Description

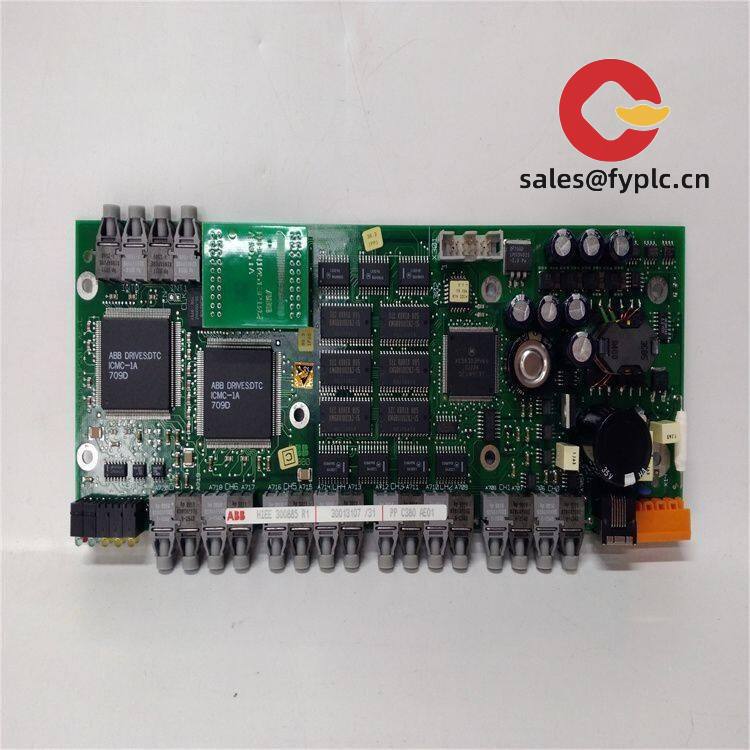

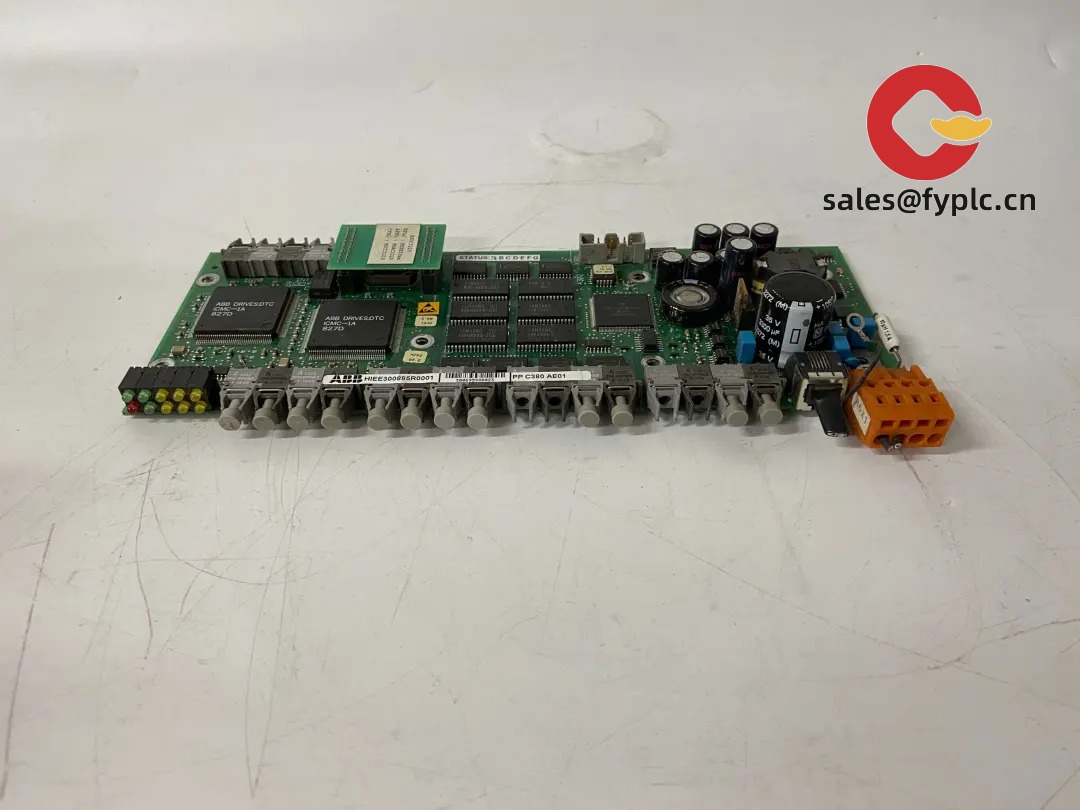

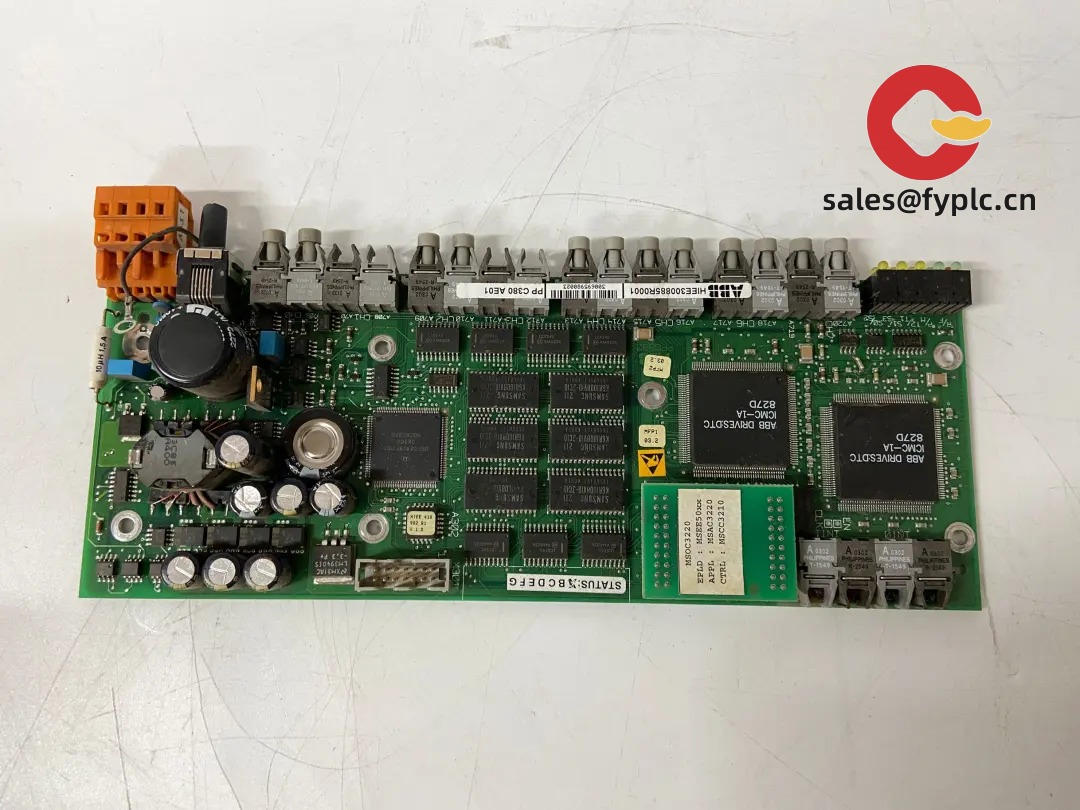

ABB HIEE300885R0001 – High-Performance Redundant CPU for Industrial Process Control

You might notice that in critical process environments—like power generation or oil & gas—the last thing you want is a controller failure bringing operations to a halt. That’s where the ABB HIEE300885R0001 comes into play. It’s not just another CPU module; it’s the core of ABB’s Symphony Plus S+ system, designed specifically for high-availability applications requiring seamless redundancy and real-time control.

