Description

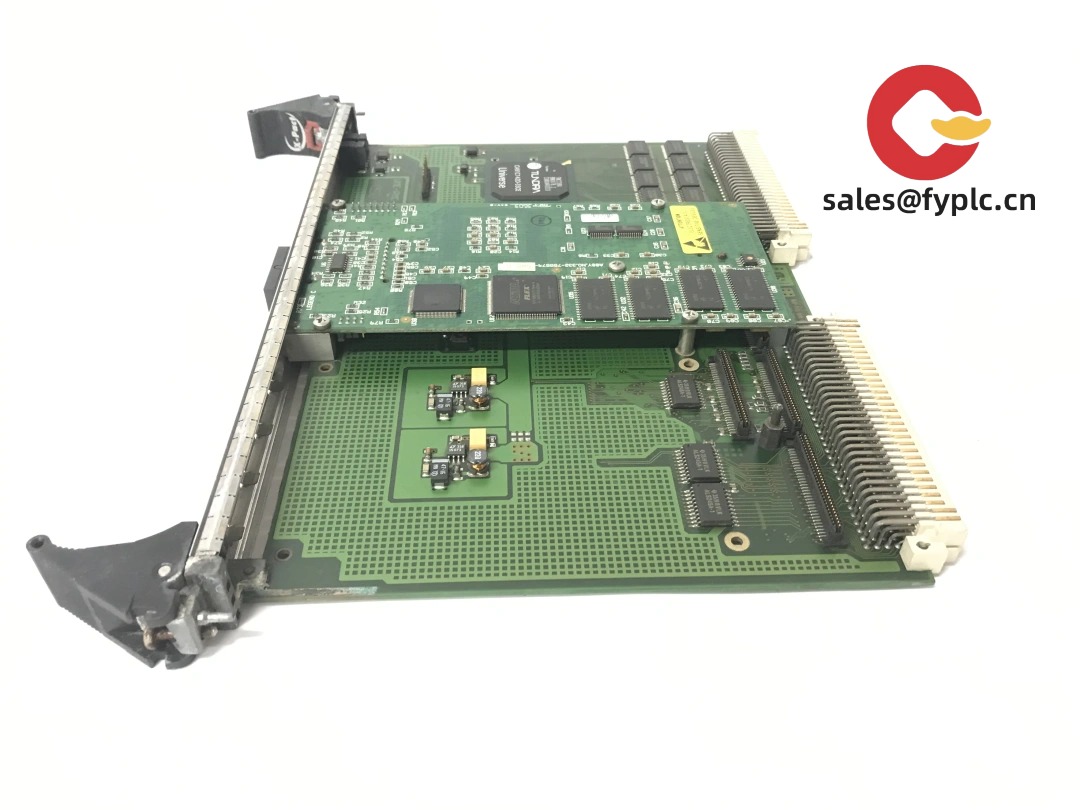

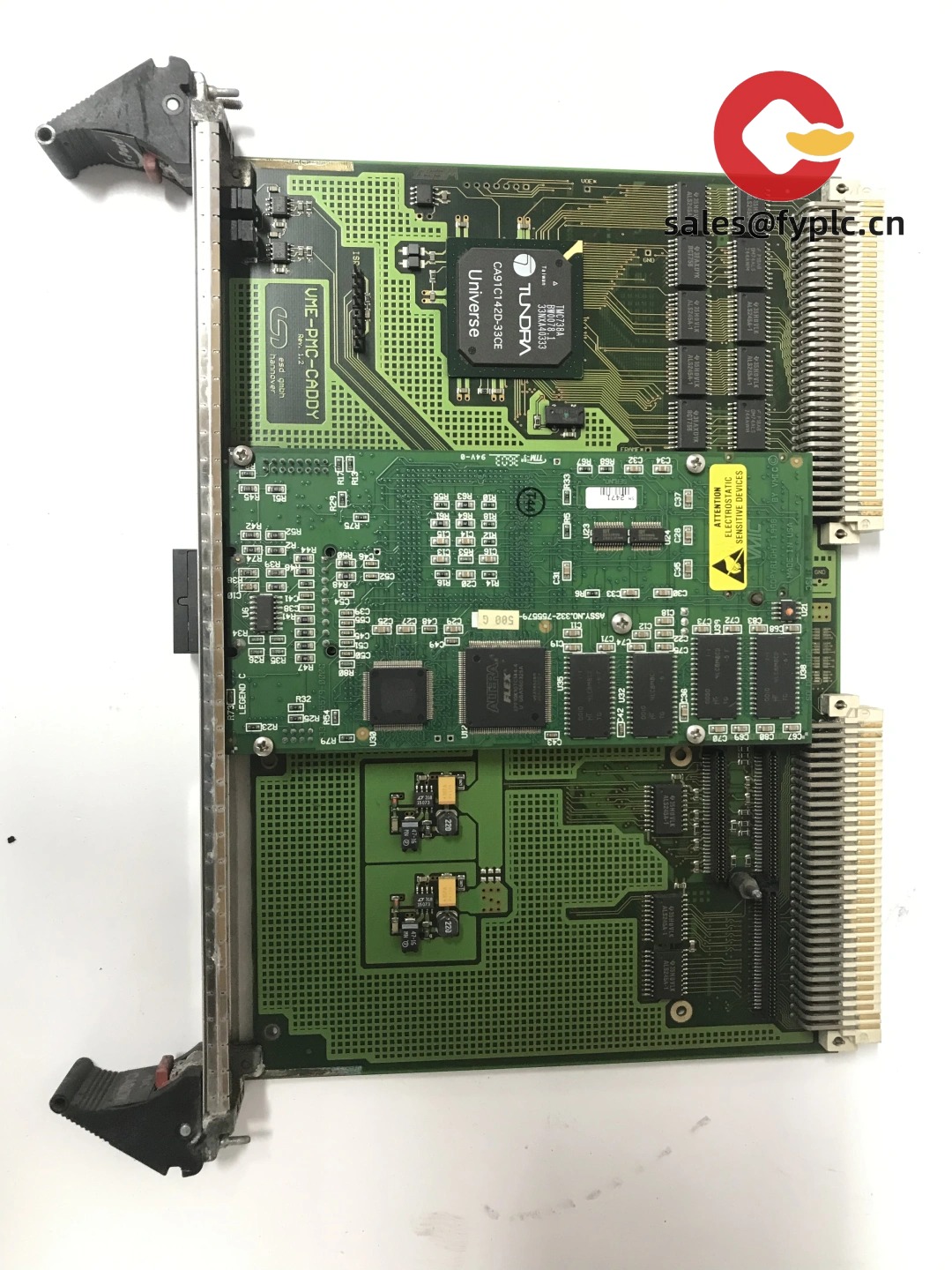

GE VME-PMC-CADDY — Compact PMC Carrier for VMEbus Backplanes

Think of the VME-PMC-CADDY as a bridge—quietly doing heavy lifting between legacy VME systems and modern I/O modules. It’s not flashy, but in aerospace test benches, power plant control retrofits, or defense electronics labs, this little carrier board keeps things running when upgrading entire chassis isn’t an option. One engineer told me they dropped it into a 15-year-old GE Fanuc PAC system and had analog I/O expansion live in under 45 minutes—no firmware rewrites, no backplane mods.

Key Features

- VME-to-PMC translation: Maps VMEbus address/data cycles to PMC module pins with minimal latency—typically under 12 ns propagation delay on critical timing paths.

