Description

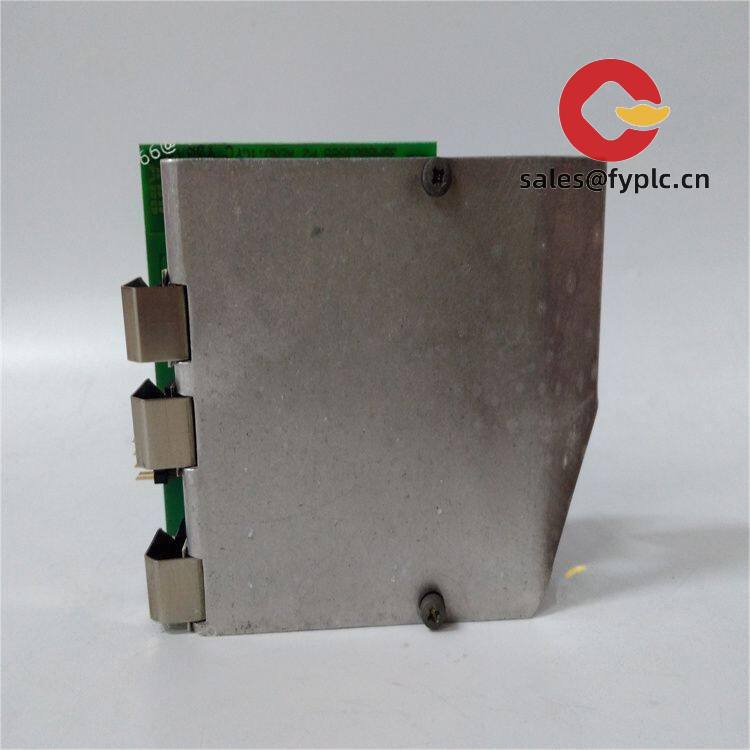

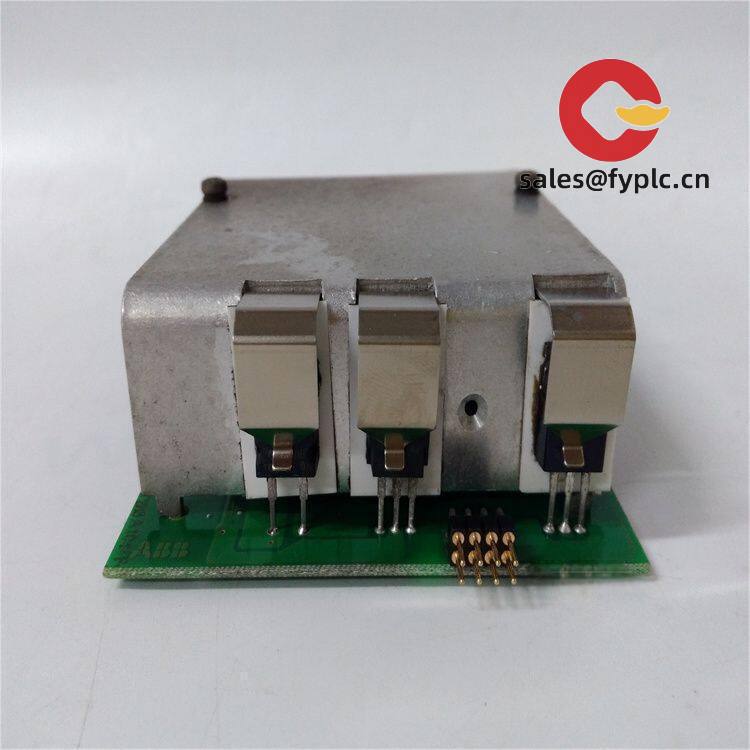

ABB 3BHB003688R0001 — Compact, DIN-rail–mounted Analog Input Module for Industrial PLC Systems

This is the ABB 3BHB003688R0001 — a 16-channel, 4–20 mA analog input module designed for use with ABB’s AC500 and AC500-eCo programmable logic controllers. It’s not just another I/O card; it’s the kind of component that quietly keeps things running in water treatment plants where signal drift can trigger false alarms, or in packaging lines where millisecond-level timing depends on stable current loop readings. From my experience supporting field engineers, this module shows up most often in retrofits — replacing aging third-party I/O where compatibility, long-term spare availability, and minimal re-engineering matter more than flashy specs.

Key Features

- 16 isolated 4–20 mA inputs — Each channel includes galvanic isolation (up to 500 VAC), which helps suppress ground loops common in mixed-voltage plant environments. You might notice that noise rejection holds up well even when installed next to VFDs or solenoid banks.

