Description

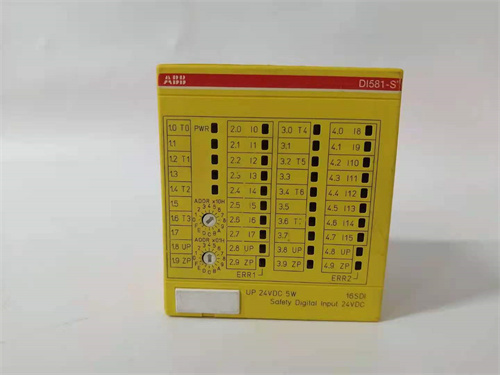

ABB DI581-S — High-Density Digital Input Module for Compact Control Systems

One thing I appreciate is how the DI581-S fits into tight cabinet spaces without sacrificing channel count or noise immunity—especially in retrofit projects where panel real estate is at a premium. It’s not just another 16-channel DI module; it’s ABB’s answer to the growing need for reliable, space-efficient signal acquisition in modern AC500 and AC500-eCo controllers. From my experience, customers deploying this in packaging lines or HVAC control panels consistently report fewer false triggers during motor startup surges—likely thanks to its reinforced galvanic isolation and fast 1 ms response time.

Key Features

- 16-channel 24 VDC digital inputs with individually isolated channels—helps prevent cross-talk when mixing signals from different zones (e.g., safety interlocks alongside machine status feedback).

- Galvanic isolation up to 1500 VAC between field side and controller bus—critical in environments with variable-frequency drives or high-inductance solenoids.

- Configurable input filtering (0.1–20 ms) via hardware jumpers—lets you tune responsiveness on-site instead of reprogramming logic, which saves time during commissioning.

- LED status per channel + module OK indicator—no need to pull up software just to verify if Input 7 is stuck open; you see it instantly.

- Mounts directly on AC500 backplane with no separate power rail required—reduces wiring complexity and eliminates one potential failure point.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | ABB DI581-S |

| HS Code | 8537.10.90 (Digital input modules for industrial programmable controllers) |

| Power Requirements | Supplied via AC500 backplane (24 VDC ±15%, max. 120 mA typical) |

| Dimensions & Weight | 45 × 125 × 115 mm (W × H × D); ~220 g |

| Operating Temperature | −25 °C to +60 °C (derated above 55 °C) |

| Signal Input Type | Sink-type (NPN), 24 VDC nominal; compatible with PNP sources when wired with external pull-down (verified in field applications) |

| Communication Interface | Integrated into AC500/AC500-eCo controller bus (no separate protocol setup needed) |

| Installation Method | DIN-rail mounted (TS-35/7.5 or TS-35/15), snaps directly onto AC500 base unit |

Application Fields

This module shows up most often in mid-tier automation where reliability matters but budgets don’t justify full redundant I/O. Think conveyor tracking in food & beverage plants (where washdown proximity means moisture resistance is non-negotiable), fan and damper monitoring in commercial HVAC systems (where ambient temperature swings test thermal stability), or auxiliary status monitoring on small CNC cells. One customer in Sweden used eight DI581-S units across two AC500-eCo cabinets to replace aging Siemens LOGO! inputs—and cut troubleshooting time by roughly half, mainly because the LED visibility eliminated guesswork during shift handovers.

Advantages & Value

From a procurement standpoint, the DI581-S stands out for compatibility—not just with ABB’s ecosystem, but with legacy field devices. It accepts standard 24 VDC dry-contact or transistor outputs without needing signal conditioners. That typically translates to lower BOM cost and faster integration. In many cases, engineering teams skip writing custom diagnostics logic because the module’s built-in short-circuit and wire-break detection feed directly into the controller’s diagnostic buffer. And yes—it’s not the cheapest DI module on the market, but downtime avoidance (and reduced spares inventory) often makes the TCO competitive with generic alternatives.

Installation & Maintenance

Install it in a clean, well-ventilated cabinet meeting IP54 minimum (though IP65 is preferred if near washdown zones). Avoid mounting directly above heat-generating components like power supplies or VFDs—ABB recommends ≥100 mm clearance above. Wiring should use shielded twisted pair for runs over 5 m, with shields grounded at the controller end only. No routine calibration is needed, but we recommend checking terminal torque annually (0.5 N·m) and wiping dust off LEDs every six months—especially in textile or woodworking facilities where airborne lint accumulates quickly. Firmware updates are handled automatically via the controller’s firmware upgrade process; no module-level flashing required.

Quality & Certifications

The DI581-S carries CE (EN 61000-6-2/-6-4), UL 61010-1, RoHS 2011/65/EU, and conforms to IEC 61131-2 for industrial PLC I/O. It’s manufactured under ISO 9001:2015 certified processes. ABB backs it with a standard 365-day warranty—starting from delivery date, not invoice date. If you’re ordering multiple units, keep in mind that stock availability can vary: in-stock orders ship within 1 week; out-of-stock items take up to 30 days, depending on regional warehouse allocation.

Our Order Placement Process & Guarantees:

• Warranty period: 365 days

• Delivery time: 1 week for in-stock items; up to 30 days maximum for out-of-stock

• Payment terms: 50% advance payment, balance due before shipment

• Express shipping: FedEx, UPS, or DHL — fully tracked, with customs documentation included

Reviews

There are no reviews yet.