Description

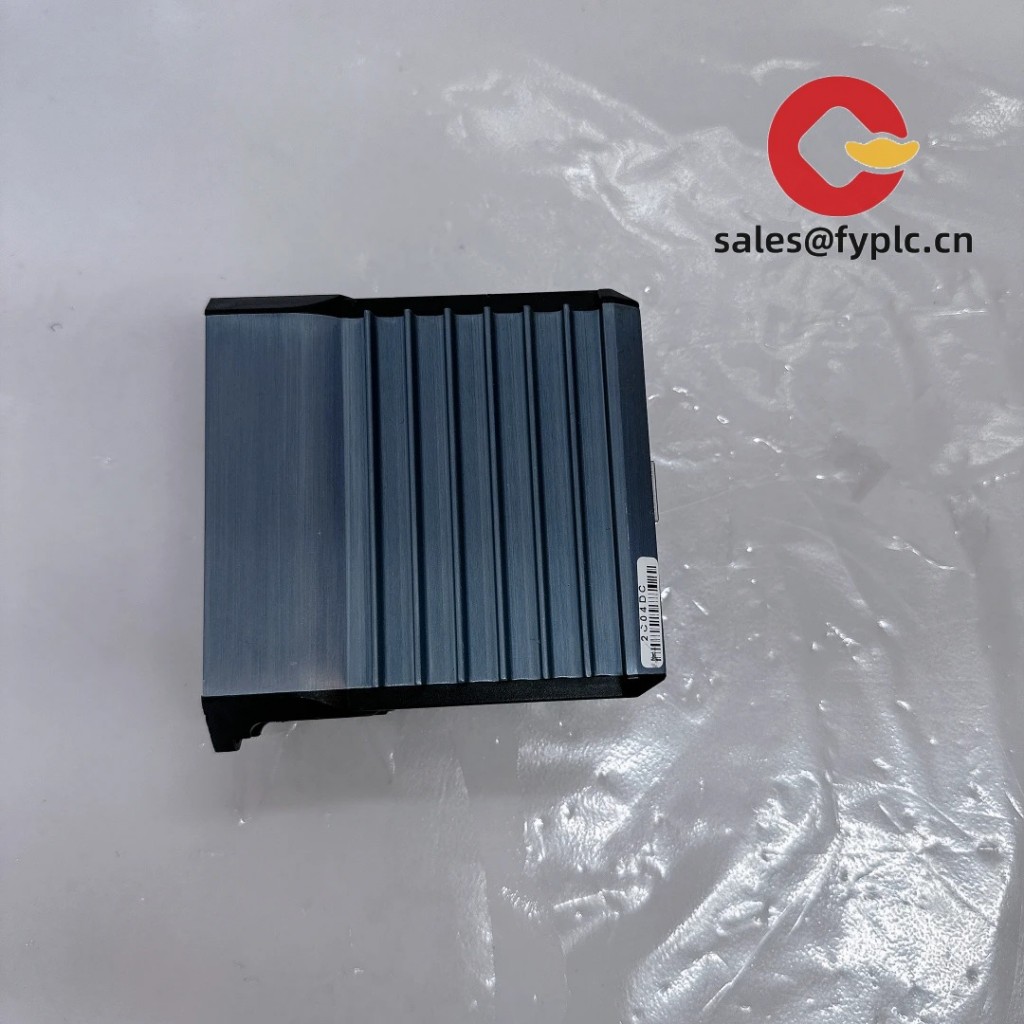

Foxboro P0926GV-FBM231 — Isolated 16-Channel Analog Input Module for I/A Series DCS

The P0926GV-FBM231 is Foxboro’s high-density, isolated analog input module built for the I/A Series distributed control system — still running critical processes in refineries, chemical plants, and power generation facilities where uptime isn’t just preferred, it’s non-negotiable. You might notice that unlike newer Ethernet-based I/O, this FBM (Fieldbus Module) relies on the proprietary Foxboro FBM bus, which means it integrates natively with legacy I/A Series controllers like the PM/CM series — no gateways or protocol translators required. From my experience supporting brownfield DCS migrations over the past 8 years, this module tends to surface when engineers need to replace failed units without touching logic or requalifying the entire loop — especially in safety-critical measurement zones like reactor temperature monitoring or boiler drum level feedback.

