Description

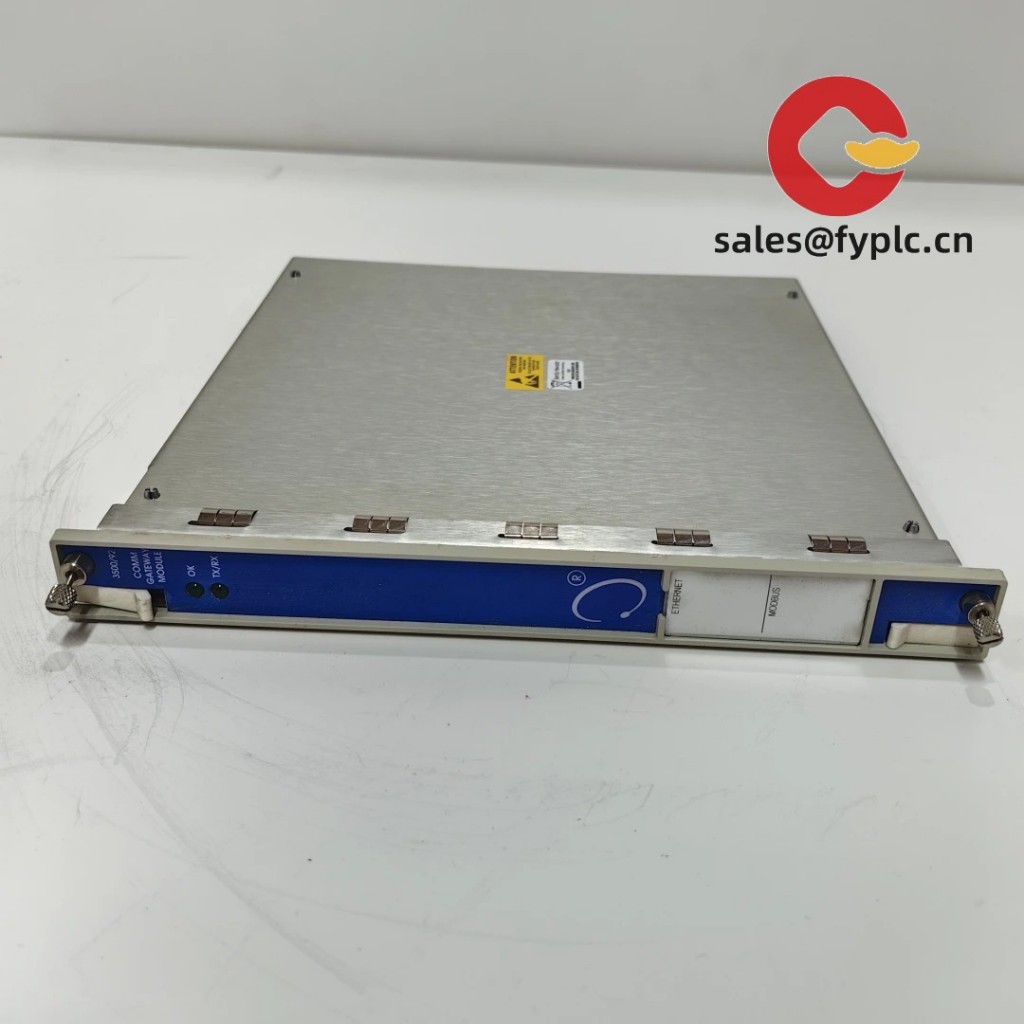

Bently Nevada 3500/92 Proximitor Monitor (Model 136188-01) — High-Integrity Vibration Monitoring for Rotating Machinery

Let’s cut to the point: if you’re protecting critical turbines, compressors, or large motors—and you’ve ever lost production due to undetected shaft displacement or probe drift—you’ll recognize why this module still shows up in brownfield retrofits and new OEM panels alike. The 3500/92 isn’t flashy, but it’s one of those rare industrial components that quietly earns trust over 15+ years in the field.

Key Features

- Dual-channel monitoring with independent calibration — Each channel handles its own proximity probe (e.g., 3300 series), letting you monitor radial vibration + axial position simultaneously—no shared gain drift or crosstalk.

- True RMS and peak detection built-in — Not just peak-to-peak averaging; it calculates true RMS for vibration severity assessment, which matters when diagnosing bearing faults or resonance conditions.

- Configurable alarm logic with time-delayed latching — You can set independent high/low alarms per channel, plus delay timers (0–10 sec) to avoid nuisance trips during startup transients.

- Redundant power input (24 VDC ±10%) — Accepts dual isolated supplies—useful in safety-critical loops where a single power failure shouldn’t blind your protection system.

- Front-panel LED status & local test button — No software needed for basic verification: press the test button and watch LEDs confirm channel activity, alarm states, and OK status—all while live.

