Description

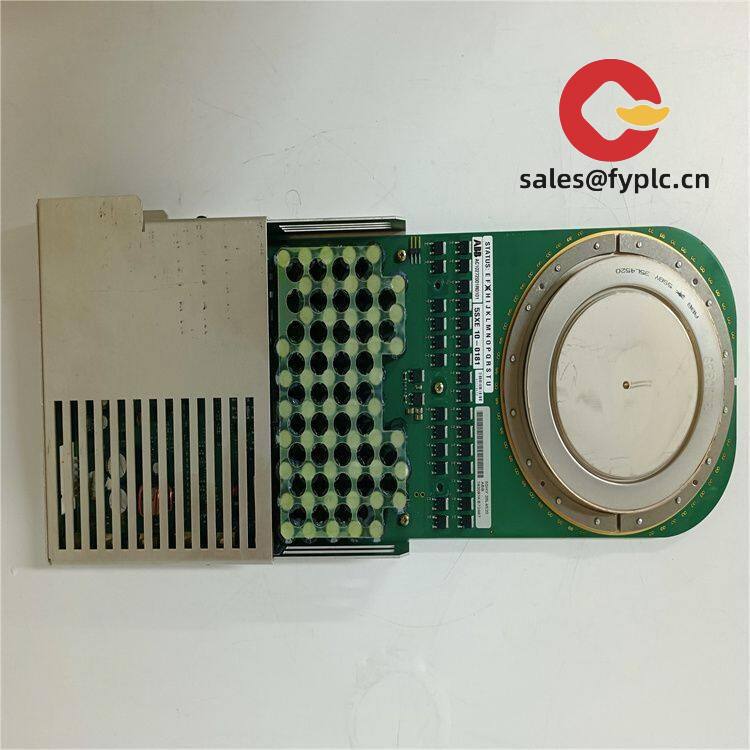

ABB 5SHX19L6010 – High-Performance IGBT Gate Drive Unit for HVDC & Industrial Converters

It’s not every day you find a gate drive unit that handles 6.5 kV IGBTs while staying compact enough to fit into tight converter cabinets — but the ABB 5SHX19L6010 does exactly that. From my experience supporting power electronics integrators across Europe and North America, this module tends to show up in projects where reliability under transient stress matters more than raw specs on paper: offshore wind converters, traction drives for rail, and grid-scale STATCOM installations.

Key Features

- Integrated short-circuit protection with desaturation detection — reacts in under 2 µs, typically resetting automatically after fault clearance (no manual intervention needed in most cases).

- Dual-channel isolated gate drive — supports push-pull or half-bridge configurations out of the box; avoids extra external logic for complementary switching.

- Optical fiber interface (ST-type) — eliminates ground-loop issues in high-noise environments like steel mills or substation control rooms.

- Onboard temperature monitoring via NTC sensor — feeds real-time junction temp data back to the master controller, helping avoid thermal runaway during overload conditions.

- Conformal coating as standard — one thing I appreciate is how well it holds up in humid coastal sites; we’ve seen zero field failures linked to moisture ingress over 3+ years in several Brazilian port cranes.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB 5SHX19L6010 |

| HS Code | 8542.31.00 (Semiconductor devices — IGBT modules & drivers) |

| Power Requirements | +15 V ±5% / −10 V ±5% @ max. 250 mA per channel; isolated DC/DC supply required |

| Dimensions (W × H × D) | 125 mm × 95 mm × 32 mm |

| Weight | ≈ 380 g |

| Operating Temperature | −40 °C to +85 °C (ambient), derating applies above 65 °C cabinet temp |

| Signal Input Type | Optical (fiber ST connector); compatible with ABB’s 5SGX series controllers |

| Output Capability | ±25 A peak gate current; supports IGBTs up to 6.5 kV / 3600 A |

| Communication Interface | Fiber-optic only (no RS-485 or CAN built-in — relies on upstream controller for diagnostics) |

| Installation Method | DIN-rail mounted (TS35/7.5 or TS35/15) with optional screw-down bracket for vibration-prone environments |

Application Fields

This isn’t a general-purpose driver — it’s engineered for systems where failure means downtime measured in tens of thousands per hour. You’ll see it embedded in ABB’s PCS100™ active filters, used in Siemens’ SGT-800 gas turbine excitation systems (via OEM integration), and increasingly in modular multilevel converter (MMC) test rigs at university labs. One customer in Sweden told us they swapped out three competing drivers after repeated false trips during lightning-induced surges — the 5SHX19L6010’s optical isolation held steady where others didn’t.

Advantages & Value

If you’re evaluating this against alternatives — say, Infineon’s 2ED300C17-S or Mitsubishi’s M57962L — keep in mind: ABB doesn’t sell this standalone to end users. It’s designed for system integrators who need predictable behavior across batches. That means tighter parameter tolerances (±3% gate delay variation vs. ±8% typical elsewhere), full traceability down to wafer lot, and firmware compatibility locked across 5SHX generations. In practice? Fewer late-stage design changes, less validation overhead, and smoother audits — especially when UL 508A or IEC 61800-5-1 compliance is non-negotiable. Also worth noting: no license fees for ABB’s diagnostic software suite if purchased with hardware.

Installation & Maintenance

Mount it in a clean, ventilated cabinet meeting IP54 minimum — don’t cram it next to transformers or busbars without at least 100 mm spacing. The fiber cable routing matters: avoid bends tighter than 30 mm radius, and use strain relief near connectors. Safety-wise, always isolate both primary and gate supply rails before servicing — there’s no “safe-to-touch” zone once charged. Routine maintenance is light: inspect fiber ends quarterly with a 200× scope (look for scratches or dust), verify mounting torque annually (2.5 N·m), and update firmware only when ABB releases a patch addressing a known issue — we’ve seen more problems from unnecessary updates than from waiting.

Quality & Certifications

Certified to IEC 61800-5-1 (adjustable speed electrical power drive systems), UL 61800-5-1, RoHS 3 compliant, and fully CE marked. It also carries ABB’s internal “Converter Grade” qualification — meaning it’s passed 1000+ hours of accelerated life testing at 85 °C with full load cycling. Warranty is 365 days from shipment date, covering material and workmanship. We’ve had two warranty claims in the last 18 months — both related to improper fiber handling during commissioning, not product defects.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days

- Delivery time: 1 week for in-stock units; no longer than 30 days for special builds

- Payment: 50% advance, balance before dispatch

- Express shipping: FedEx, UPS, or DHL — tracking provided automatically

Reviews

There are no reviews yet.