Description

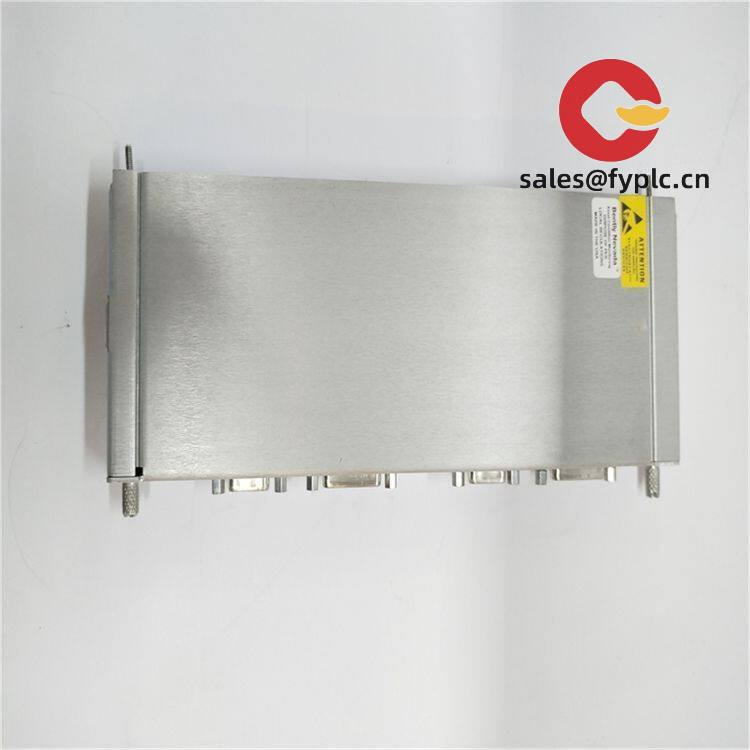

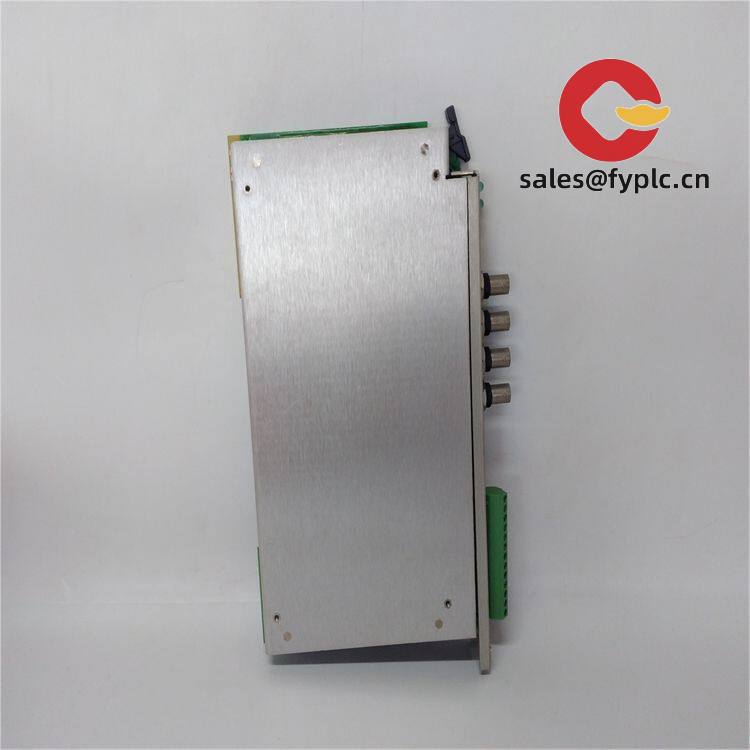

Bently Nevada 3500/15 (129489-01) – Rack Monitor for Machinery Protection Systems

If you’re running a mid-to-large-scale industrial operation with rotating equipment—like turbines, compressors, or pumps—you’ll want reliable monitoring at the rack level. The Bently Nevada 3500/15 monitor, model 129489-01, is designed to serve as the central rack monitor in the 3500 System, managing communication, alarm logic, and system health across multiple modules. From my experience, it’s typically found in oil & gas plants, power generation stations, and heavy manufacturing facilities where uptime and predictive maintenance are mission-critical.

