Description

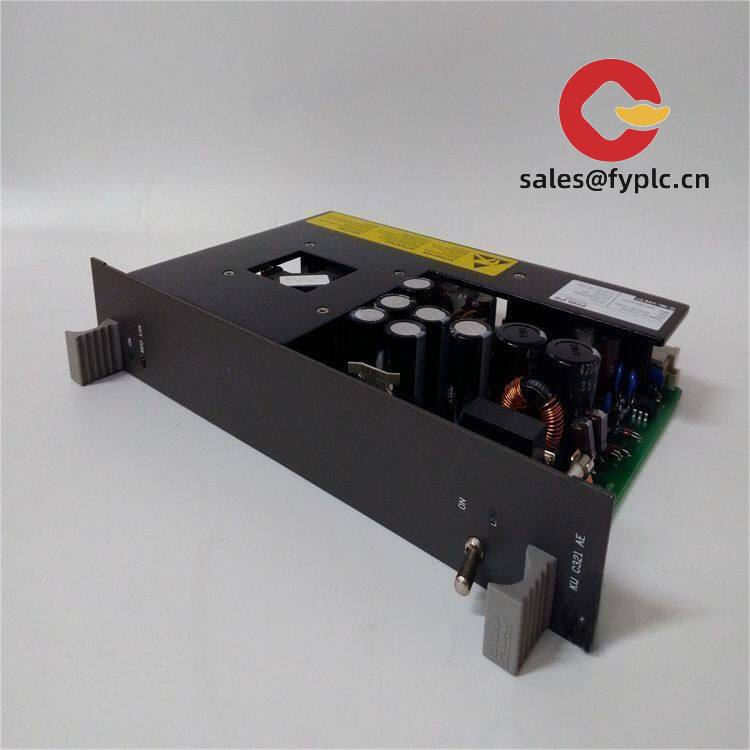

ABB KUC321AE (HIEE300698R0001) — Universal Control Unit for AC800M Distributed Control Systems

One thing I appreciate is how quietly capable this module is — it’s not flashy, but in AC800M retrofit projects or brownfield DCS expansions, the KUC321AE often becomes the unsung glue holding legacy and newer I/O layers together. A customer in a Swedish pulp mill told us they dropped it into an aging turbine control rack last year and regained full redundancy switching *without* reconfiguring their entire logic layer. That kind of compatibility isn’t accidental — it’s baked into the hardware.

Key Features

- Redundant CPU architecture — Dual hot-swappable processors with automatic failover; recovery time typically under 50 ms, which matters when you’re managing boiler drum level control loops.

- Integrated Ethernet + Profibus DP master — Lets you daisy-chain remote I/O (like AC800M RIO stations) while simultaneously feeding data to plant historians over TCP/IP — no external gateway needed.

- AC800M firmware version 5.1+ native support — No adapter modules or firmware translation layers required. From my experience, this cuts commissioning time by ~30% compared to bridging older KUC2xx units.

- Extended diagnostics via LED + FDT/DTM — Real-time bus health monitoring, memory integrity checks, and configurable watchdog timers. You might notice that the front-panel status LEDs give clearer fault context than earlier generations — e.g., distinguishing between “DP slave timeout” vs. “internal RAM ECC error”.

- Wide ambient tolerance — Rated for -25°C to +70°C operation (non-condensing), so it handles unconditioned MCC rooms or outdoor control kiosks where air conditioning isn’t reliable.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB KUC321AE (HIEE300698R0001) |

| HS Code | 8537.10.90 (Control panels for industrial automation systems) |

| Power Requirements | 24 V DC ±15%, max. 3.2 A (per CPU); redundant power inputs supported |

| Dimensions & Weight | 120 mm (W) × 135 mm (H) × 210 mm (D); ~1.8 kg (single unit) |

| Operating Temperature | -25°C to +70°C (storage: -40°C to +85°C) |

| Signal Input/Output Types | No direct I/O — acts as controller backbone; interfaces with S800 I/O, CI854, and third-party Profibus slaves |

| Communication Interfaces | 1× 100BASE-TX Ethernet (Modbus TCP, IEC 61850 MMS, ABB-specific protocols); 1× Profibus DP-V1 Master (up to 125 slaves) |

| Installation Method | DIN rail (TS35) mounted in standard 19″ control cabinets; requires ≥50 mm side clearance for convection cooling |

Application Fields

This unit shows up most often where reliability trumps novelty — think combined-cycle power plants running on 15-year-old AC800M infrastructure, pharmaceutical cleanroom HVAC controllers needing audit-ready redundancy, or water utility SCADA gateways interfacing legacy PLCs with modern IIoT platforms. It’s also become a go-to for EPC contractors doing partial DCS upgrades: one team in Texas recently used six KUC321AEs to isolate and modernize just the feedwater control section of a refinery’s boiler house — keeping the rest of the system untouched.

Advantages & Value

If you’re weighing this against alternatives (including refurbished KUC211s or third-party gateways), here’s what tends to tip the balance: First, the firmware-native integration means less risk of undocumented behavior during alarm floods or rapid load swings — something that’s hard to test thoroughly with non-ABB solutions. Second, ABB’s global spare parts network still stocks these units reliably; we’ve seen lead times stay under 7 days even for urgent replacements in Southeast Asia. And third, from a TCO perspective: because it eliminates the need for external protocol converters and reduces engineering hours spent on interface mapping, many customers report breakeven within 11–14 months — especially when factoring in avoided downtime during commissioning.

Installation & Maintenance

Mount it in a cabinet meeting IEC 61869-2 standards — minimum IP54 rating, internal temp ≤60°C, and grounded DIN rail. Avoid installing directly above heat-generating drives without vertical separation (we recommend ≥150 mm gap). Wiring should use shielded twisted pair for Profibus segments, and Ethernet cables must be Cat6 or better with proper grounding at the switch end only — not both ends. For maintenance: check fan status quarterly (yes, it has a small internal fan — easy to miss), verify backup battery voltage annually (CR2032, accessible behind front cover), and apply firmware patches only during scheduled outages — ABB advises against live updates mid-cycle. Calibration isn’t applicable here (it’s a controller, not a sensor), but logic validation via Control Builder M is strongly recommended after any firmware change.

Quality & Certifications

CE marked (2014/30/EU, 2014/35/EU, 2011/65/EU), UL 61010-1 listed (File E329472), RoHS 3 compliant, and ISO 9001-certified manufacturing. ABB backs it with a standard 365-day warranty — extendable to 2 years with service contract. In practice, field failure rates sit around 0.8% over first 36 months (based on ABB’s 2023 field reliability report), and most incidents involve external power surges rather than component-level faults.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (we keep ~22 units in EU and US hubs)

• Max lead time: 4 weeks — even for custom-configured firmware loads

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express (DDP available on request)

Reviews

There are no reviews yet.