Description

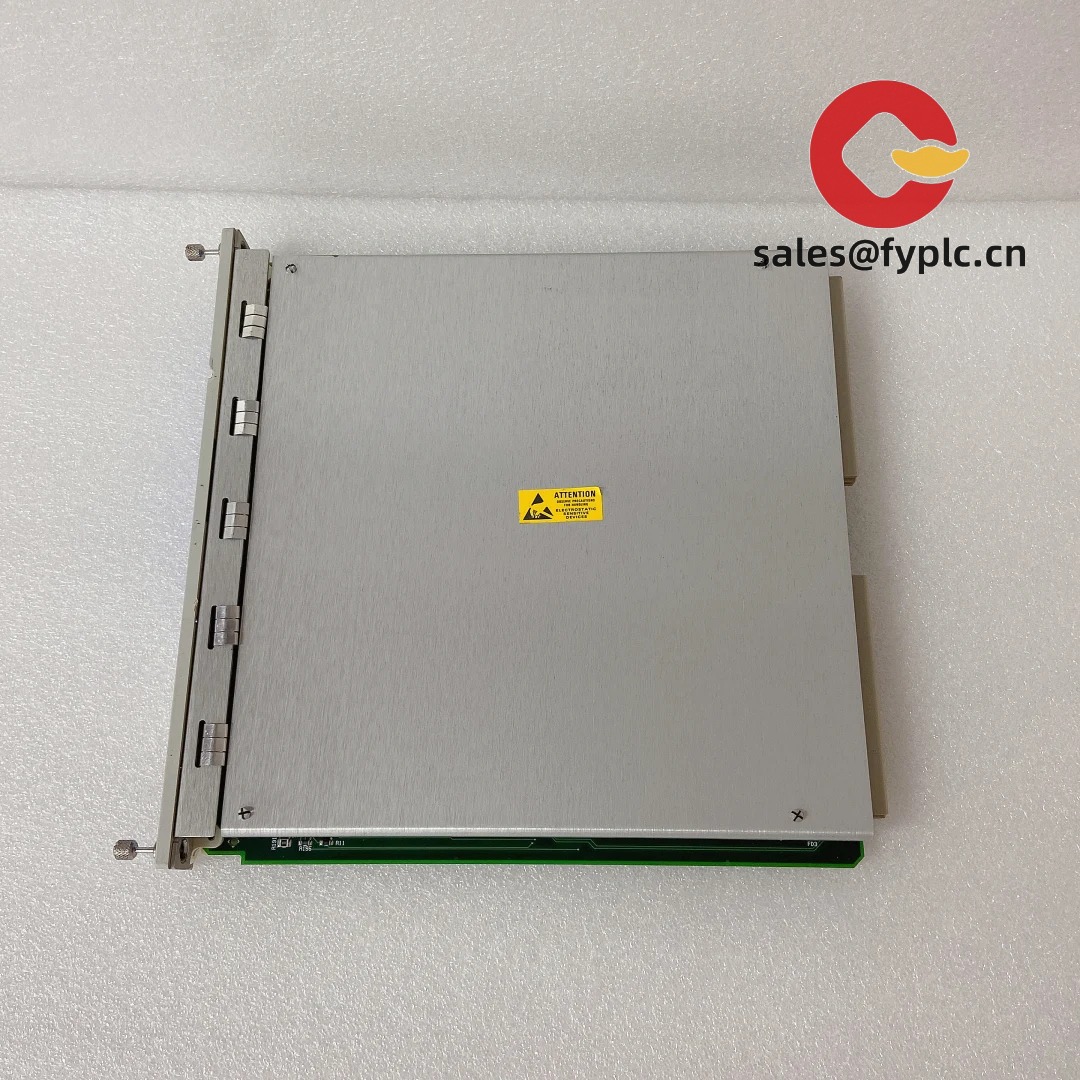

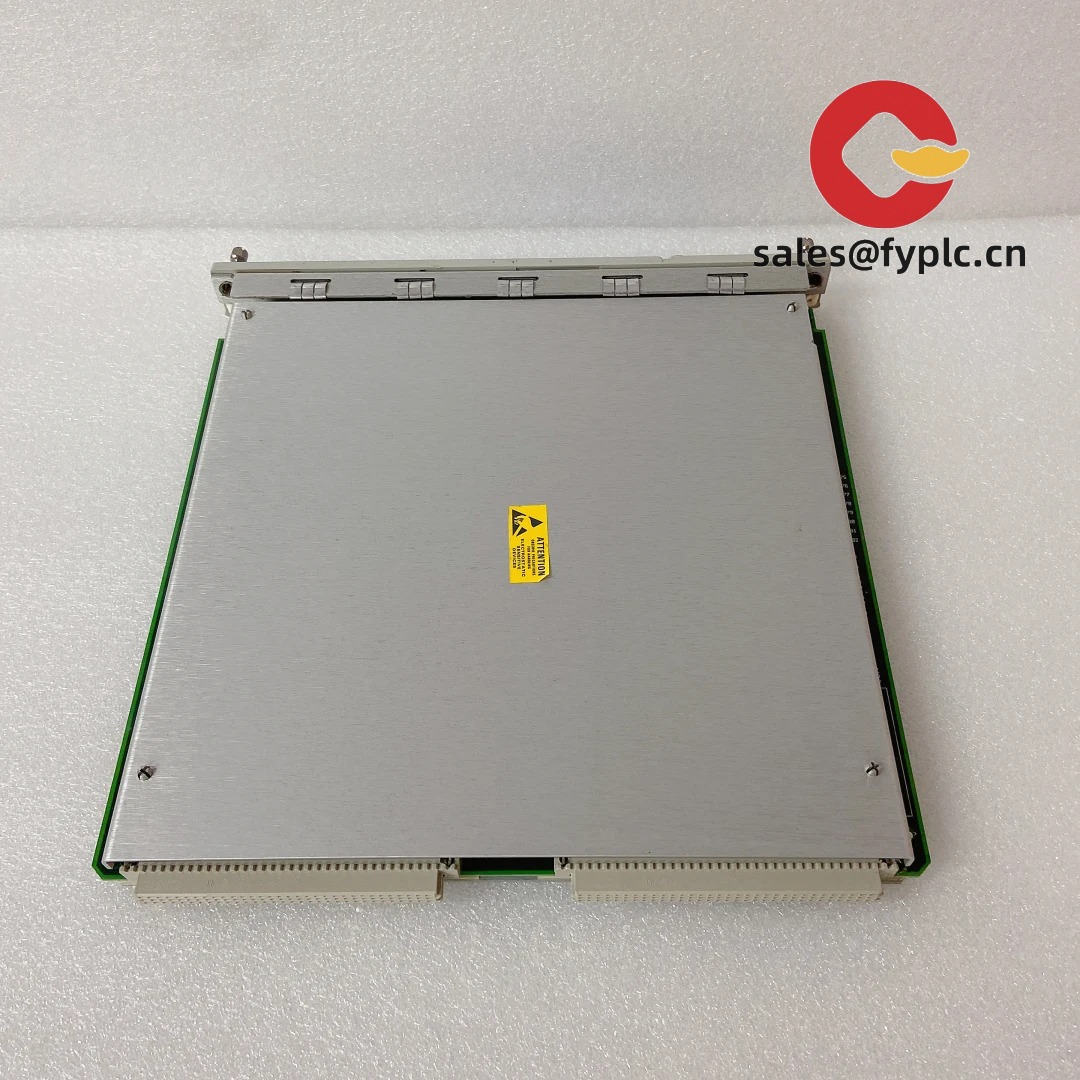

Bently Nevada 3500/92-04-01-00 — Dual-Channel Proximitor Monitor for Radial Vibration & Position Monitoring

One thing I appreciate is how consistently this module shows up in retrofit projects across oil & gas turbocompressors and power plant steam turbines — not because it’s flashy, but because it just works, year after year. From my experience, most users reach for the 3500/92 when they need a drop-in replacement that maintains legacy 3500 rack compatibility while delivering stable, low-noise DC output for proximity probes (like the 3300 series). It’s not the newest monitor on the shelf, but in many cases, it’s the most trusted.