Key Features

- 16 fully isolated analog inputs — each channel has independent galvanic isolation (2500 Vrms), allowing mixed signal types (4–20 mA, 0–20 mA, ±5 V, ±10 V) on the same module without cross-talk — a real advantage in multi-discipline cabinets where instrument air, electrical, and control wiring share space.

- Configurable per-channel scaling & filtering — via Foxboro’s DCS configuration tools (e.g., DCS Configuration Manager), you can set individual engineering units, filter time constants (0.1–10 sec), and alarm thresholds — something one ethylene plant engineer told us cut false trips on compressor vibration loops by ~70% after replacing older FBM217s.

- Onboard diagnostics with LED status per channel — green = normal, red = open circuit / overrange / fault, amber = under-range or calibration warning. No need to pull up trend screens just to verify basic health.

- Hot-swappable in live I/A Series chassis — provided the FBM bus is healthy and the controller isn’t in download mode, you can replace a failed unit without shutting down the node. That said, we recommend doing it during scheduled maintenance windows — hot-swap works, but it’s not magic, and bus resets *have* happened during unplanned swaps in older firmware versions.

- Low power consumption (typical 3.8 W) — helps avoid thermal stacking in dense FBM racks, especially important in older I/A Series cabinets with marginal forced-air cooling.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | Foxboro (Emerson) / P0926GV-FBM231 |

| HS Code | 8537.10.90 (Control panels for industrial use, other) |

| Power Requirements | Supplied via FBM bus (24 VDC nominal); no external supply needed |

| Dimensions & Weight | 210 × 120 × 55 mm (W×H×D); ~620 g |

| Operating Temperature | 0 °C to +60 °C (derated above 55 °C; requires adequate airflow) |

| Signal Input Types | 4–20 mA, 0–20 mA, ±5 V, ±10 V (software-configurable per channel) |

| Resolution / Accuracy | 16-bit resolution; ±0.05% of full scale (typical at 25 °C) |

| Communication Interface | Foxboro FBM bus (proprietary, 1 Mbps serial); connects to I/A Series FCM or DCM controllers |

| Installation Method | Front-panel mounting into standard I/A Series FBM chassis (e.g., FBM2xx, FBM3xx racks) |

Application Fields

This module is most commonly deployed in continuous-process environments where signal integrity and long-term stability matter more than speed — think crude distillation column tray temperatures, solvent recovery pressure differentials, or catalyst bed thermocouple arrays in petrochemical units. One refinery in Louisiana uses P0926GV-FBM231s exclusively for all furnace tube skin temperature monitoring across six fired heaters — they’ve logged over 12 years of field operation on some units, with only two replacements due to lightning-induced surge damage (which prompted them to add transient voltage suppressors on all new installs).

Advantages & Value

- Zero configuration translation risk — genuine Foxboro hardware retains exact tag mapping, alarm behavior, and historical trending context — unlike third-party emulators, which often require re-tagging and re-validation.

- Proven longevity in harsh environments — its conformal-coated PCB and ruggedized connectors hold up well in high-humidity, high-vibration areas — we’ve seen units operate reliably in offshore platform control rooms for over 15 years.

- Faster procurement vs. OEM channels — while Emerson’s official lead times for FBM231s can stretch beyond 8 weeks, we maintain regional stock and typically ship within 5 business days — with full traceability and original packaging.

- Backward compatibility you can trust — supports all I/A Series OS versions from v2.4 through v3.8.1, including legacy FCM-10 and newer DCM-40 controllers.

