Description

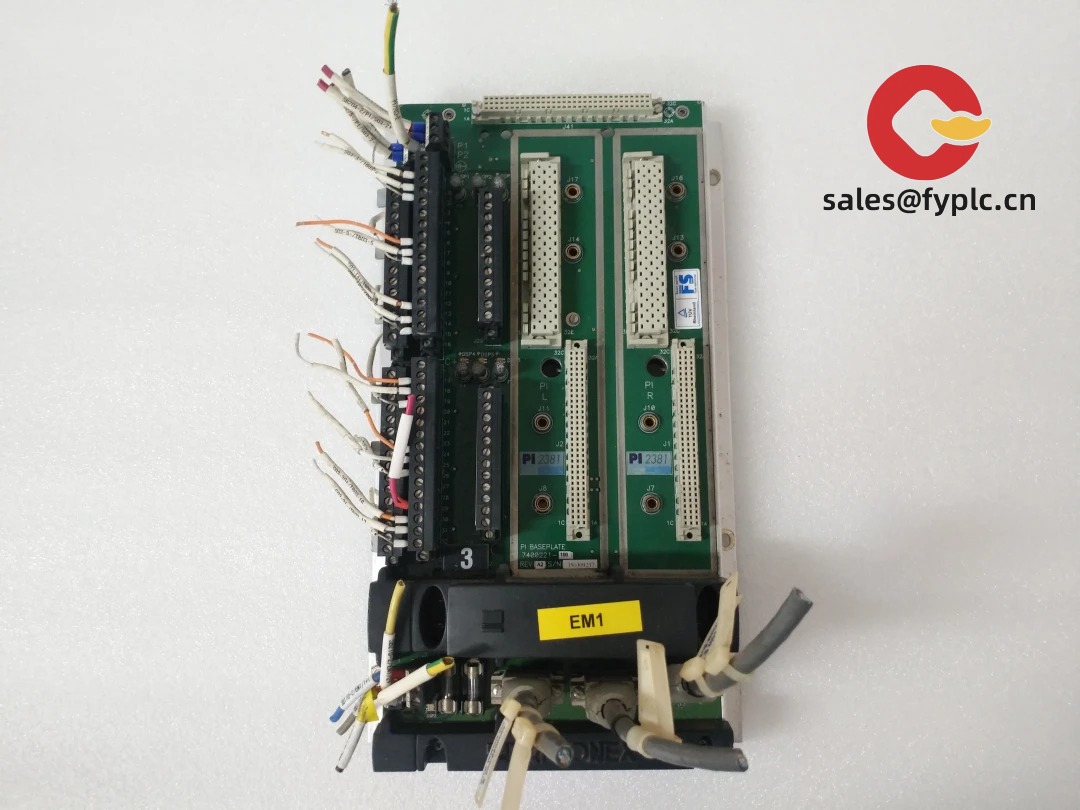

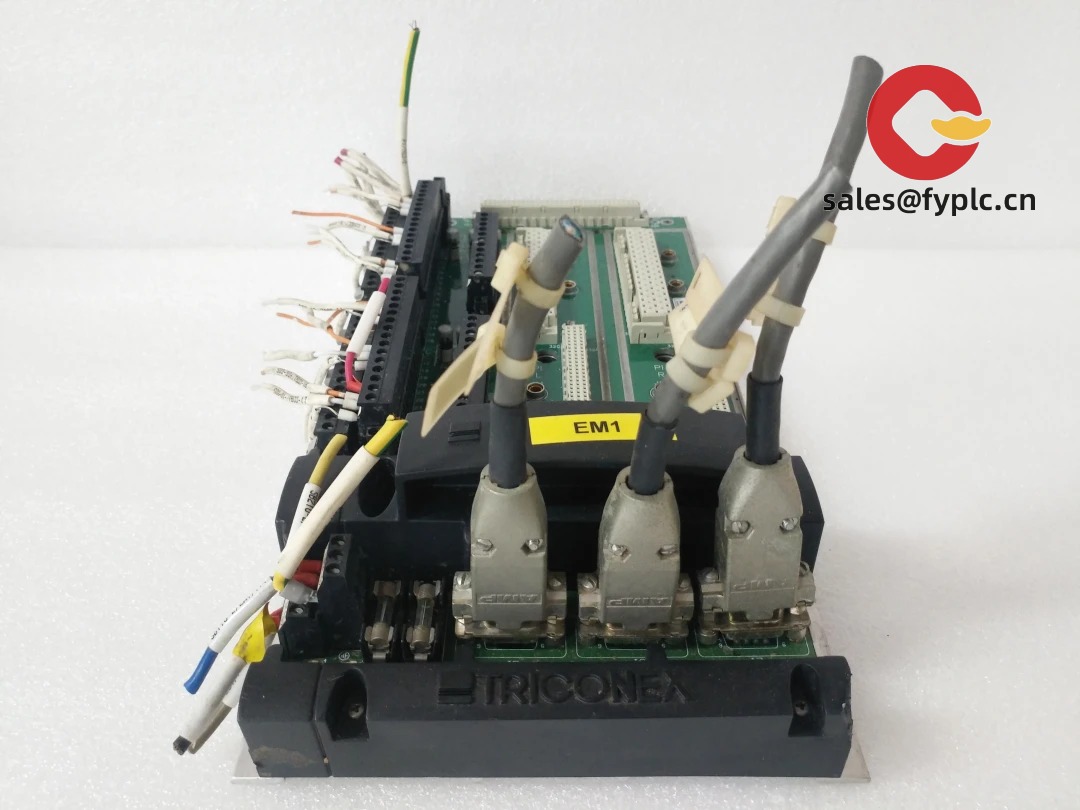

Triconex 2381 Triple Modular Redundant (TMR) Input Module

Used in safety-critical process environments—think offshore platforms, ethylene crackers, or hydrogen production units—the Triconex 2381 is the workhorse analog input module for the Tricon system. It’s not just another I/O card; it’s the first line of defense when measuring pressure, temperature, or flow signals that feed directly into SIL-2 or SIL-3 shutdown logic. From my experience supporting refineries in the Gulf Coast, this module shows up most often in compressor surge protection loops and burner management systems—places where a single-point failure isn’t an option.

