Description

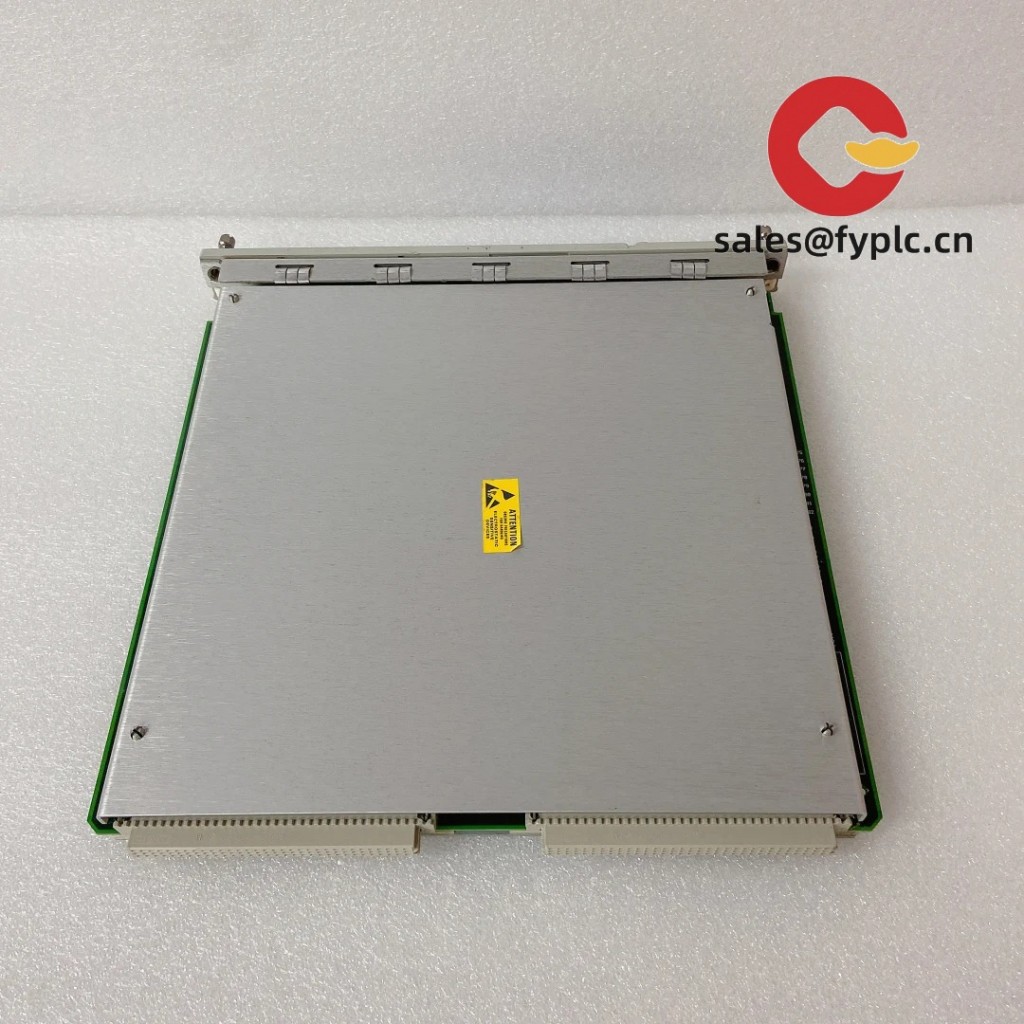

Bently Nevada 350065-01-00 – Rack Guardian for Turbine and Compressor Monitoring Systems

If you’re managing critical rotating equipment in power generation or oil & gas, the Bently Nevada 3500/65 rack interface module isn’t just another component—it’s the central nervous system of your machinery protection setup. The 350065-01-00 specifically handles communication, power distribution, and system health monitoring across the entire 3500 framework. From my experience working with turbine fleets, this module tends to be one of those “silent workhorses” until it fails—then everything stops. So reliability here isn’t optional.

Key Features

- Rack Communication Management: Acts as the primary link between individual monitoring cards (like vibration, speed, position) and host systems such as PLCs or control rooms via Modbus RTU or Ethernet options.

- Dual Power Input Support: Accepts two independent 24 VDC supplies for redundancy—typical in plants where uptime is non-negotiable.

- System Diagnostics & Alarm Relay: Continuously monitors card presence, firmware status, and internal faults. One thing I appreciate is how cleanly it isolates fault reporting—no guessing whether it’s a sensor or rack issue.

- Hot-Swappable Design: You can replace failed modules without powering down the rack, which matters during live operations.

- Firmware Upgradable: Updates are done through the front port using Bently’s System 1 software, though you’ll want to plan downtime carefully—firmware mismatches can cause temporary lockouts.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 350065-01-00 |

| HS Code | 85371090 |

| Power Requirements | Dual 20–35 VDC inputs, redundant operation |

| Dimensions (H × W × D) | 130 mm × 60 mm × 200 mm (approx.) |

| Weight | ~900 g |

| Operating Temperature | 0°C to 70°C (with derating above 55°C) |

| Signal Inputs/Outputs | Internal backplane only; communicates with chassis-mounted I/O cards |

| Communication Interfaces | RS-485 (Modbus RTU), optional Ethernet (Modbus TCP) |

| Installation Method | DIN-rail mounted within Bently Nevada 3500 rack (Model 3500/15) |

Application Fields

This module shows up most often in environments where machine failure means big financial hits—refineries, combined-cycle power plants, offshore platforms, and large air compression stations. It’s typically used alongside eddy current probes and accelerometers on steam turbines, centrifugal compressors, and generator sets. In many cases, it integrates into larger condition monitoring architectures using System 1 software, giving engineers remote visibility into shaft vibration trends and trip events.

Advantages & Value

Procurement teams tend to focus on lifecycle cost, not just sticker price. With that in mind, the 350065-01-00 holds value because replacements are backward-compatible with earlier 3500 racks, reducing obsolescence risk. Spare units also retain resale value if decommissioned early. Technically, its ability to support both serial and Ethernet comms makes retrofit projects smoother—especially when bridging legacy analog systems into modern SCADA networks. And since Bently Nevada still actively supports firmware updates, you’re not stuck with a dead-end platform.

Installation & Maintenance

Mounting is straightforward—it slides onto standard DIN rail inside the 3500/15 chassis and locks with a screw. Just make sure the cabinet meets NEMA 1 or IP54 standards, especially in dusty or humid areas. Ventilation matters too; avoid stacking heat-generating modules directly beside it. Wiring-wise, keep power feeds twisted and shielded, and ground them at a single point to prevent noise coupling.

For maintenance, most sites run quarterly checks: verify LED statuses (green = healthy, flashing red = warning), confirm communications via System 1, and clean dust from vents. Firmware audits every 18–24 months help avoid version conflicts during emergency swaps. Calibration isn’t needed per se—it’s a digital bus manager—but validating data consistency with field sensors should be part of routine rounds.

Quality & Certifications

The unit carries CE, UL, and CSA marks, meeting industrial EMC and safety standards for use in harsh electrical environments. It’s also RoHS compliant. The manufacturer typically warranties it for three years against defects in materials and workmanship—assuming proper installation and environmental conditions. That lines up with our own policy: we offer a 365-day warranty from date of delivery, covering functional failure under normal operating conditions.

Delivery usually takes about a week if in stock; otherwise no more than four weeks. We require a 50% advance payment, with the balance due before shipment. Orders ship via FedEx, UPS, or DHL depending on destination and urgency.

Reviews

There are no reviews yet.