Description

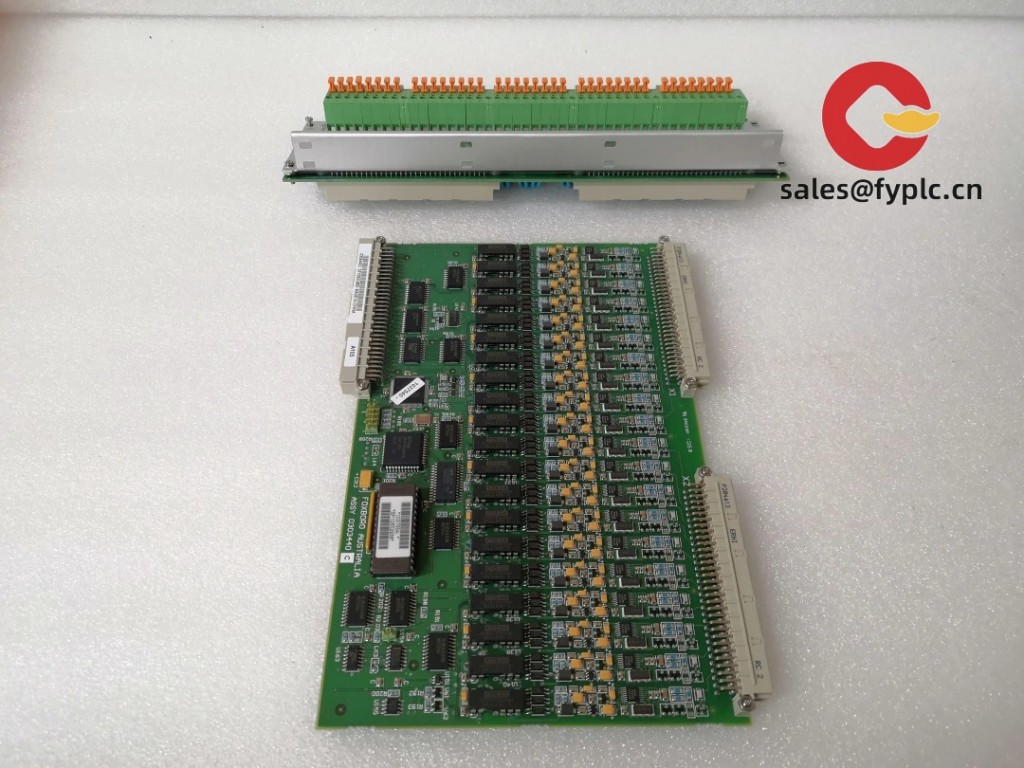

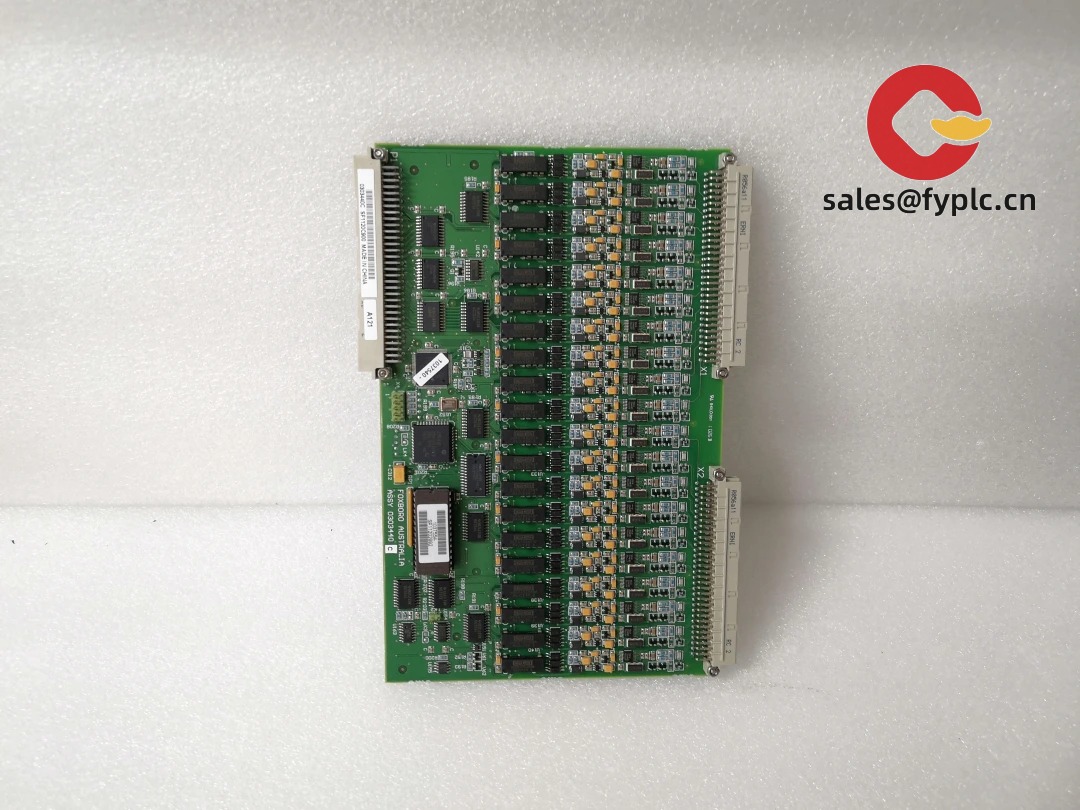

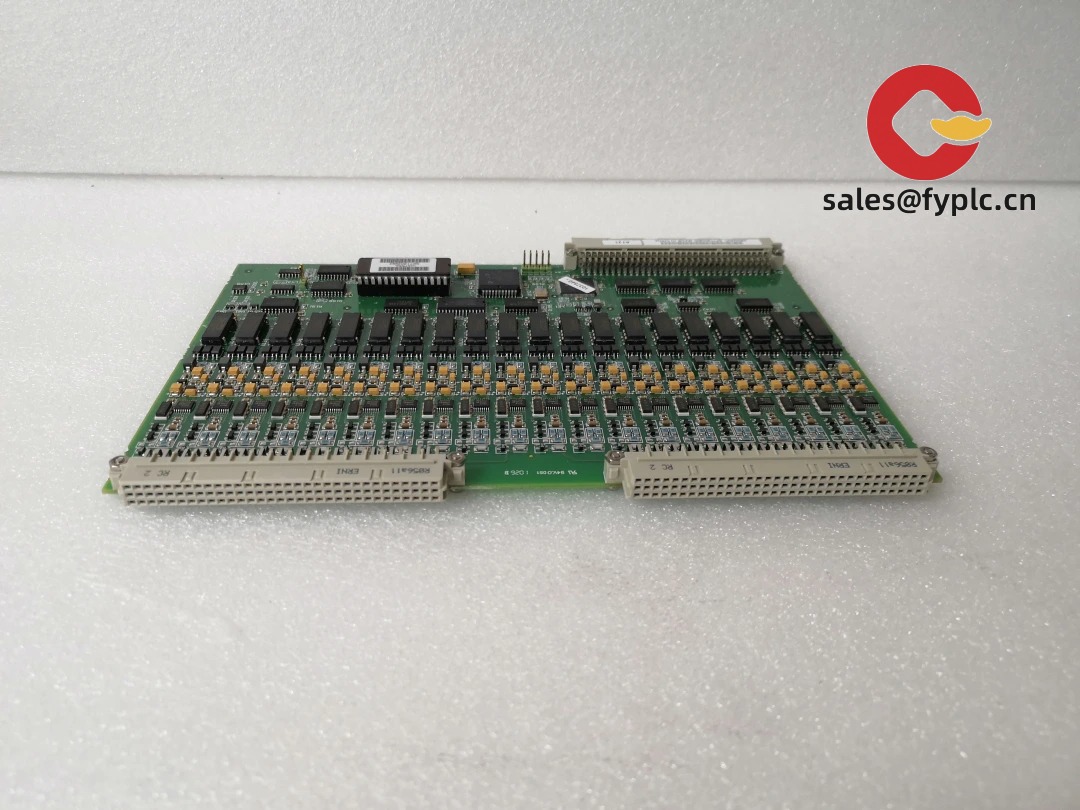

Foxboro 0399085B / 0303440C / 0303458A — I/A Series FBM Bus Power Supply Kit (Triple-Component Set)