Key Features

- TMR architecture with hot-swappable voting: All three independent channels condition, digitize, and vote on each analog input in real time—no software intervention needed. You might notice that field wiring stays live during replacement, which cuts downtime significantly.

- Configurable 4–20 mA or 0–20 mA inputs (with HART support): Works with standard loop-powered transmitters—and yes, it passes HART bursts through to the DCS side when used in hybrid configurations. In many cases, engineers reuse existing transmitter infrastructure without rewiring.

- Integrated open-circuit and over-range diagnostics: Flags broken wires or sensor saturation before they cascade into spurious trips. One customer in Alberta told us it cut nuisance shutdowns by ~40% after replacing legacy non-voting cards.

- Galvanic isolation up to 1500 VRMS: Helps suppress ground loops in electrically noisy areas—like near VFDs or large motor starters—without needing external isolators.

- Backplane-powered, no auxiliary supply required: Simplifies cabinet layout. No extra 24 VDC distribution needed, which saves panel space and reduces point-of-failure count.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Triconex 2381 |

| HS Code | 8537.10.90 (Automatic control or regulation instruments & apparatus, for industrial use) |

| Power Requirements | Supplied via Tricon backplane (5 VDC ±5%, 12 VDC ±5%); typical draw: 1.2 A @ 5 V, 0.3 A @ 12 V |

| Dimensions & Weight | 218 mm × 112 mm × 55 mm (W × H × D); ~520 g |

| Operating Temperature | 0 °C to +60 °C (derated above 45 °C) |

| Signal Input Types | 16-channel, isolated 4–20 mA or 0–20 mA (configurable per channel); supports HART transparent mode |

| Communication Interfaces | Native integration via Triconex backplane only (no Ethernet/Modbus native); data accessible via TriStation 1131 or Triconex DCS gateways |

| Installation Method | DIN-rail mounted inside Tricon main or expansion chassis (e.g., TRICONEX-3009, -3012); requires compatible power supply and diagnostic module |

Application Fields

The 2381 typically appears where analog integrity directly impacts personnel safety or asset protection: emergency shutdown (ESD) systems in LNG terminals, fire & gas (F&G) detection loops at chemical plants, turbine overspeed monitoring in combined-cycle power stations, and reactor coolant level sensing in nuclear support facilities. It’s rarely used in basic automation—it’s reserved for functions defined in IEC 61511 as SIFs (Safety Instrumented Functions). One Midwest petrochemical site recently deployed it to monitor jacket water temperature across six parallel reactors—replacing three separate non-redundant cards and cutting spare parts SKUs by 60%.

Advantages & Value

If you’re evaluating replacements or expanding an existing Tricon system, the 2381 delivers tangible procurement advantages. First, its backward compatibility with Tricon versions 7.x–11.x means no forced firmware upgrades across your entire rack—unlike some newer modules that require full system revalidation. Second, because it’s manufactured under Schneider Electric’s long-standing Triconex quality system (not outsourced), lead times are more predictable: in-stock units ship in under a week, and even custom-configured orders rarely exceed four weeks. Third, while not the lowest-cost analog input on paper, its TMR-native design eliminates the need for external voting logic or dual-channel redundancy schemes—so total installed cost tends to be lower than patching together competing solutions. And yes, it ships with full traceable calibration data—not just “as-tested” certs.

Installation & Maintenance

Mount only in Schneider-certified Tricon chassis with proper grounding (per ISA-RP12.6). Cabinet ambient must stay below 60 °C, with ≥100 mm clearance above/below the module for convection cooling—don’t stack tightly next to high-wattage power supplies. Wiring should use twisted-pair, shielded cable (Belden 8761 or equivalent), with shields grounded at the module end only. Avoid routing near AC mains or VFD outputs unless separated by ≥300 mm or a grounded metal barrier. For maintenance: verify zero/span drift annually using a certified calibrator (Fluke 754 recommended); clean dust filters every 6 months if installed in dusty environments; and apply firmware updates only during scheduled outages—Triconex advises against updating mid-campaign unless addressing a documented safety bulletin. Note: hot-swap is supported, but always confirm the system is in “Maintenance Mode” via TriStation before removal.

Quality & Certifications

Certified to IEC 61508 SIL-3 (hardware fault tolerance = 2), UL 61010-1, CSA C22.2 No. 61010-1, ATEX II 2G Ex ia IIC T4 Ga, IECEx ia IIC T4 Ga, and RoHS compliant. Backed by a standard 365-day warranty from date of shipment—covers defects in materials and workmanship, including field-replaceable components like terminal blocks and fuses. Technical support includes free access to TriStation configuration templates, diagnostic logs interpretation, and priority response (<4 business hours) for critical safety-related queries. Firmware patches and security advisories are distributed via Schneider’s official Product Alert Portal—not third-party forums.

Our Order Placement Process & Guarantees:

• Warranty: 365 days from shipment

• Delivery: 1 week for in-stock units; ≤4 weeks maximum (even for configured variants)

• Payment: 50% advance, balance before dispatch

• Shipping: FedEx, UPS, or DHL Express — fully tracked, with customs documentation handled

Reviews

There are no reviews yet.