Description

ABB 5SHY40L4511 – High-Performance Thyristor for HVDC & Industrial Power Control

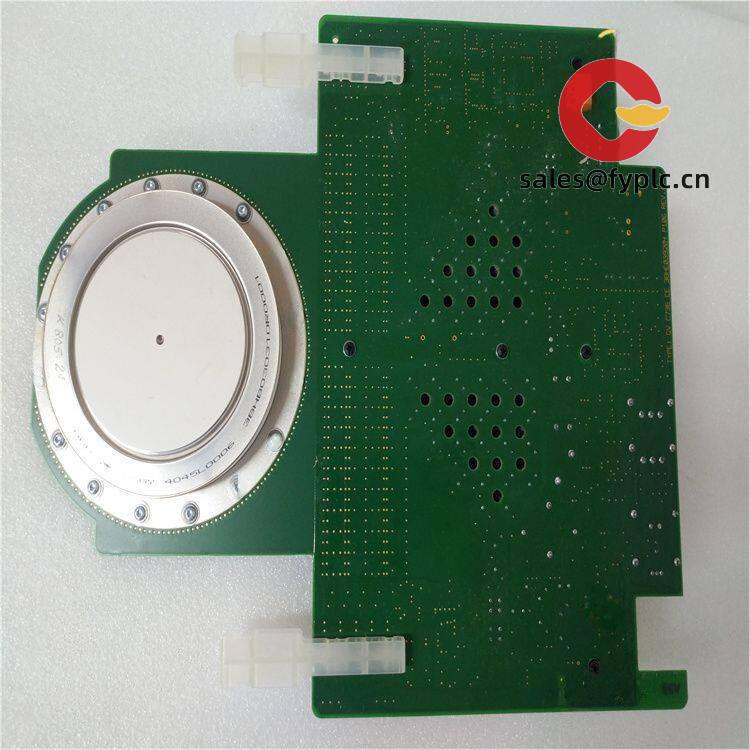

If you’re working on high-voltage DC transmission systems or heavy-duty industrial drives, the ABB 5SHY40L4511 is one of those components that tends to show up in reliable, long-life designs. It’s a press-pack thyristor—so no screws, no mechanical stress points—and built specifically for applications where thermal cycling and mechanical fatigue can take down lesser devices.

One thing I appreciate about this model is how it balances peak surge capability with stable average current handling. In many cases, engineers end up oversizing when they need both, but this unit holds up well under repeated 4000A surges while still managing a solid 1180A average current. That kind of headroom matters when you’re designing for arc furnaces or traction substations.

Key Features

- Press-Pack Design: Eliminates bolted connections, reducing contact resistance and improving thermal cycling endurance—typically used in stacked configurations within valve stacks.

- High Surge Current Rating: Handles up to 4000A (½ cycle, 60Hz), making it resilient during grid transients or motor startup surges.

- Reverse Voltage Withstand: Rated at 4500V, suitable for multi-level converters in HVDC stations and static VAR compensators.

- Low Forward Voltage Drop: Typically around 1.25V, which helps reduce conduction losses and cooling demands over time.

- Designed for Forced Air or Liquid Cooling: Flat ceramic housing ensures efficient heat transfer when mounted between heatsinks in a pressurized stack.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 5SHY40L4511 |

| HS Code | 8542.39.00 |

| Type | Thyristor (SCR), Press-Pack |

| Repetitive Peak Reverse Voltage (VRRM) | 4500 V |

| Repetitive Peak Off-State Voltage (VDRM) | 4500 V |

| Average On-State Current (ITAV) | 1180 A @ 180°C case temp |

| Surge Current (ITSM) | 4000 A (½ cycle, 60 Hz) |

| On-State Voltage Drop (VT) | ~1.25 V (typical at full load) |

| Gate Trigger Current (IGT) | 50 mA max |

| Installation Method | Press-fit between heatsinks, uniform pressure (~30 kN typical) |

| Operating Junction Temperature | -40°C to +125°C |

| Case Style | Ceramic Disc, Double-Sided Cooling |

Application Fields

The 5SHY40L4511 shows up most often in high-reliability environments. From my experience, it’s commonly found in HVDC valve halls—especially older ABB-built converter stations—where redundancy and mean time between failures are critical. It’s also used in large industrial rectifiers for aluminum smelting, rolling mill drives, and some static VAR compensation systems.

You might notice that some replacement orders come from European rail infrastructure projects. That makes sense—the device handles the kind of transient overloads seen in 16.7 Hz traction substations without flinching.

Advantages & Value

While newer IGCTs and IGBTs get more attention, there’s still real value in using proven thyristor technology like this—especially if your system already uses press-pack modules. Compatibility with existing clamping hardware and cooling plates means less re-engineering.

Procurement-wise, stocking these as spares tends to be cost-effective. Even though each unit isn’t cheap, avoiding unplanned downtime in a critical process usually justifies the investment. And since ABB maintains long-term availability for such parts, obsolescence risk seems lower than with some niche semiconductors.

Installation & Maintenance

Proper installation is non-negotiable. These units need even pressure distribution across the ceramic surface—uneven force leads to hot spots and premature failure. Most manufacturers recommend using a calibrated hydraulic press with parallel alignment, typically applying 28–32 kN depending on stack size.

Make sure the heatsink surfaces are flat (within 10 µm) and clean. Any debris or oxidation increases thermal resistance. Once installed, monitor coolant flow regularly if using liquid cooling. Also, consider periodic thermographic inspection during maintenance windows—it helps catch early signs of imbalance in parallel-connected strings.

Quality & Certifications

This thyristor carries standard ABB quality controls and meets IEC 60747-6 for semiconductor devices. While not always labeled individually, units conform to RoHS directives and are typically UL recognized for use in industrial equipment.

Each unit comes with full traceability, including batch number and test data upon request. The warranty period is 365 days from shipment—covering defects in materials and workmanship, assuming proper installation and operating conditions.

Ordering Notes

Delivery takes about one week for in-stock units, and no more than a month if we need to pull from regional warehouses. We require 50% advance payment, with the balance due before dispatch. Shipments go out via FedEx, UPS, or DHL based on destination and urgency.

For large-scale replacements or fleet maintenance programs, let us know upfront—we sometimes coordinate direct pallet shipments with ABB logistics partners to avoid handling damage.

Reviews

There are no reviews yet.