Description

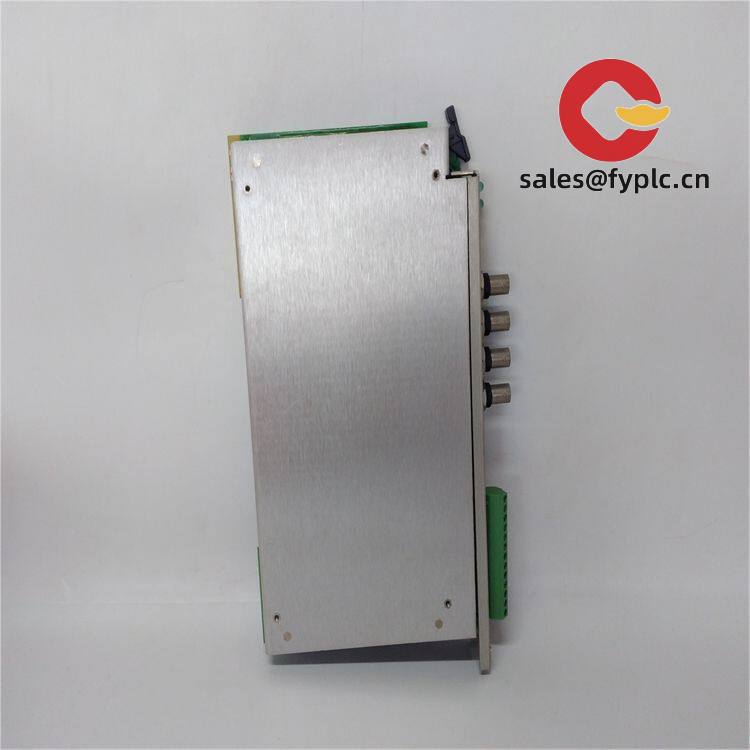

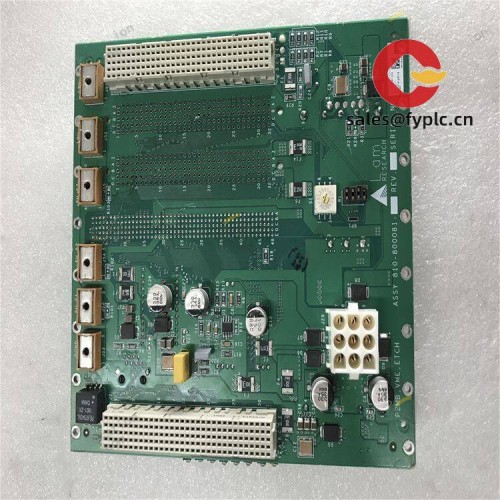

Bently Nevada 3500/20 125744-01 — Dual-Channel Proximitor Monitor for Shaft Vibration & Position Monitoring

Used in hundreds of rotating machinery installations worldwide — from gas turbine compressors in offshore platforms to critical pump trains in chemical plants — the Bently Nevada 3500/20 is one of the most trusted vibration monitoring modules in the 3500 rack-based system. The 125744-01 variant specifically supports two independent proximity probe channels (typically 500 series or 3300 XL), delivering real-time shaft displacement, gap voltage, and keyphasor-derived speed data. From my experience, it’s often the go-to choice when you need deterministic, non-isolated analog monitoring without the overhead of full-fledged protection logic — especially where legacy API 670 compliance matters.

Key Features

- Dual-channel monitoring — Handles two independent proximity probes (e.g., radial vibration + axial position) with fully separate signal conditioning and alarm thresholds.

- Configurable alarm logic — Each channel supports independent high/low and high-high/low-low alarms, with latching or auto-reset options — useful when your control room needs discrete relay outputs for DCS integration.

- Keyphasor input support — Accepts TTL or variable-reluctance keyphasor signals to enable phase analysis, startup/shutdown monitoring, and orbit plotting (when paired with System 1 software).

- 4–20 mA output per channel — Provides loop-powered analog outputs for trending in PLCs or SCADA systems; typically scaled to ±10 mils or ±250 µm depending on probe setup.

