Description

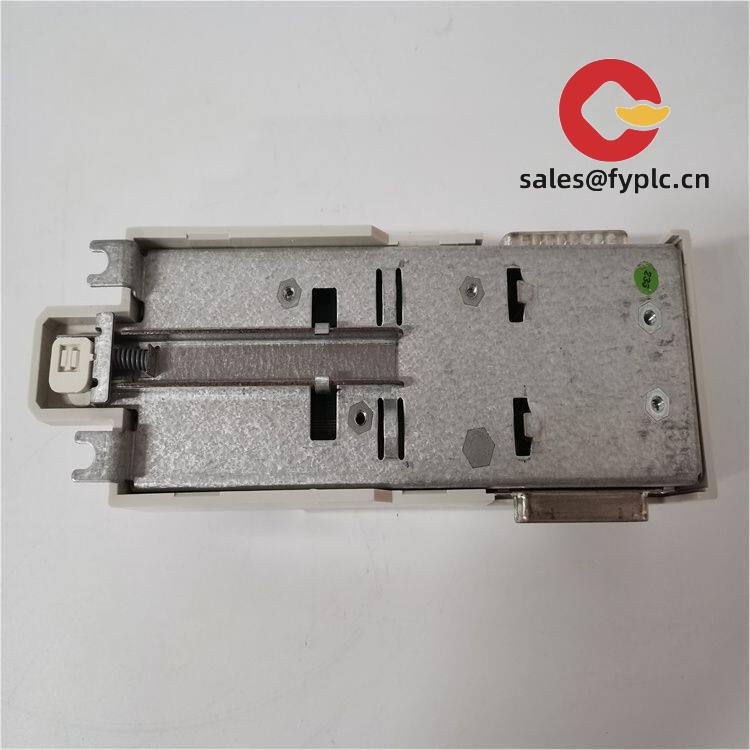

ABB 3BSE018126R1 – High-Performance AC Motor Drive Module for Industrial Automatio

If you’re working on a retrofit or maintenance project in process automation, the ABB 3BSE018126R1 typically shows up as a reliable choice for drive control in demanding environments. From my experience, it’s commonly used in legacy ACS600 and ACS800 drive systems—especially when uptime and compatibility matter. One thing I appreciate is how it integrates smoothly into existing cabinets without requiring major rewiring, which helps reduce commissioning time.

Key Features

- Digital Drive Interface: Serves as a control unit in ABB’s modular drive architecture, handling signal processing and communication between the operator interface and power components.

- Integrated Diagnostics: Built-in fault logging and status indicators help speed up troubleshooting—useful during unplanned outages.

- Fieldbus Ready: Supports common protocols like DCS, RS-485, and internal fiber-optic links to gate drives, making it adaptable in multi-drive setups.

- Backward Compatibility: Seems to be a go-to replacement for older ACS600 systems still running in pulp & paper, water treatment, and mining sectors.

- Firmware Flexibility: Can be updated via service tools, though caution is advised—mismatched versions sometimes cause boot issues.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BSE018126R1 |

| HS Code | 85371090 |

| Power Requirements | Powered via backplane from main drive cabinet (typically 24 V DC control supply) |

| Dimensions & Weight | Approx. 200 x 150 x 50 mm, 0.8 kg |

| Operating Temperature | 0 °C to +50 °C (with derating above 40 °C) |

| Signal Input/Output Types | Digital I/O for start/stop, fault feedback, analog inputs for reference signals |

| Communication Interfaces | Fiber-optic link to gate unit, RS-485 for fieldbus, DCS port for external control |

| Installation Method | DIN rail or panel mount within IP20-rated drive cabinet |

Application Fields

You might notice that this module pops up frequently in older but still-operational ABB drive systems across industries where motor control precision matters. In many cases, it’s found in large HVAC systems, conveyor drives in manufacturing, and pump arrays in municipal water plants. It’s not uncommon to see it in steel rolling mills too—especially where variable torque and tight speed regulation are needed.

Advantages & Value

While newer drives offer more connectivity, the 3BSE018126R1 holds value due to its availability and proven track record. For procurement teams, sourcing a functional unit can delay costly upgrades—especially when budgets are tight. It appears that most failures stem from power surges or aging capacitors, not design flaws, so a tested replacement often restores full operation. Plus, if your team already knows the platform, training costs stay low.

Installation & Maintenance

Make sure the cabinet meets IP20 standards and has adequate ventilation—this board doesn’t handle dust or condensation well. Before plugging it in, verify that the backplane is clean and undamaged. Static discharge is a real concern, so ground yourself first. On the maintenance side, periodic visual inspection helps catch corrosion early. Firmware updates should only be done with official ABB tools, and ideally during planned downtime. Some users report success with cleaning contact points using electronic-grade spray, but it’s a delicate process.

Quality & Certifications

The unit carries CE, UL, and RoHS compliance markings—standard for industrial electronics of this class. It’s manufactured under ISO 9001 guidelines, which gives some confidence in consistency. Each unit we ship comes with a 365-day warranty, covering defects in materials and workmanship. That’s particularly useful given that used or refurbished modules sometimes surface in the market with unknown service history.

Our Order Placement Process and Guarantees

Most in-stock units ship within one week. For harder-to-find models, delivery won’t exceed one month. We require a 50% advance payment to confirm the order, with the balance due before shipment. All deliveries are handled via FedEx, UPS, or DHL for tracking and reliability. If you’re replacing a live system, let us know—we can provide basic configuration notes upon request.

Reviews

There are no reviews yet.