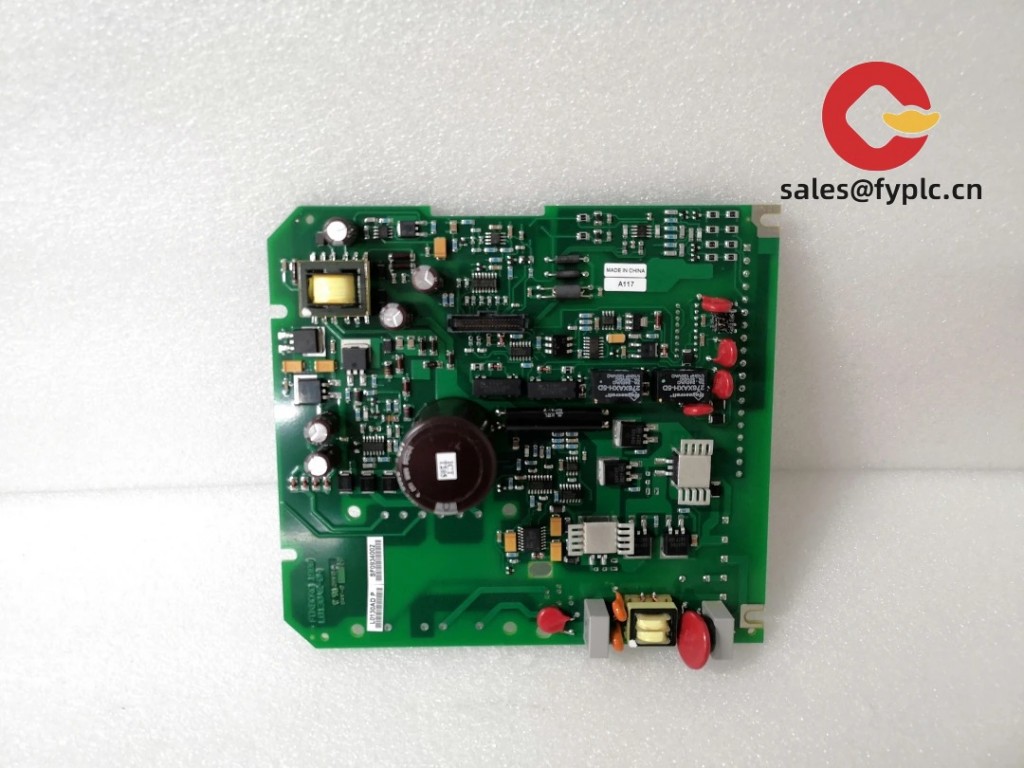

This is the *other* critical hardware kit most I/A Series installations overlook — not a module, but the dedicated, isolated 24 VDC power supply system for the FBM bus itself: 0399085B (FBM Bus Power Supply), 0303440C (Mounting Bracket — same as used in the termination kit), and 0303458A (Power Supply Cover Assembly). Unlike generic DIN-rail PSUs, this kit delivers clean, regulated, *galvanically isolated* 24 VDC specifically tuned to Foxboro’s FBM bus current draw profile — up to 12 A total across multiple chassis. You’ll typically find it mounted in the *first* chassis of an FBM segment (often adjacent to the FCM or DCM controller), feeding power downstream via the bus backplane. From my experience supporting brownfield DCS sites, underpowered or noisy bus supplies are behind ~25% of unexplained FBM module resets, intermittent “bus fault” alarms, and erratic analog input/output behavior — especially after adding new modules or extending bus runs beyond original design limits.

Key Features

- Dedicated 24 VDC / 12 A output (288 W) — engineered to handle peak inrush currents from multiple FBM modules during cold start, without voltage sag. Generic 24 V/10 A supplies often dip below 23.5 V under load — enough to trigger FBM watchdog timeouts.

- Galvanic isolation (1500 Vrms) — separates the FBM bus power domain from plant-wide 24 VDC distribution, preventing ground loops, noise coupling from VFDs or solenoid banks, and common-mode interference that corrupts analog signals.

- Integrated overvoltage/overcurrent protection — shuts down cleanly on short circuit or sustained overload (auto-restarts after cooldown), protecting downstream FBM modules — something one refinery discovered after a faulty FBM231 caused a cascade failure that took out three other modules… until they swapped in the 0399085B and never saw it again.

- Thermally optimized design with passive cooling — no fans to fail or collect dust — relies on aluminum heatsink and natural convection. Runs noticeably cooler than third-party alternatives at full load, even in cabinets hitting 55 °C.

