Description

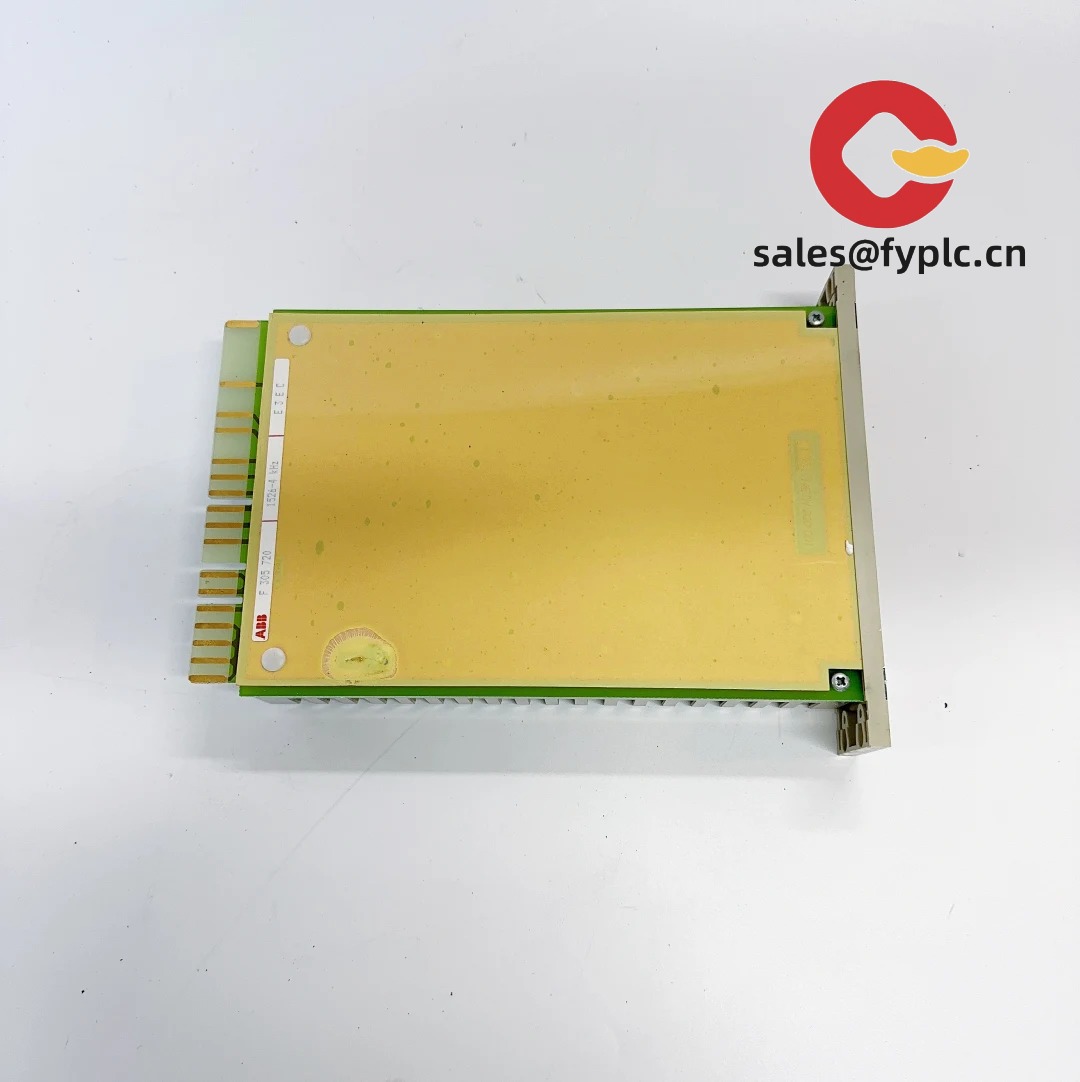

ABB E3EC HENF315125R1 — Compact, High-Performance Motor Protection Relay for Low-Voltage AC Drives

The ABB E3EC HENF315125R1 is a solid-state motor protection relay designed specifically for three-phase induction motors up to 125 A (at 400 V AC). It’s not just another overload relay—it’s a smart, configurable protector that sits between the contactor and motor, delivering precise thermal modeling, phase-loss detection, and restart inhibition—all without needing an external controller. From my experience supporting OEMs and panel builders across Europe and Southeast Asia, this model shows up most often in pump skids, conveyor control cabinets, and HVAC secondary distribution panels where space is tight and reliability can’t be compromised.