Technical Specifications

| Parameter | Specification |

|---|---|

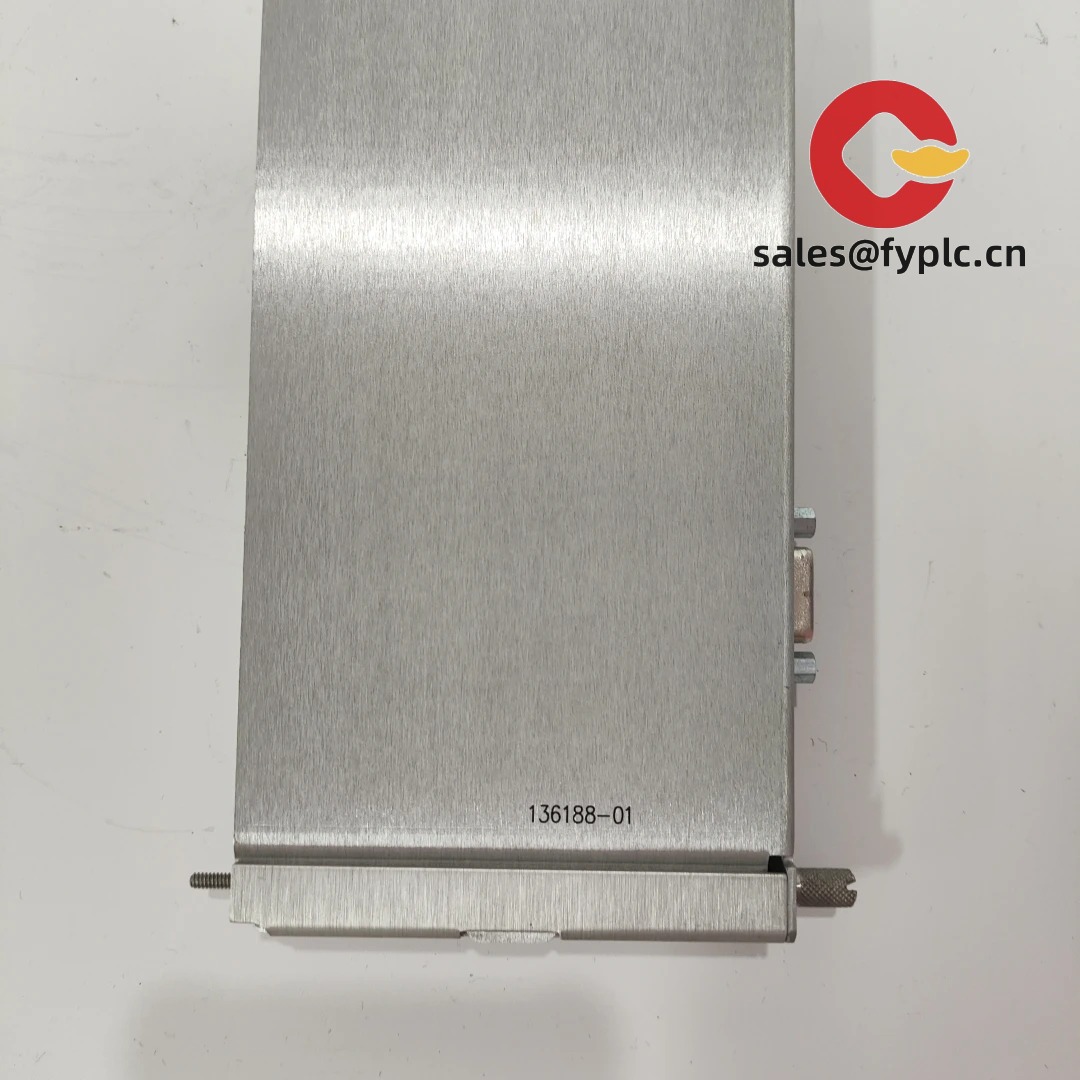

| Brand / Model | Bently Nevada 3500/92 (136188-01) |

| HS Code | 8531.80.90 (Monitoring instruments for industrial process control) |

| Power Requirements | 24 VDC ±10%, 120 mA typical (dual-input capable) |

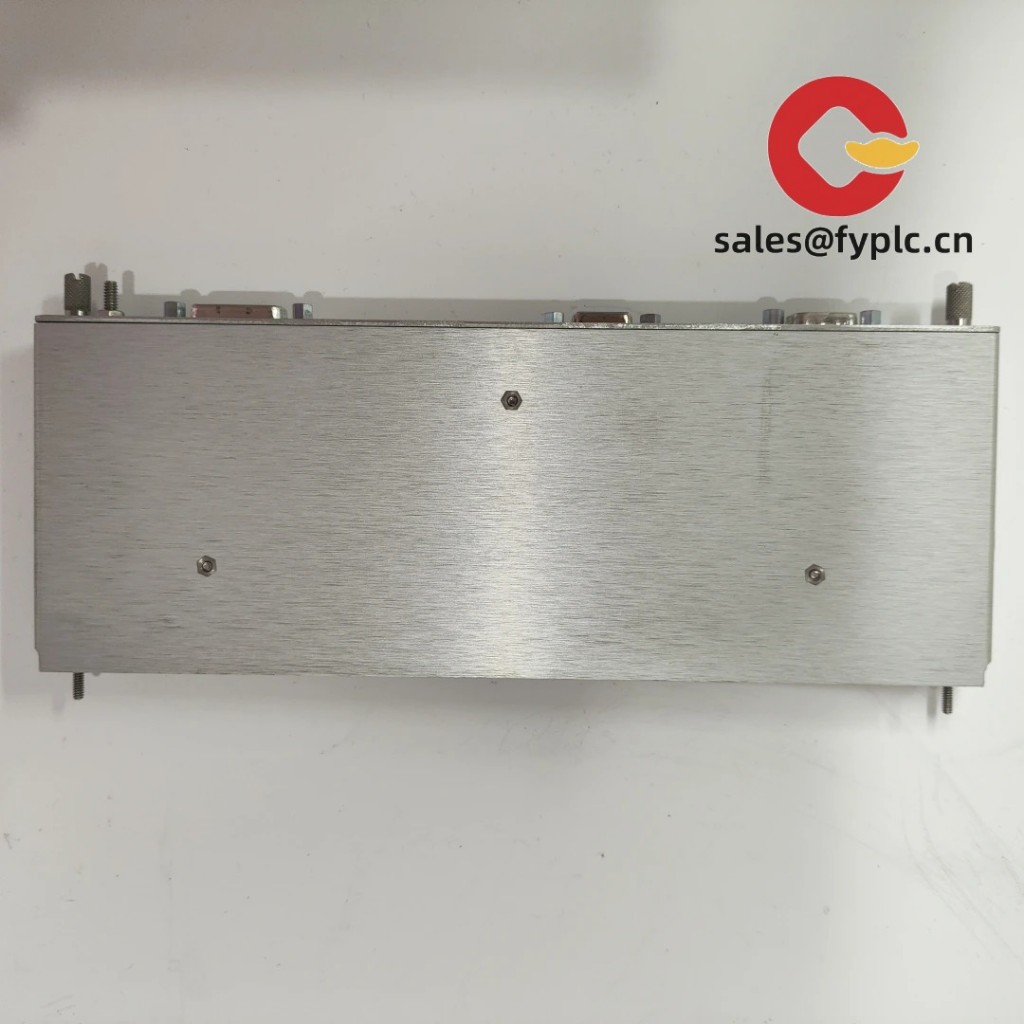

| Dimensions & Weight | 173 mm H × 42 mm W × 270 mm D; ~0.95 kg |

| Operating Temperature | −30 °C to +65 °C (derated above 55 °C) |

| Signal Input Type | Two 3300-series proximity probe inputs (−24 VDC bias, 4–20 mA compatible with some configurations) |

| Signal Output Types | 4–20 mA analog outputs (per channel), relay outputs (2 form-C, 5 A @ 250 VAC) |

| Communication Interface | RS-232 (front-panel port for configuration via 3500 Rack Configuration Software) |

| Installation Method | DIN-rail mounted inside Bently Nevada 3500 rack (requires 3500/15 or 3500/22 power supply) |

Application Fields

This module is routinely found where uptime meets consequence: offshore gas compression trains (e.g., GE PCL or Solar Titan units), refinery air blower systems, hydroelectric generator sets, and pulp & paper mill dryers. One customer in Alberta told us they kept a 3500/92 online for 17 years on a 20 MW steam turbine—only replacing it after a cabinet redesign. It’s not “legacy” in the obsolete sense; it’s legacy in the “still doing the job no one wants to risk changing” sense.

Advantages & Value