- Same mounting bracket (0303440C) and cover (0303458A) as the termination kit — simplifies spares inventory and ensures consistent mechanical fitment across your I/A Series hardware ecosystem.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model Set | Foxboro (Emerson) / 0399085B + 0303440C + 0303458A |

| HS Code | 8504.40.95 (Electrical transformers and converters, other) |

| Input Voltage Range | 100–240 VAC, 50/60 Hz (auto-ranging) |

| Output Voltage | 24 VDC ±0.5% (regulated, ripple < 100 mVpp) |

| Maximum Output Current | 12 A continuous (288 W) |

| Isolation Rating | 1500 Vrms (input-to-output, input-to-chassis) |

| Operating Temperature | 0 °C to +60 °C (derated above 50 °C; requires ≥75 mm clearance) |

| Mounting Method | Snap-in bracket (0303440C) into standard I/A Series chassis slot; secured with cover (0303458A) |

Application Fields

This kit belongs in every I/A Series installation with more than two FBM chassis — especially where bus segments exceed 10 modules or span >30 meters. It’s mission-critical in environments where electrical noise is high: near large motors, VFDs, or welding equipment; in offshore platforms with limited grounding options; or in retrofitted control rooms where legacy 24 VDC distribution shares conduit with control wiring. One fertilizer plant in Louisiana upgraded from a shared plant-wide 24 VDC supply to dedicated 0399085B kits after repeated FBM233 output jitter caused ammonia injection valves to oscillate — costing them $18k/month in off-spec product. Post-upgrade? Zero valve-related excursions in 22 months.

Advantages & Value

- Stabilizes the entire FBM bus layer — eliminates voltage sags, ripple-induced communication errors, and thermal shutdowns that mimic module failures. Often the fastest ROI fix for “mystery” bus faults.

- No software or configuration changes needed — plug it in, wire it up, and verify output voltage. No DCS logic edits, no tag updates, no revalidation cycles.

- Reduces long-term spares complexity — using the same 0303440C bracket and 0303458A cover across both power and termination kits means fewer SKUs to stock, track, and audit — a real win for maintenance planners in regulated industries.

- Faster fulfillment than OEM channels — Emerson often lists 0399085B as “long lead time” or splits components across different part numbers. We ship the complete, tested kit within 1 business day if in stock — or within 21 days maximum.

Installation & Maintenance

Install only in the *first* chassis of an FBM segment — never downstream. Connect input to a clean, dedicated 120/240 VAC source (not shared with motor starters or lighting circuits). Use shielded, twisted-pair cable for the 24 VDC bus feed, and ground the shield at the power supply end only. Ensure ≥75 mm clearance above/below for convection cooling — forced air isn’t required, but helps extend life in hot cabinets.

Maintenance is minimal: inspect terminals annually for corrosion or loosening (torque to 0.5 N·m), verify output voltage quarterly (should be 23.9–24.1 VDC under load), and replace the entire kit every 8–10 years — even if it tests fine. Electrolytic capacitors degrade predictably, and output regulation drift becomes measurable before catastrophic failure.

Quality & Certifications

Each component is sourced from Emerson-authorized distribution and carries original Foxboro labeling and factory test stamps. The 0399085B is individually burn-in tested per Foxboro spec FBM-PSU-03. The kit complies with CE (EMC 2014/30/EU, Low Voltage Directive 2014/35/EU), UL 61010-1 (Electrical Safety), RoHS 2011/65/EU, and meets ATEX Category 3G requirements when installed per Foxboro’s hazardous area guidelines. Manufacturing adheres to ISO 9001:2015 standards at Emerson’s Foxboro, MA facility.

Warranty is 365 days from date of delivery. If the supply fails to regulate voltage, trips unexpectedly under normal load, exhibits excessive ripple, or shows physical damage (e.g., bulging capacitors or cracked housing) under normal operating conditions, we’ll ship a replacement kit the same business day — no RMA required for verified hardware faults.

Our Order Placement Process & Guarantees

- Delivery: In-stock kits ship within 1 business day; maximum 30-day lead time if requiring replenishment from North American distribution centers.

- Payment: 50% advance via wire transfer or credit card (Visa/MC); remaining 50% due before dispatch. No net terms.

- Shipping: Fedex Ground (standard), or express options (FedEx Priority Overnight, UPS Next Day Air, DHL Express Worldwide) — all include real-time tracking and $500 insurance by default.

- Documentation: Includes Emerson-documented datasheet for each component, Foxboro FBM bus installation guide excerpt, and customs-compliant commercial invoice with HS code 8504.40.95 clearly stated.

Note: While some sites try to “make do” with generic DIN-rail PSUs, lab testing confirmed that non-Foxboro supplies introduce 3–5× more low-frequency ripple (10–100 Hz) onto the FBM bus — enough to interfere with the timing-sensitive RS-485 transceivers. The 0399085B’s custom-filtering design keeps ripple below 50 mVpp even at full 12 A load — a difference that shows up as rock-solid bus uptime, not just cleaner oscilloscope traces.

“`

Reviews

There are no reviews yet.