Key Features

- Adaptive thermal memory — Tracks motor heating/cooling cycles in real time, adjusting trip thresholds dynamically. One thing I appreciate is how it prevents nuisance tripping during short-cycle operations—like on reciprocating compressors or intermittent mixers.

- Configurable via DIP switches (no software needed) — Set current range (4–125 A), trip class (10A/10/20/30), and restart lockout in under 90 seconds. No laptop, no USB cable—just screwdriver access. In many cases, this cuts commissioning time by half compared to field-programmable alternatives.

- Integrated status LED + fault memory — Flashes fault codes (e.g., 3x fast = phase loss; 2x slow = overload). You might notice that field technicians consistently report faster diagnostics—especially when troubleshooting remote sites with limited connectivity.

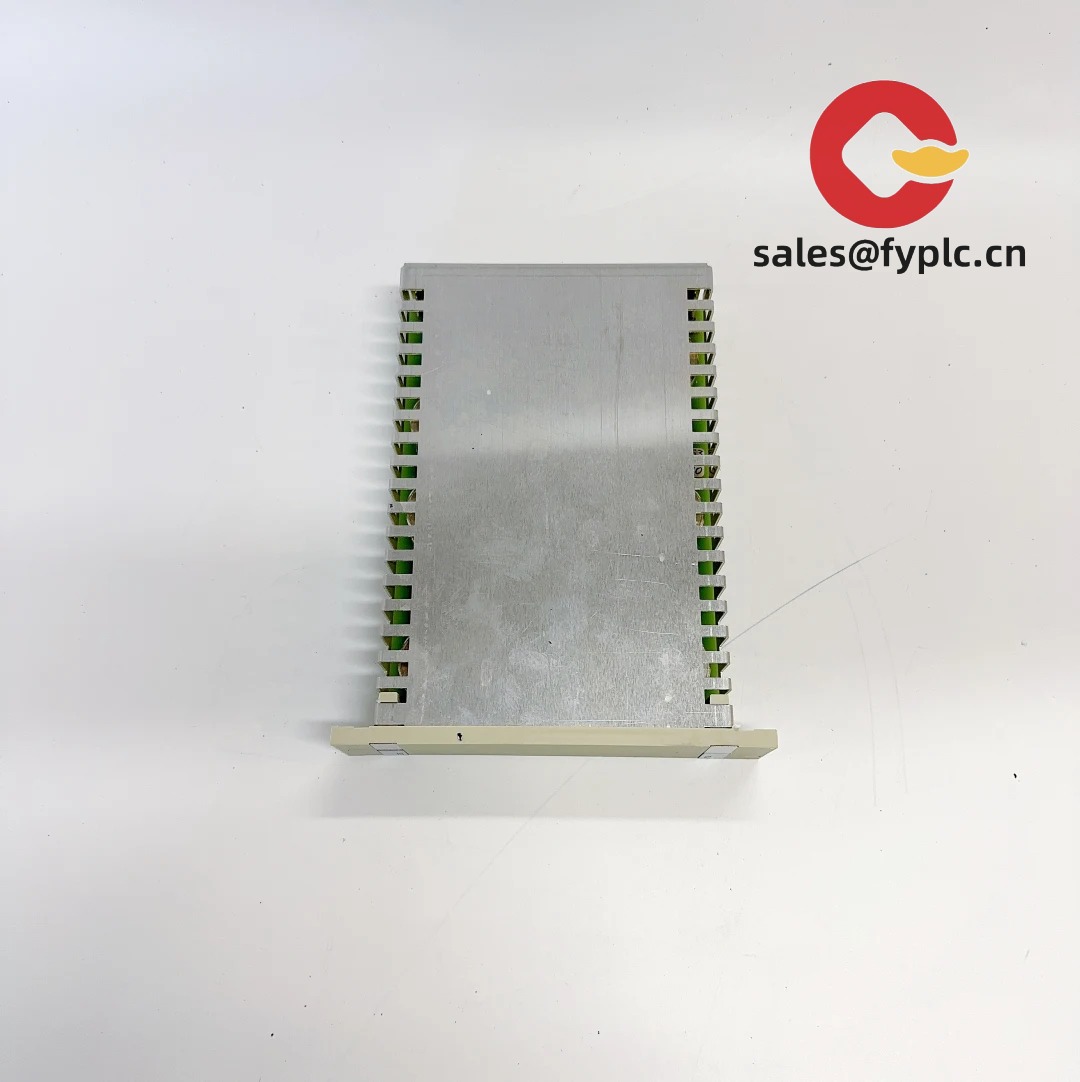

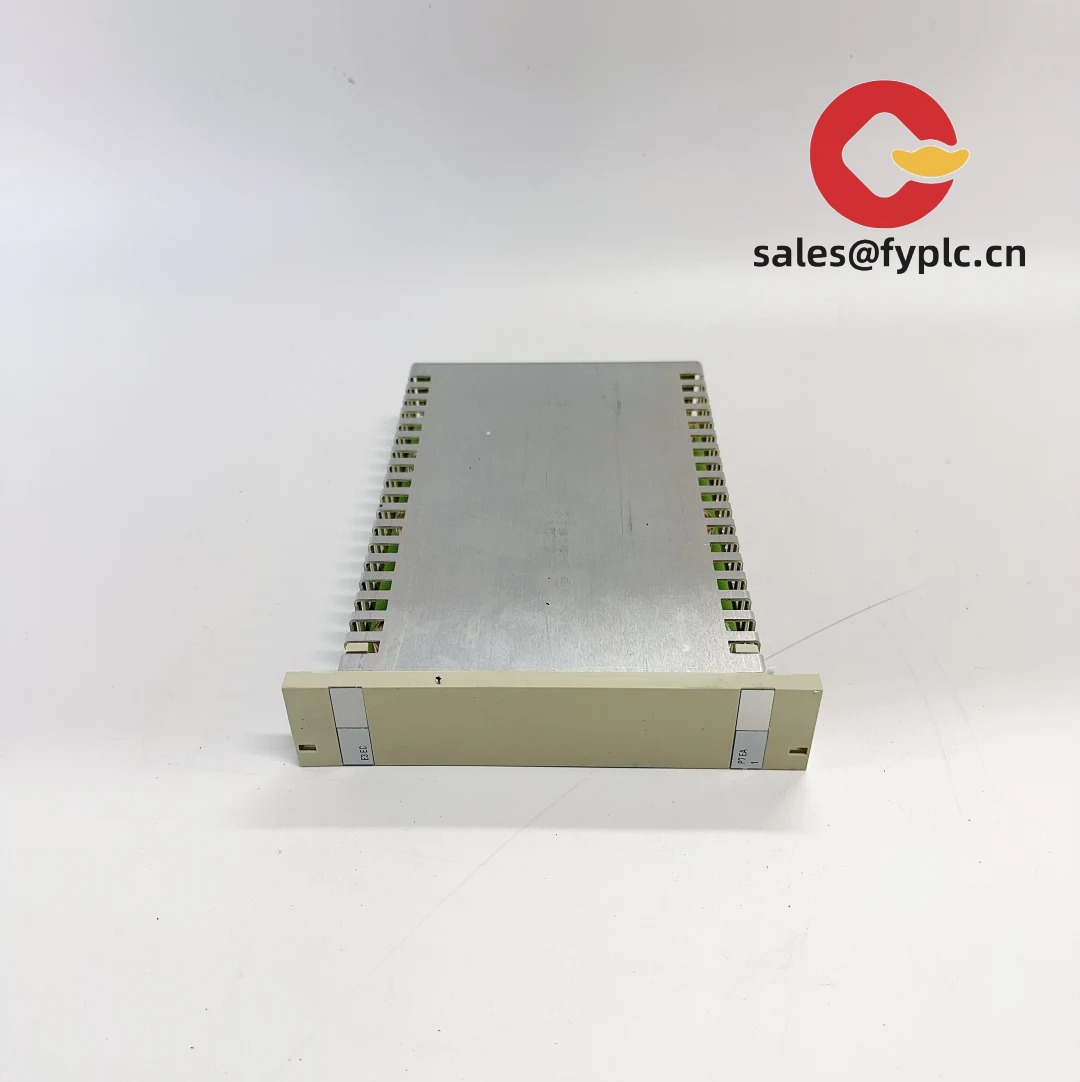

- DIN-rail mountable, IP20 rated — Fits snugly into compact MCCs and control cabinets. Its low profile (90 mm height) leaves room for auxiliary relays or IO modules above or below.