From my experience working with distributed control systems (DCS), modules like this one typically make the difference between scheduled maintenance and unplanned downtime. The HIEE300885R0001 serves as a redundant main processor, meaning there’s always a backup ready to take over within milliseconds if the primary fails. In many cases, operators don’t even realize a switchover occurred.

Key Features

- Redundant Architecture: Dual CPUs operate in hot-standby mode, ensuring continuous process control without interruption during failures or firmware updates.

- Symphony Plus Integration: Native compatibility with ABB’s S+ ecosystem simplifies engineering, diagnostics, and integration with I/O modules and operator stations.

- High-Speed Processing: Handles complex regulatory and sequence logic efficiently, which seems crucial for turbine control or boiler management systems.

- Integrated Diagnostics: Real-time health monitoring helps predict potential issues before they escalate—something maintenance teams tend to appreciate during audits.

- Secure Communication: Supports standard industrial protocols with secure data exchange across the control network, reducing vulnerability risks.

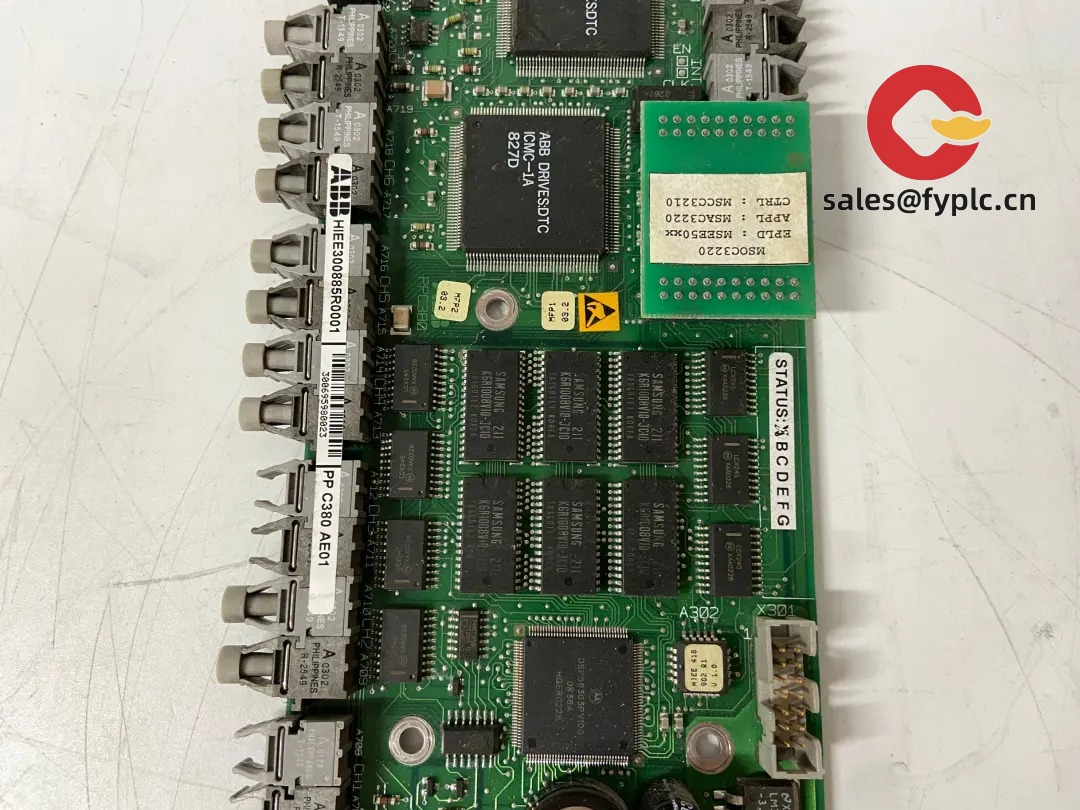

Technical Specifications

| Brand / Model | ABB / HIEE300885R0001 |

| HS Code | 85371090 |

| Power Requirements | 24 V DC nominal (range: 19.2–30 V DC) |

| Dimensions & Weight | Approx. 400 mm (W) × 250 mm (H) × 120 mm (D), ~3.2 kg |

| Operating Temperature | 0°C to +50°C (with derating above 40°C) |

| Signal Input/Output Types | Digital and analog signals via connected I/O modules (e.g., HIOE, HIPA series) |