From a procurement standpoint, the 3500/92 delivers predictability—not novelty. Spare parts are still stocked globally, firmware updates are infrequent but well-documented, and integration into existing 3500 racks takes minutes. You won’t save money by switching to a newer platform unless you’re also upgrading the entire rack—and even then, backward compatibility is often limited. In many cases, keeping the 3500/92 avoids revalidation costs for API 670-compliant machinery protection systems. And yes—it’s more expensive upfront than generic PLC-based alternatives, but downtime from misdiagnosed shaft orbit events tends to cost 10× more per incident.

Installation & Maintenance

Mount only in a NEMA 12 or IP54-rated cabinet with forced ventilation—this unit doesn’t run hot, but ambient temperature stability matters for long-term probe offset drift. Keep wiring separated: shielded twisted-pair for probe inputs (grounded at monitor end only), and avoid routing near VFD output cables. Calibration should be verified annually using a known-good calibrator (e.g., Bently’s 1900-01); cleaning is minimal—just compressed air every 6 months if installed in dusty environments. Firmware updates are rare (last stable release was v4.12 in 2021), but always back up configuration before applying.

Quality & Certifications

CE marked (2014/30/EU, 2014/35/EU), UL 61010-1 listed (File E137227), RoHS 3 compliant, and designed to meet API RP 670 (4th ed.) requirements for machinery protection. Backed by a full 365-day warranty—no pro-rata clauses, no “parts-only” exclusions. If it fails under normal operating conditions, we replace the module outright.

Our Order Placement Process & Guarantees:

- Warranty: 365 days, full replacement

- Delivery: 1 week for in-stock units; ≤30 days maximum for special requests

- Payment: 50% advance, balance before shipment

- Shipping: FedEx, UPS, or DHL—fully tracked, insured, and documented

Reviews

There are no reviews yet.