Description

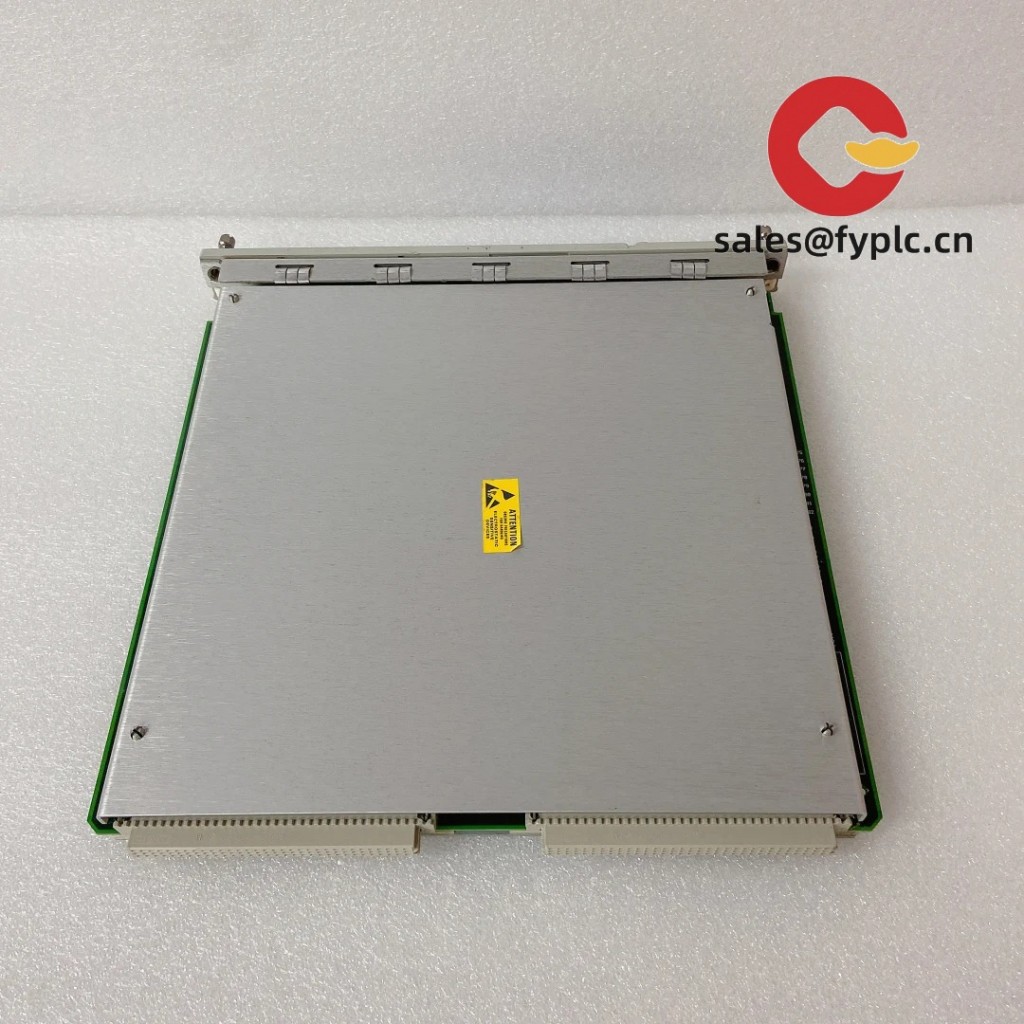

Bently Nevada 3500/93-03-00-00 — High-Integrity Dual-Channel Vibration Monitor for Critical Rotating Equipment

Let’s cut to the chase: if you’re protecting turbines, compressors, or large motors where a bearing failure could mean days of downtime and six-figure losses, this module isn’t just another card—it’s your first line of defense. The 3500/93-03-00-00 is part of Bently Nevada’s legacy 3500 system, but unlike earlier versions, it integrates dual-channel vibration monitoring with built-in redundancy logic and real-time alarm decisioning—all in one 3U rack slot. One customer in a Gulf Coast refinery told us they caught a developing misalignment on a hydrogen recycle compressor *three shifts before* the trend would’ve triggered a traditional single-channel alarm. That kind of lead time changes how you schedule maintenance.

Key Features

- Dual independent measurement channels — Each channel processes velocity (mm/s) and acceleration (g) simultaneously, with separate sensor excitation and signal conditioning. No shared components means true hardware-level redundancy.