| Communication Interfaces | Ethernet (Redundant LAN), Modbus TCP, OPC UA, IEC 61850 (optional) |

| Installation Method | DIN-rail mounted in standard 19” rack cabinet (part of Symphony Plus chassis assembly) |

Application Fields

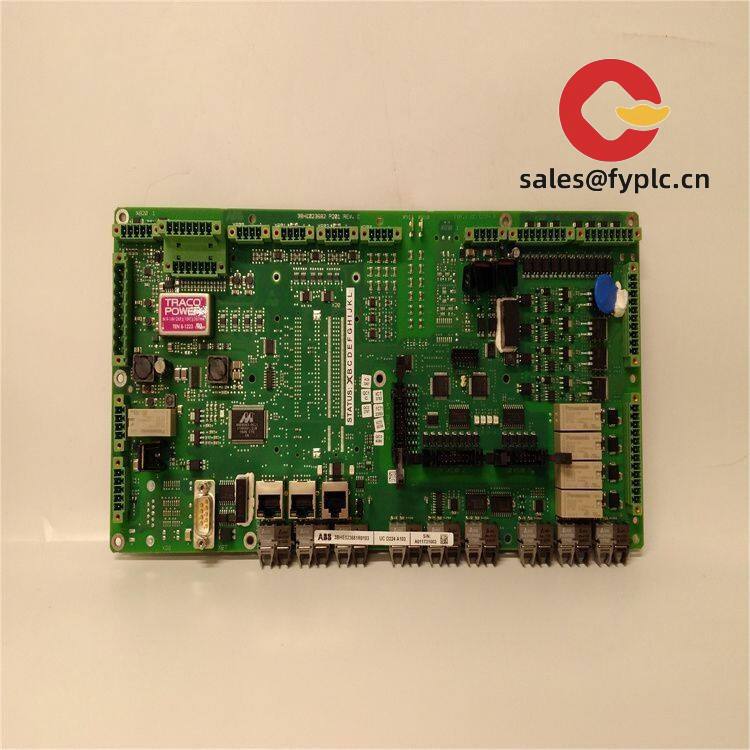

This module is commonly found in medium-to-large-scale industrial plants where uptime is non-negotiable. Think thermal power stations relying on precise burner management, refineries managing distillation columns, or water treatment facilities needing fail-safe pump sequencing. One thing I appreciate is how well it handles cascaded control loops in steam turbines—its deterministic response time keeps everything stable under load swings.

It also shows up in newer retrofits where legacy ABB Advant controllers are being phased out in favor of S+. Users have told me the migration path feels smoother because the programming environment (ABB Freelance or Symphony Plus Engineer) retains familiar logic structures while offering better diagnostics.

Advantages & Value

Procurement teams usually look beyond sticker price when evaluating these kinds of components. Reliability here translates directly into reduced OPEX—fewer emergency calls, less production loss. Since this unit supports online firmware upgrades and configuration changes, you can patch vulnerabilities or improve performance without shutting down.

Another subtle benefit? Compatibility. If your site already uses other ABB S+ hardware, adding this CPU avoids integration headaches. No protocol gateways, no middleware layers. And from a lifecycle standpoint, ABB tends to support these modules for 10+ years, which matters when planning long-term asset strategies.

