Description

ABB PP865 3BSE042236R1 – High-Performance I/O Communication Processor for Industrial Automation

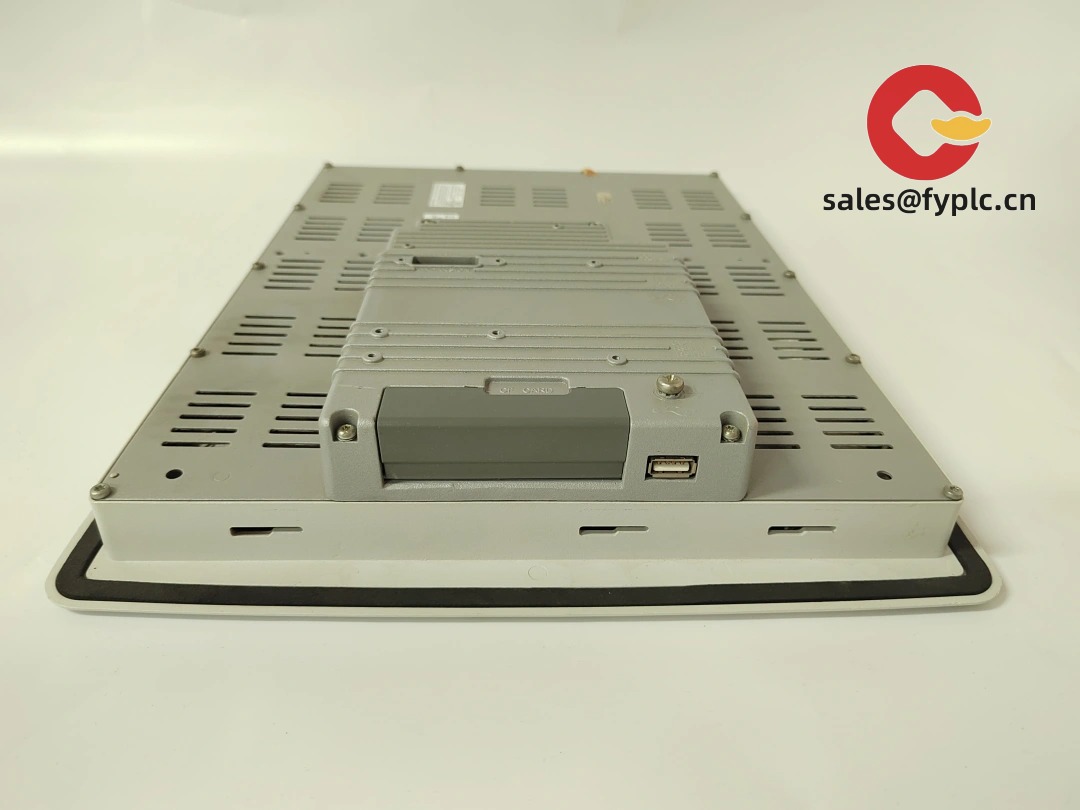

The ABB PP865 (model 3BSE042236R1) is a dedicated communication processor used in ABB’s Symphony Plus and Advant Master control systems. From my experience working with legacy DCS environments, this module tends to show up most often during system expansions or when replacing aging units in power plants and large-scale process facilities. One thing I appreciate is how it maintains backward compatibility while still supporting modern fieldbus integration—this can save engineering time during upgrades.

Key Features

- Robust communication handling: Manages data exchange between I/O modules and the main controller, typically over redundant MB+ (MasterBus Plus) networks. In many cases, this improves system resilience compared to point-to-point architectures.

- Hot-swappable design: You might notice that maintenance becomes less disruptive since the PP865 supports replacement without powering down the entire rack—provided redundancy is properly configured.

- Diagnostics and status monitoring: Integrated LED indicators make troubleshooting faster. Field feedback suggests engineers appreciate not having to pull logs just to confirm link activity.

- Backward compatible: Works seamlessly with older Advant OCS installations, which seems to be a big factor for sites avoiding full brownfield replacements.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BSE042236R1 (PP865) |

| HS Code | 85371090 |

| Power Requirements | Supplied via backplane (24 VDC typical) |

| Dimensions & Weight | Standard 19″ rack module (~120 x 150 x 30 mm), ~0.6 kg |

| Operating Temperature | 0°C to +55°C (with derating at higher temps) |

| Signal Input/Output Types | Digital communication interface only (no analog I/O) |

| Communication Interfaces | MB+ (MasterBus Plus), dual-channel for redundancy |

| Installation Method | DIN rail or 19” rack mount using adapter plate |

Application Fields

This processor is commonly found in heavy industrial settings where system uptime is critical. Think thermal power stations running ABB Symphony systems, oil & gas compressor stations, or chemical plants using legacy Advant OCS infrastructure. It’s not something you’d typically deploy in new greenfield projects—modern systems lean toward Ethernet-based controllers—but if you’re maintaining an existing ABB DCS setup, the PP865 remains a reliable workhorse.

Advantages & Value

Procurement teams tend to focus on availability and total cost of ownership. Since ABB no longer produces this unit in high volume, sourcing from trusted suppliers matters. Units we supply are tested and verified—not just pulled from surplus bins. That reduces commissioning delays. Also, because it integrates directly into existing racks without protocol gateways, there’s usually less engineering overhead than migrating to newer platforms. Some clients tell us they’re buying spares now “just in case,” which makes sense given lead times on obsolete parts can stretch into months.

Installation & Maintenance

Install in standard control cabinets meeting IP54 or better. Ensure adequate ventilation—especially in enclosed panels with multiple processors. Wiring should follow ABB’s guidelines for shielded twisted-pair cables on MB+ lines to avoid noise interference. Before hot-swapping, verify redundancy status through the control system HMI to prevent single-point failure. For maintenance, periodic visual inspection of connectors and cleaning dust filters (if applicable) helps longevity. Firmware updates aren’t typical—this isn’t a smart IoT device—but configuration backups are essential before any hardware changes.

Quality & Certifications

While the original unit was manufactured under ISO 9001 standards and carries CE marking, individual reconditioned units may vary in documentation. Each shipped module undergoes functional testing for link negotiation, power draw, and bus communication integrity. The warranty period is 365 days, covering defects in materials and workmanship under normal operating conditions.

Our Order Placement Process and Guarantees

Delivery takes about one week for in-stock units, with a maximum lead time of one month if coordination with partner warehouses is needed. We accept 50% advance payment, with full balance due before shipment. Express delivery via FedEx, UPS, or DHL ensures tracking and fast transit. If you’re planning a shutdown or retrofit, I’d suggest locking in spares early—these don’t get easier to find over time.

Reviews

There are no reviews yet.