Key Features

- Dual independent channels — Each monitors one proximity probe (e.g., radial vibration + axial position), with separate alarm and OK relays. You might notice that channel isolation helps avoid cross-talk during startup transients.

- DC output scaling (–2 to –18 VDC) — Matches standard proximitor input ranges for PLCs and DCS systems. Typically used with 5 mm or 8 mm probes; calibration is straightforward via front-panel potentiometers (no software required).

- Configurable alarm logic — High/High, High, and OK relays per channel — wired for fail-safe operation. In practice, customers often wire the “OK” relay to inhibit start-up until probe bias and gap are verified.

- Rack-mounted, hot-swappable — Fits into any Bently Nevada 3500 rack (e.g., 3500/15, 3500/22). No firmware update needed — it powers up ready to go, even after years in storage.

- Integrated bias supply (–24 VDC) — Powers two proximity probes directly. Saves panel space vs. external bias modules — especially helpful in crowded retrofit cabinets.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/92-04-01-00 |

| HS Code | 8531.80.90 (Monitoring instruments for industrial process control) |

| Power Requirements | 24 VDC ±10%, 120 mA typical (rack-supplied) |

| Dimensions & Weight | 172 × 42 × 235 mm (W×H×D); ~0.9 kg |

| Operating Temperature | 0 °C to +60 °C (derates above 50 °C) |

| Signal Input | Two independent proximity probe inputs (–2 to –18 VDC, 4–20 mA optional with external shunt) |

| Signal Output | Two isolated 4–20 mA outputs (configurable range), plus three Form-C relays per channel |

| Communication Interface | None (local configuration only; status visible via LED indicators) |

| Installation Method | 3500 rack-mount (hot-swappable); requires compatible 3500/15 or 3500/22 power supply |

Application Fields

This monitor is routinely deployed where mechanical integrity monitoring is non-negotiable: centrifugal compressor trains in LNG facilities, hydroelectric generator sets, air separation units, and refinery FCC blowers. A recent customer in Texas told us they’ve run six of these in parallel on a 20-year-old 3500 rack — no failures, no drift, and zero recalibration over 14 years. It’s also common in OEM skids where simplicity trumps connectivity: if your control system reads 4–20 mA and needs hardwired alarms, the 3500/92 fits without requiring Ethernet switches, OPC servers, or cybersecurity reviews.

Advantages & Value

Procurement teams typically prioritize three things with this unit: interchangeability, supply chain resilience, and low TCO. Since it’s a mature part (no EOL notices as of Q2 2024), lead times stay predictable — and unlike newer Ethernet-based monitors, you won’t face firmware version lock-in or mandatory gateway upgrades. It integrates cleanly with existing 3500 infrastructure, so engineering time stays low. And because it draws minimal power and has no fans or moving parts, cabinet cooling requirements stay simple — which matters when you’re squeezing gear into an aging MCC room.

Installation & Maintenance

Mount only in a grounded, NEMA 12-rated 3500 rack with ≥100 mm clearance above/below for convection cooling. Avoid mounting near high-EMI sources like VFDs or contactors — we’ve seen minor noise pickup on unshielded probe cables in those setups. Wiring must use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields grounded at the monitor end only. For maintenance: visually inspect LEDs quarterly; clean dust from vents annually with compressed air (never solvents); verify calibration every 24 months using a calibrated test set — though many users extend this to 36 months with stable historical trend data. Firmware updates aren’t applicable — there’s no embedded processor to update.

Quality & Certifications

CE marked (2014/30/EU, 2014/35/EU), UL 61010-1 certified (E456277), RoHS 2011/65/EU compliant. Backed by a full 365-day warranty — covering parts and labor, with no exclusions for field-installation errors. If you need documentation, the original manual (3500/92 Manual 022-000-000) is still available digitally from Baker Hughes’ support portal.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week for in-stock units (we hold active inventory on this model)

• Max lead time: 4 weeks — rare, but possible if factory allocation shifts

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express — fully insured, with real-time tracking

Reviews

There are no reviews yet.