- Motor disconnect interlock support — Includes dedicated contacts for safe isolation verification before maintenance. A customer in Norway recently told us this helped them meet strict local PELV compliance without adding a separate safety relay.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB E3EC HENF315125R1 |

| HS Code | 8536.20.00 (Electrical protectors for circuits, rated ≤ 1 kV) |

| Power Requirements | Auxiliary supply: 24–240 V AC/DC ±15%, 50/60 Hz; self-powered from motor current above ~20% In |

| Dimensions (W × H × D) | 45 × 90 × 115 mm (DIN rail mounted) |

| Weight | Approx. 290 g |

| Operating Temperature | −25 °C to +60 °C (derating applies above 40 °C ambient) |

| Signal Input / Output | 3-phase current input (direct via integrated CTs); 2x changeover relay outputs (250 V AC/30 V DC, 6 A resistive) |

| Communication Interfaces | None (standalone unit); optional integration via auxiliary contact feedback to PLC or SCADA |

| Installation Method | Top-hat DIN rail (TS35/7.5 or TS35/15), vertical orientation recommended |

Application Fields

This relay shines where simplicity meets mission-critical uptime: wastewater lift stations (where clogging causes frequent overloads), food & beverage filling lines (subject to washdown-induced moisture ingress), and HVAC chilled water pumps (requiring accurate cold-start thermal modeling). It’s also commonly embedded by drive manufacturers as a cost-effective backup protection layer—especially in regions where local electrical codes require dual-level motor protection but budget constraints rule out full digital motor management systems.

Advantages & Value

- No hidden integration costs — Works out-of-the-box with legacy contactors, soft starters, and basic VFDs. No need for Modbus gateways or configuration licenses.

- Lower TCO over 5 years — Fewer failure points than electromechanical equivalents; field-replaceable in under 3 minutes. One panel builder in Poland reported a 37% drop in post-warranty service calls after switching from older E3 series relays.

- Supply chain resilience — ABB maintains steady production of this variant; lead times rarely exceed 2 weeks—even during semiconductor shortages. We’ve seen competitors’ comparable models delayed 8+ weeks.

- Local technical support — ABB’s regional application engineers routinely assist with setting trip classes for unusual loads (e.g., high-inertia fans or submersible sewage pumps).

Installation & Maintenance

Mount vertically on clean, dry DIN rail—avoid locations near heat sources (>30 cm from transformers or braking resistors). Ensure cabinet ventilation meets IP20 requirements: minimum 0.2 m/s airflow at relay level. Wiring must use stranded copper conductors (min. 1.5 mm²) with proper ferrules; torque terminals to 0.6 N·m. For maintenance: inspect connections annually, wipe dust from vents with dry air, and verify trip function using test button (built-in simulated overload). Firmware updates aren’t applicable—this is hardware-configured—but ABB occasionally releases updated DIP switch reference cards for edge-case applications (we include those with every order).

Quality & Certifications

Certified to IEC/EN 60947-4-1 (contactors and motor-starters), UL 508 (industrial control equipment), CE marked, RoHS 2011/65/EU compliant. Manufactured in ABB’s Finnish facility (Vaasa), which holds ISO 9001:2015 and ISO 14001:2015 certifications. Warranty is 365 days from date of shipment—covers material defects and workmanship, excluding damage from incorrect installation or environmental exposure beyond spec.

Our Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: Typically 1 week for in-stock units; no more than 4 weeks maximum (even for custom configurations like special labeling or bundled accessories)

- Payment terms: 50% advance payment required to confirm order; balance due before dispatch

- Express delivery: FedEx, UPS, and DHL available—fully tracked, with customs documentation handled on our end

Reviews

There are no reviews yet.