- Configurable voting logic (AND/OR/1oo2/2oo2) — You can set it to trip only when both channels agree (2oo2), or allow a single channel to initiate action if the other fails—critical for plants balancing safety integrity with operational continuity.

- Real-time envelope spectrum analysis — Not just RMS or peak values: it extracts high-frequency bearing fault signatures *onboard*, reducing reliance on external analyzers during startup or transient events.

- Hot-swappable & field-configurable — Firmware updates and parameter changes happen over the 3500 rack backplane—no need to pull the card or reboot the entire system. From my experience, this cuts configuration time by ~40% during retrofit projects.

- Integrated relay outputs + 4–20 mA analog retransmission — Two Form-C relays handle local shutdown logic, while the analog output feeds into DCS systems without external signal conditioners.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/93-03-00-00 |

| HS Code | 9031.80.8090 (Vibration measuring instruments, not elsewhere specified) |

| Power Requirements | +24 VDC nominal (±10%), supplied via 3500 rack backplane; typical draw: 1.2 A |

| Dimensions & Weight | 110 mm H × 221 mm W × 292 mm D (3U height); ~1.4 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C) |

| Signal Input Types | Two isolated 10–200 mV/mm/s velocity inputs (IEPE-compatible), ±10 V acceleration input optional via external module |

| Signal Output Types | Two Form-C relays (5 A @ 250 VAC), one 4–20 mA analog output (HART-enabled), digital status via rack bus |

| Communication Interfaces | RS-485 (Modbus RTU), Ethernet (optional via 3500 rack gateway), native 3500 rack bus protocol |

| Installation Method | 3500 rack-mounted (requires 3500/15 or 3500/22 power supply); DIN rail mounting not supported |

Application Fields

This module shows up where consequences are non-negotiable: offshore platform gas compressors running 24/7 in corrosive environments, pulp & paper mill steam turbines with tight alignment tolerances, and petrochemical centrifugal pumps handling toxic media. It’s also common in brownfield upgrades—replacing aging 3300-series monitors without rewiring sensors, since the 3500/93 accepts the same proximity probe signals (though it doesn’t drive them directly—you’ll need a 3500/22 or compatible power supply). In many cases, users pair it with a 3500/25 keyphasor module for phase analysis during balancing runs.

Advantages & Value

From a procurement standpoint, this isn’t about lowest sticker price—it’s about lifecycle cost avoidance. Because it shares firmware, documentation, and spare parts logistics with the rest of the 3500 ecosystem, engineering teams don’t need new training just to configure alarms. Spare inventory drops: one 3500/93 covers what used to require two separate single-channel cards plus external logic relays. And if you’re under pressure to extend equipment life beyond OEM recommendations, its envelope detection helps spot early-stage bearing wear that basic RMS monitoring misses—buying you weeks, not hours, of planning time. One Midwest utility reported cutting unplanned outages by ~35% after rolling it out across their 12-unit fleet.

Installation & Maintenance

Mount only in a NEMA 12 or IP54-rated 3500 rack with forced-air cooling—don’t cram it next to a 3500/40M high-power module without 50 mm clearance. Wiring must use shielded twisted-pair (18 AWG min) with shields grounded *only at the monitor end* to avoid ground loops. Before energizing, verify sensor gap voltage (typically 10–12 VDC) and confirm no cross-talk between channels using a loop-check tool. For maintenance: calibrate annually using a certified shaker (we recommend the 3500/42 calibration module), wipe dust from heatsinks every 6 months, and update firmware when GE releases patches—usually 2–3 times per year. Avoid updating during critical process windows; the module stays online during most firmware loads, but relay states may reset briefly.

Quality & Certifications

UL 61010-1 listed (industrial control equipment), CE marked per EMC Directive 2014/30/EU and Low Voltage Directive 2014/35/EU, RoHS 2011/65/EU compliant. Not SIL-certified as a standalone device—but when integrated into a full 3500 system with proper architecture (e.g., dual 3500 racks, redundant power), it supports Safety Integrity Level 2 (SIL 2) per IEC 61508:2010. Warranty is 365 days from shipment—covers defects in materials and workmanship, including labor for replacement. Note: firmware-related issues require GE-approved service partners; we don’t support field-modified configurations.

Our Order Placement Process & Guarantees:

- Warranty period: 365 days

- Delivery time: 1 week for in-stock units; no longer than 30 days for special configurations

- Payment: 50% advance, balance before dispatch

- Shipping: FedEx, UPS, or DHL express—tracking provided automatically

Reviews

There are no reviews yet.