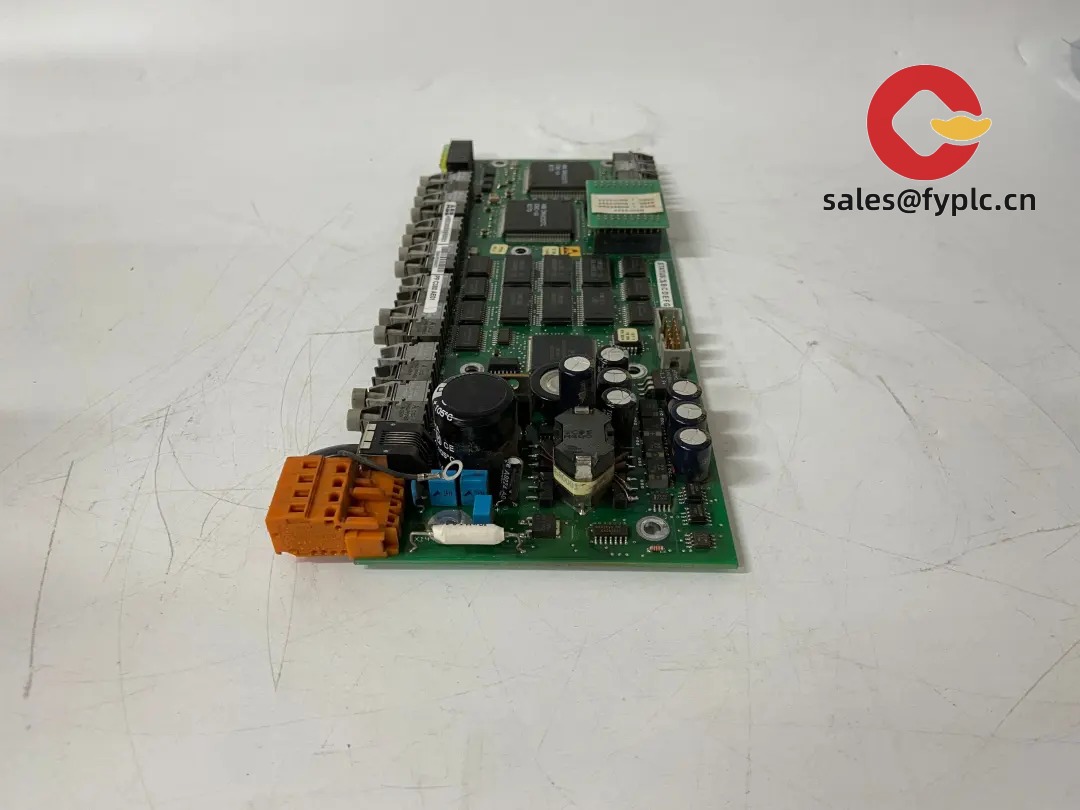

Installation & Maintenance

Make sure the control cabinet meets IP54 standards at minimum, especially in dusty or humid areas. Ventilation should allow free airflow around the module—don’t stack equipment too tightly. When wiring, use shielded twisted-pair cables for communication links and ground them properly at one end only to avoid ground loops.

Safety-wise, de-energize the rack before inserting or removing the CPU, even though it supports hot-swap in redundancy setups. On the maintenance side, schedule quarterly checks: clean air filters, verify sync status between redundant units, and review diagnostic logs. Firmware updates are recommended every 18–24 months unless security patches require earlier action.

Quality & Certifications

The HIEE300885R0001 carries CE, UL, and CSA certifications, confirming compliance with international industrial safety and EMC standards. It’s also RoHS compliant, so no restricted substances were used in manufacturing. Each unit undergoes burn-in testing before shipment, which typically catches infant mortality failures early.

We offer a full 365-day warranty against defects in materials and workmanship. Delivery takes about one week for in-stock units, and never more than a month. Payment terms are 50% upfront, balance before dispatch. We ship globally via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.