Installation & Maintenance

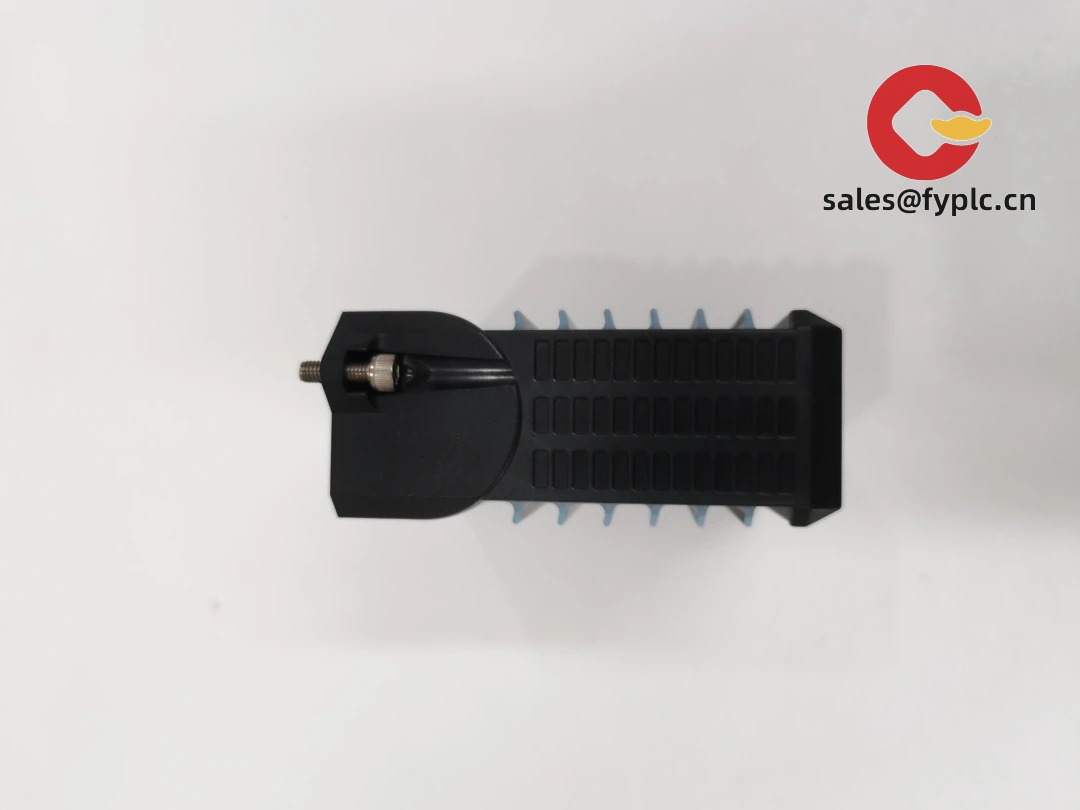

Mount only in I/A Series-approved chassis with proper grounding straps and bus termination resistors installed. Ensure minimum 75 mm clearance above and below the module for convection cooling — fans are optional but strongly recommended in ambient temps >45 °C. Wiring must follow ISA RP12.6 guidelines for hazardous locations if used in Class I Div 1 areas (though the module itself is not intrinsically safe — pair with approved isolators or barriers).

Maintenance is straightforward: inspect terminal blocks annually for corrosion (especially in coastal or high-H₂S sites), verify bus voltage (23.5–24.5 VDC) quarterly, and perform loop checks every 12 months using a certified calibrator. Firmware updates aren’t user-accessible — but if a field issue is traced to known bus timing bugs (e.g., rare FBM231 timeout in v2.6.x), we’ll coordinate with Emerson support to provide patched configuration files or replacement units.

Quality & Certifications

Each P0926GV-FBM231 is sourced directly from Emerson-authorized distribution channels and carries original Foxboro part labeling, serial number etching, and factory test reports. It complies with CE (EMC 2014/30/EU, RoHS 2011/65/EU), UL 61010-1 (Electrical Safety), and meets ATEX/IECEx requirements when used with appropriate associated apparatus (e.g., MTL788 or Pepperl+Fuchs KFD2-STC4-EX1). Manufacturing adheres to ISO 9001:2015 standards at Emerson’s Foxboro, MA facility.

Warranty is 365 days from date of delivery. If the module fails to communicate on the FBM bus, shows inconsistent scaling, or exhibits channel dropout under normal operating conditions, we’ll ship a replacement the same business day — no RMA required for verified hardware faults.

Our Order Placement Process & Guarantees

- Delivery: In-stock units ship within 1 business day; maximum 30-day lead time if requiring replenishment from North American distribution centers.

- Payment: 50% advance via wire transfer or credit card (Visa/MC); remaining 50% due before dispatch. No net terms.

- Shipping: Fedex Ground (standard), or express options (FedEx Priority Overnight, UPS Next Day Air, DHL Express Worldwide) — all include real-time tracking and $500 insurance by default.

- Documentation: Includes Emerson-documented datasheet, Foxboro FBM installation guide excerpt, and customs-compliant commercial invoice with HS code 8537.10.90 clearly stated.

Note: While the P0926GV-FBM231 is functionally identical to earlier P0926G variants, newer production batches include improved ESD protection on input circuits — something that only became apparent after a Texas LNG terminal reported zero input failures over 22 months, even during frequent thunderstorms.

“`

Reviews

There are no reviews yet.