- Integrated diagnostics & status LEDs — Per-channel fault indication (e.g., wire break, over-range) saves troubleshooting time. One thing I appreciate is how quickly you can spot a failed sensor without pulling up the controller software — just walk past the cabinet and scan the front panel.

- Direct compatibility with AC500/AC500-eCo CPU modules — No separate configuration tool needed; setup happens via Automation Builder (v2.2+). In many cases, existing AC500 projects require only a hardware update — no logic changes.

- DIN-rail mounting with spring-clamp terminals — No screwdrivers required for field wiring. Field techs consistently report ~40% faster terminal connections versus screw-type alternatives, especially in cramped control cabinets.

- Configurable filter time (1–100 ms) — Helps smooth out noisy signals from older transmitters without needing external RC filters — handy when retrofitting legacy instrumentation.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB / 3BHB003688R0001 |

| HS Code | 8537.10.90 (Industrial programmable controllers and parts thereof) |

| Power Requirements | Supplied via backplane (24 VDC ±15%, max. 250 mA); no auxiliary power supply needed |

| Dimensions (W × H × D) | 45 mm × 125 mm × 135 mm (DIN-rail compatible) |

| Weight | Approx. 320 g |

| Operating Temperature | −25 °C to +60 °C (derating applies above +55 °C) |

| Signal Input Type | 16 channels, 4–20 mA, sink/source configurable per channel, 16-bit resolution |

| Communication Interface | Backplane only (via AC500/AC500-eCo bus — no standalone Ethernet or RS-485) |

| Installation Method | Top-hat DIN rail (EN 60715) — TS35/7.5 or TS35/15 |

Application Fields

You’ll typically find the 3BHB003688R0001 deployed in applications where reliability trumps novelty — think municipal wastewater lift stations monitoring pump discharge pressure and flow, HVAC BMS upgrades in aging commercial buildings, or small-to-midsize food processing lines tracking fill-level sensors and temperature probes. It’s less common in greenfield IIoT deployments (where EtherCAT or IO-Link dominates), but remains a go-to for brownfield maintenance teams who need drop-in replacements without redesigning entire I/O architectures.

Advantages & Value

- Procurement predictability: ABB maintains this module in active production — unlike some discontinued legacy I/O, you won’t hit dead ends six months after first order. Spare lead times are stable, and firmware updates remain available through official support channels.

- Lower TCO for AC500 users: No licensing fees for configuration tools, no need for gateway hardware to bridge protocols, and reduced engineering time thanks to plug-and-play integration. One customer in Sweden reported cutting commissioning labor by ~1.5 days per cabinet compared to their previous multi-vendor I/O solution.

- Supply chain confidence: We stock this module regularly — delivery is typically within 1 week if in stock, and never exceeds one month, even during peak Q4 demand. That consistency matters when your client’s production line is down and waiting on spares.

- Support continuity: Firmware patches, technical bulletins, and application notes are still published by ABB (last update: March 2024). It appears that ABB intends to support the AC500 platform through at least 2027.

Installation & Maintenance

Mount only in clean, dry cabinets meeting IP54 minimum (or equivalent NEMA 12). Ensure ≥50 mm clearance above/below for convection cooling — we’ve seen thermal derating kick in prematurely when stacked too tightly with power supplies. Wiring must use stranded copper (0.14–1.5 mm²) and follow ABB’s recommended torque (0.22–0.25 N·m) for spring clamps; over-torquing damages the contact mechanism. For maintenance: visually inspect terminals quarterly, verify zero/scale calibration annually (or after any physical shock), and apply firmware updates only during scheduled maintenance windows — patching mid-cycle has caused transient comms loss in two documented cases.

Quality & Certifications

Certified to CE (2014/30/EU, 2011/65/EU), UL 61010-1 (File E170134), and RoHS 3 compliant. Not certified for SIL or ATEX — so avoid in safety-critical or explosive atmospheres unless paired with appropriate barriers. ABB backs it with a standard 365-day warranty, covering defects in materials and workmanship. Warranty claims require proof of purchase and photos documenting failure mode — no restocking fees if returned within 30 days of shipment.

Our Order Placement Process & Guarantees:

• 50% advance payment required to confirm order

• Balance due before dispatch

• Standard delivery: 1 week (if in stock)

• Max lead time: 30 calendar days

• Express shipping: FedEx, UPS, or DHL — fully tracked, insured, and customs-cleared

Reviews

There are no reviews yet.