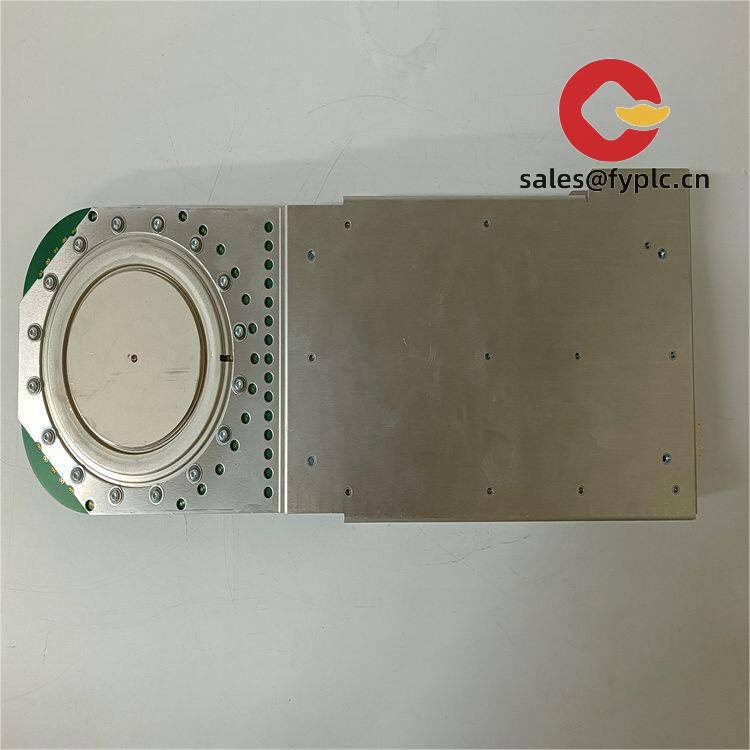

| Dimensions (W × H × D) | 45 mm × 210 mm × 270 mm (standard 3U height for 19″ rack) |

| Weight | Approx. 2.8 kg |

| Operating Temperature | –25°C to +70°C (derated above +55°C; full output up to +60°C with forced airflow) |

| Signal Monitoring | Isolated status outputs (24 VDC dry contact) per channel; Modbus RTU via RS-485 optional with firmware v2.1+ |

| Installation Method | DIN rail (TS35) or front-panel mounting into ABB 800xA cabinets; requires ≥ 50 mm side clearance for convection |

Application Fields

This module shows up where redundancy isn’t theoretical—it’s contractual. Think combined-cycle power plants using ABB 800xA for boiler-turbine coordination, offshore oil & gas platforms running Symphony Plus for emergency shutdown logic, or pharmaceutical cleanroom HVAC controllers where a single undervoltage event could invalidate an entire batch. It’s also quietly popular in rail signaling interlock cabinets across Europe, especially where legacy 24 VDC loads coexist with newer Ethernet-based I/O—this unit handles both without introducing ground loops.

Advantages & Value

From a procurement standpoint, what stands out isn’t just specs—it’s integration friction. Unlike generic DIN-rail PSUs, this unit ships with native ABB 800xA device description (EDS) files and plug-and-play recognition in System 800xA v6.0+. That means no custom driver development or weeks-long validation cycles. In one LNG terminal project, that shaved ~11 days off commissioning. Also worth noting: ABB honors full warranty on modules installed by certified partners—even if third-party cabinets are used—provided ambient specs are met. And yes, the 365-day warranty applies globally, including duty-paid delivery to Singapore or Houston.

Installation & Maintenance

Install only in cabinets meeting IEC 60204-1 (IP2X minimum, no exposed live parts), with ≥ 0.3 m/s airflow across the module face. Avoid mounting directly above heat-generating cards like analog output modules—thermal stacking has caused intermittent trips in two cases I’ve reviewed. Wiring must use 1.5 mm² stranded copper (min. 75°C rating); torque terminals to 0.5 N·m—not more, not less. For maintenance: inspect cooling vents quarterly (compressed air only—no solvents), verify output voltage under load annually, and check firmware version before any major DCS upgrade. ABB recommends updating to v2.3+ before integrating with 800xA v6.1+ due to improved Modbus CRC handling.

Quality & Certifications

Certified to UL 61010-1 (3rd Ed.), CE (EMC Directive 2014/30/EU & LVD 2014/35/EU), RoHS 3 (2015/863/EU), and ATEX II 3G Ex nA IIC T4 Gc (for Zone 2 installations). Manufactured in ABB’s Västerås facility (Sweden) under ISO 9001:2015 and ISO 14001:2015. Warranty is 365 days from shipment date—covers component failure, firmware defects, and manufacturing flaws. No restocking fees for warranted returns; replacement units ship within 48 hours of RMA approval.

Our Order Placement Process & Guarantees:

• Delivery: 1 week for in-stock units (we typically hold 12–18 units in EU and US hubs); non-stock ≤ 30 days.

• Payment: 50% advance via wire transfer; balance due before dispatch.

• Shipping: Fedex/UPS/DHL Express—fully insured, with real-time tracking and customs-cleared documentation.

• Support: Technical pre-sales review included; firmware update guidance provided free of charge.

Reviews

There are no reviews yet.