Our Order Placement Process and Guarantees

Warranty: 365 days from date of delivery

Delivery Time: 1 week for in-stock units; no more than one month if backordered

Payment Terms: 50% advance payment, balance due before shipment

Shipping: FedEx, UPS, or DHL express only — fully tracked and insured

Units are tested prior to dispatch and shipped in original packaging when possible.

Key Features

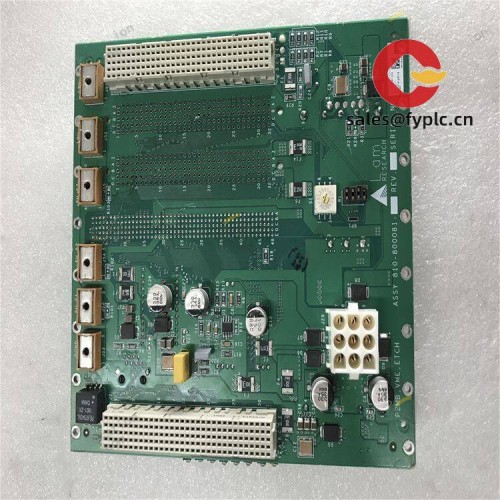

- Central Rack Intelligence: Acts as the brain of the 3500 system, coordinating data flow between input modules (vibration, position, temperature) and control systems.

- Redundant Communication Support: In many cases, users configure dual Modbus RTU or Ethernet ports to maintain connectivity even during network faults.

- Alarm and Event Management: Built-in logic handles trip decisions, event logging, and status reporting — reducing dependency on external PLCs.

- Hot-Swappable Design: You might notice that this module supports online replacement without shutting down the rack, which helps minimize process interruptions.

- Front Panel Diagnostics: LED indicators give immediate visual feedback on power, comms, and fault states — useful during troubleshooting.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Bently Nevada / 3500/15 (129489-01) |

| HS Code | 85371090 – Other boards, panels for electrical machines |

| Power Requirements | Dual 24 VDC inputs (redundant), typical draw: 1.2 A per channel |

| Dimensions & Weight | Standard 19″ rack width, 5U height; approx. 4.8 kg |

| Operating Temperature | 0°C to 70°C (32°F to 158°F) |

| Communication Interfaces | RS-485 (Modbus RTU), optional Ethernet (Modbus TCP/IP) |

| Installation Method | DIN-rail mounted within 3500 rack chassis (e.g., 3500/20 or 3500/22) |

| Signal I/O Types | Digital inputs for keyphasor, relay outputs for alarms/trips, serial comms |

Application Fields

This module is commonly used in environments where continuous condition monitoring is non-negotiable. One thing I appreciate is how often it appears in offshore platforms — where remote diagnostics and high availability matter. It’s also standard in combined-cycle power plants managing steam and gas turbines, refineries monitoring critical compressors, and large pumping stations in water treatment or pipeline operations. The redundancy features make it suitable for safety-critical loops.

Advantages & Value

Procurement teams tend to favor the 3500/15 because it integrates seamlessly with existing Bently Nevada ecosystems. There’s usually less engineering overhead compared to third-party replacements. While not the cheapest option upfront, its long-term reliability and compatibility reduce integration risks and spare part fragmentation. Firmware updates are backward-compatible in most cases, so upgrading doesn’t mean overhauling entire racks. Plus, technical support documentation is extensive — helpful when training new engineers.

Installation & Maintenance

Install in a NEMA 12 or IP54-rated control cabinet with adequate ventilation — heat buildup around the rack can shorten component life. Make sure both power rails are connected for redundancy, and use shielded twisted-pair cables for communication links. Grounding is crucial; improper grounding sometimes leads to noise issues on the RS-485 bus. For maintenance, schedule quarterly checks of LED statuses and annual firmware validation. Calibration isn’t required for the monitor itself, but it should be synchronized with calibration cycles of connected sensor modules.

Quality & Certifications

The 3500/15 meets CE, UL, and CSA standards for industrial control equipment. It complies with RoHS directives and is manufactured under ISO 9001-certified processes. Each unit comes with full traceability and test records. As mentioned earlier, we back every unit with a 365-day warranty covering defects in materials and workmanship — excluding physical damage or misuse.

Reviews

There are no reviews yet.