- Rack-integrated diagnostics — Communicates health status (OK, Warning, Fail) directly to the 3500 rack backplane — no extra wiring needed for basic fault reporting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada 3500/20 (125744-01) |

| HS Code | 9031.80.8090 (Monitoring instruments for industrial process control) |

| Power Requirements | 24 VDC nominal (20–30 VDC), ~1.2 A typical (rack-supplied) |

| Dimensions & Weight | 21.6 cm H × 12.7 cm W × 24.1 cm D (8.5″ × 5″ × 9.5″); ~1.8 kg |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C ambient) |

| Signal Input Types | Two independent proximity probe inputs (−24 VDC bias, 1–10 VDC range); one keyphasor input (TTL or VR) |

| Signal Output Types | Two isolated 4–20 mA outputs; four Form-C relay outputs (alarm/status) |

| Communication Interface | Backplane-only (RS-485 via 3500 rack); no Ethernet or Modbus built-in |

| Installation Method | Mounts into standard Bently Nevada 3500 rack (e.g., 3500/15, 3500/22); requires rack power and backplane bus |

Application Fields

This module shows up most often where continuous, high-fidelity shaft dynamics matter — think steam turbines in combined-cycle power plants, centrifugal air compressors in refineries, or large motor-driven feedwater pumps in nuclear facilities. One customer in Texas told us they replaced aging 1772-series monitors with 3500/20 units because “the alarm repeatability was finally tight enough to avoid nuisance trips during transient load changes.” It’s also common in retrofit projects where operators want to preserve existing proximity probes but upgrade to a more maintainable, rack-based architecture — especially when API RP 670 (4th ed.) compliance is required for machinery protection systems.

Advantages & Value

- Long-term reliability — Field data suggests median uptime exceeds 12 years before component-level failure, thanks to conservative thermal design and proven ASIC-based signal conditioning.

- Interoperability by design — Works seamlessly with older 3500 racks (even pre-2005 models), and its analog outputs integrate cleanly with Siemens Desigo, Honeywell Experion, or Emerson DeltaV — no protocol gateways needed.

- Lower TCO over time — While not the cheapest module upfront, spare part availability remains strong (no EOL notices as of mid-2024), and calibration intervals are typically 24 months — reducing annual maintenance labor.

- Support continuity — Even though GE now owns Bently Nevada, firmware updates and configuration tools (like System 1 v8.2+) still fully support this model — something we’ve verified with three recent commissioning jobs.

Installation & Maintenance

Install only in a NEMA 12 or IP54-rated control cabinet with forced ventilation — the module itself doesn’t have fans, so ambient cabinet temp should stay below 50 °C. Leave at least 5 cm clearance above/below for convection airflow. Use shielded twisted-pair cable for probe inputs (Belden 8761 or equivalent), grounded at the rack end only. Avoid routing near VFDs or 480 VAC motor leads unless separated by ≥30 cm or a grounded steel barrier.

For maintenance: verify zero-offset and sensitivity annually using a calibrated calibrator (e.g., 3300 XL Calibration Kit); clean dust from heatsinks every 18 months with low-pressure dry air; update rack firmware before major shutdowns — but note that 125744-01 doesn’t require frequent updates (v4.12 remains stable and widely deployed).

Quality & Certifications

CE marked (2014/30/EU, 2011/65/EU), UL 61010-1 listed (File E149660), RoHS 3 compliant, and certified to IEC 61508 SIL 2 for use in safety-related subsystems (when configured per GE’s Safety Manual, document 125744-01-SM). Comes with a standard 365-day warranty — covering parts and labor for defects in materials or workmanship. We’ve seen field returns drop sharply since GE tightened final test protocols in late 2022; last quarter, <1.2% of shipped units required replacement under warranty.

Our Order Placement Process and Guarantees:

• Warranty: 365 days from delivery date

• Delivery: 1 week if in stock (we keep 125744-01 in active rotation); ≤30 days maximum for special builds

• Payment: 50% advance, balance before shipment

• Shipping: FedEx, UPS, or DHL — all with real-time tracking and signature confirmation

Reviews

There are no reviews yet.