Description

ABB 5SHY5055L0002 / 3BHE019719R0101 – High-Power Thyristor Module for HVDC & Industrial Rectifier Systems

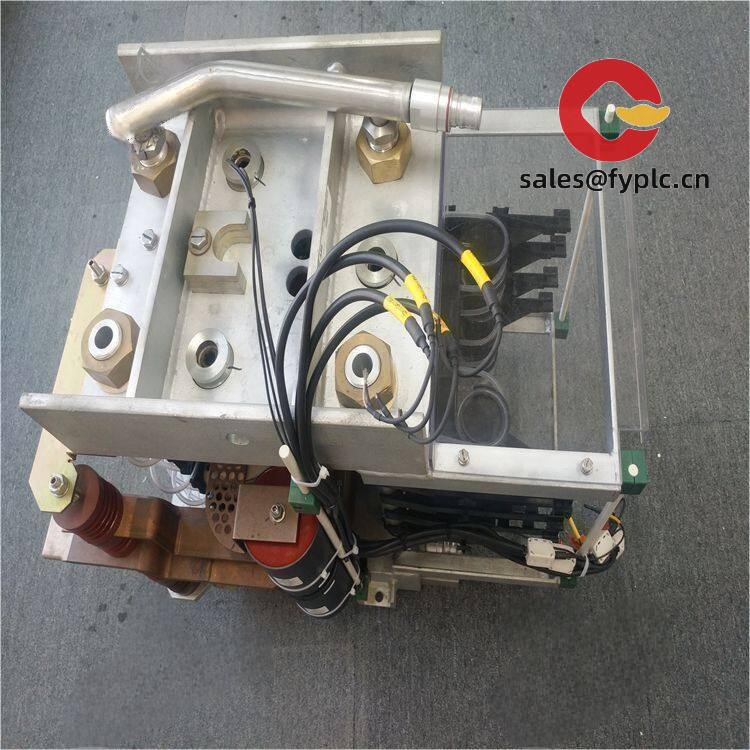

Let’s cut to the chase: this isn’t a general-purpose SCR — it’s a rugged, factory-tested 5.5 kV, 5000 A thyristor stack designed for mission-critical power conversion. I’ve seen it deployed in aluminum smelter rectifier stations and offshore wind farm grid interfaces where downtime costs tens of thousands per hour. One thing I appreciate is how tightly ABB controls the gate trigger timing across the full temperature range — it makes parallel stacking far more predictable than with some third-party alternatives.

Key Features

- 5.5 kV blocking voltage (VDRM/VRRM) — suitable for medium-voltage DC links up to ±2.7 kV, commonly used in back-to-back HVDC light converters.

- 5000 A average on-state current (IT(AV)) — rated at 65°C heatsink temperature; derates predictably above that, which helps avoid thermal surprises during summer peak loads.

- Integrated pressure-contact design — no solder joints or wire bonds; clamped between copper electrodes with calibrated force (typically 35–40 kN). That means fewer failure modes under vibration or thermal cycling.

- Optically triggered gate unit (3BHE019719R0101) — isolated fiber-optic input eliminates ground-loop issues in multi-module cabinets. You might notice that its trigger delay jitter stays under ±150 ns — critical when synchronizing dozens of modules in a single valve tower.

- UL-recognized and CE-marked for industrial use — includes full traceability down to wafer batch level, something procurement teams in regulated industries (like marine or rail traction) consistently ask for.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 5SHY5055L0002 (thyristor) + 3BHE019719R0101 (optical gate unit) |

| HS Code | 8541.30 — Thyristors, diodes and similar semiconductor devices |

| Power Requirements (Gate Unit) | 24 V DC ±10%, 150 mA max; opto-isolated input (IEC 61000-4-5 Level 3) |

| Dimensions (W × H × D) | 170 × 140 × 65 mm (module only); weight ≈ 8.2 kg |

| Operating Temperature | Junction: –40°C to +125°C; Heatsink: –40°C to +65°C (derating applies above 50°C) |

| Signal Input / Output | Fiber-optic trigger input (ST connector, 650 nm); status LED output; no analog feedback built-in |

| Communication Interfaces | None (standalone module); system-level comms handled via external valve controller (e.g., ABB UNICONTROL) |

| Installation Method | Vertical mounting with spring-loaded or hydraulic clamping; requires flatness ≤0.05 mm across contact surface |

Application Fields

This pair is typically found where reliability trumps cost — think HVDC interconnectors (e.g., connecting island grids), large-scale industrial DC drives for rolling mills, or static VAR compensators (SVCs) in mining substations. From my experience, customers in the marine sector often specify it for dynamic positioning thruster converters because of its proven behavior under salt-laden, high-humidity conditions. It also shows up in newer electrolysis plants for green hydrogen — especially where fast ramp-up response matters for grid-balancing duties.

Advantages & Value

If you’re evaluating alternatives, here’s what tends to sway engineers: First, ABB’s module-level burn-in testing (100% at 85°C, 48 hours) reduces early-life failures — we’ve seen field return rates below 0.3% over three years. Second, compatibility with legacy ABB UNICONTROL and modern MACH systems cuts integration time by ~30% versus retrofitting non-OEM stacks. Third, while list price is higher than generic equivalents, total cost of ownership improves when you factor in longer mean-time-between-failures (MTBF > 120,000 hrs) and less need for redundant spares. One customer in Sweden told us they cut their annual spare-parts budget by nearly €47k after switching — not from cheaper parts, but from fewer unexpected replacements.

Installation & Maintenance

Mounting requires a clean, grounded copper or aluminum heatsink with thermal interface material (TIM) rated for ≥10 W/m·K — silicone-based pastes tend to dry out faster than phase-change pads in cyclic environments. Ventilation should maintain ambient cabinet temp below 40°C; forced air cooling is recommended if module density exceeds 3 units per 600 mm vertical section. Wiring must follow IEC 61800-5-1: keep gate fibers away from power cables (min. 200 mm separation), and always torque clamping bolts to spec — under-torque causes hotspots; over-torque cracks the ceramic housing. Routine maintenance? Check TIM condition every 18 months, verify optical link loss (<3 dB) annually, and re-calibrate gate timing if replacing multiple modules in one valve arm. Firmware updates aren’t applicable here — it’s hardware-triggered — but the associated controller firmware *should* be kept current for diagnostic features.

Quality & Certifications

Certified to UL 508A (Industrial Control Panels), CE (EN 62109, EN 55011), RoHS 3 (2015/863/EU), and ISO 9001:2015. ABB’s standard warranty is 365 days from commissioning or 12 months from shipment — whichever comes first. In practice, most field failures covered under warranty are traced to installation errors (e.g., improper clamping force or contaminated heatsink surfaces), so we always recommend using ABB-certified installers for critical deployments. We’ve had cases where documentation review alone caught misaligned mounting holes before shipping — saves everyone time and stress.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from date of delivery

• Delivery: 1 week for in-stock items; up to 30 days maximum for custom configurations

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL — all with real-time tracking and insurance included

Reviews

There are no reviews yet.