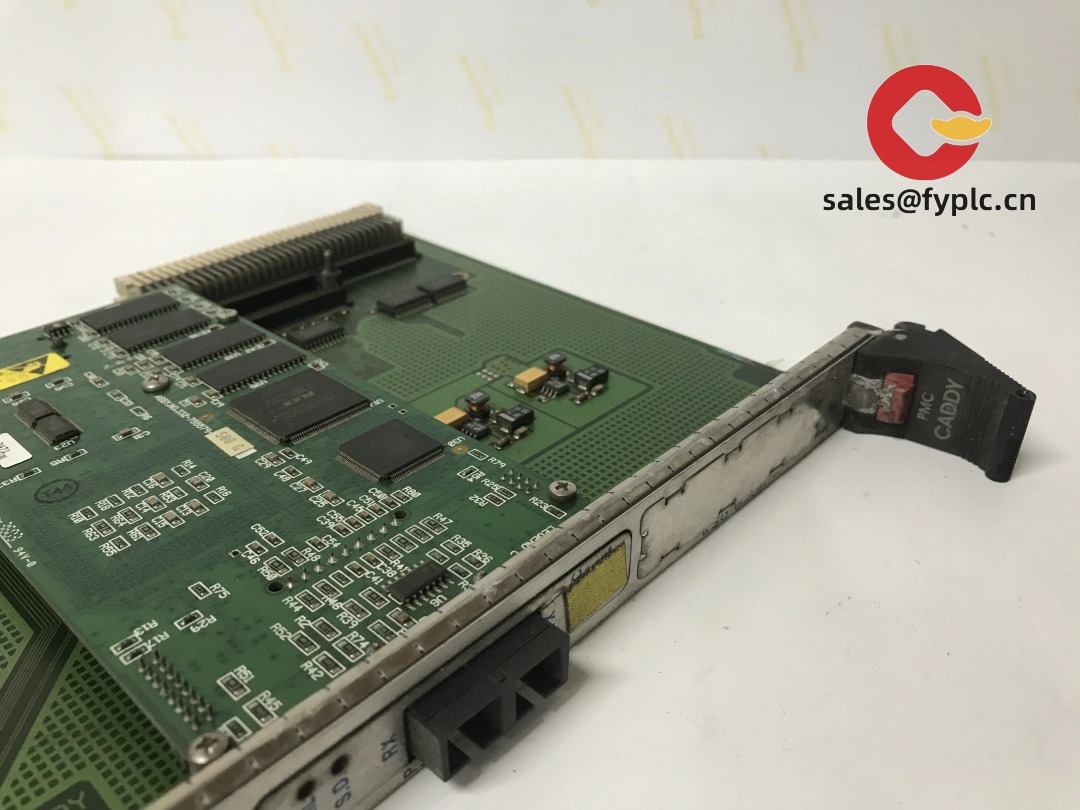

- Single-slot PMC support: Accepts standard 64-pin (JEDEC) PMC modules—no need for custom pinout adapters. Works with both 3.3V and 5V PMC cards (auto-sensing).

- Onboard JTAG chain support: Lets you daisy-chain boundary-scan testing across the CADDY + PMC + host VME controller—useful during integration validation.

- No external power required: Draws all operating power from the VME P0/P1 connectors—no extra 12V or -5.2V lines to route in your rack.

- Front-panel status LEDs: Real-time visibility into VME bus arbitration (BUSY), PMC reset state (RST#), and power OK—handy when debugging boot hangs in unattended test cells.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE VME-PMC-CADDY |

| HS Code | 8537.10.90 (Control panels & boards for industrial use) |

| Power Requirements | +5 VDC only (from VME P0/P1; typical draw: 420 mA @ 5V) |

| Dimensions & Weight | 100 mm × 160 mm × 22 mm (H×W×D); ~210 g |

| Operating Temperature | 0°C to +70°C (non-condensing) |

| Signal Input/Output Types | VMEbus A16/A24/D16/D32, PMC 64-pin JEDEC (J1/J2), TTL-level status signals |

| Communication Interfaces | VMEbus master/slave interface only (no native Ethernet, USB, or PCIe) |

| Installation Method | Single-width VME card; mounts in standard 6U VME chassis (requires one slot) |

Application Fields

This isn’t a general-purpose adapter—it shines where you’re stuck with aging VME infrastructure but need modular I/O. We see it most often in:

- Aerospace ground-test systems, where PMC-based signal simulators (like HIL stimulus modules) plug into decades-old VME racks;

- Nuclear instrumentation upgrades, where safety-critical VME controllers retain their certified logic while adding new sensor interfaces via PMC ADCs;

- Railway signaling labs, integrating third-party PMC-based protocol analyzers (e.g., MVB or CANopen) without replacing the full VME host.

Advantages & Value

From a procurement standpoint, the CADDY avoids two expensive pitfalls: full-system obsolescence replacement and custom FPGA-based bridging solutions. It’s compatible out-of-the-box with most VME controllers that support PMC mapping (including GE Fanuc Series 90-30/70, Motorola MVME, and some Bally/General Electric PACs). In many cases, it cuts integration time by 60–70% compared to developing a bespoke interface board—and since it’s a mature, field-proven design (first released 2006, last hardware revision 2013), spares availability is predictable. You’ll also avoid NRE fees or toolchain licensing costs associated with programmable logic alternatives.

Installation & Maintenance

Mount it in a well-ventilated 6U VME crate—avoid stacking directly above high-power CPU cards unless forced-air cooling is present. Ensure your VME backplane complies with IEEE 1014-1987 (VME64) or later; earlier versions may lack proper PMC address decoding. Wiring is straightforward: just connect the CADDY to the backplane with standard VME edge fingers—no jumpers or DIP switches needed. For maintenance: inspect the gold-finger contacts annually for oxidation (especially in humid environments), verify PMC retention screws are snug (they loosen over thermal cycling), and check for firmware updates only if using it with newer PMC modules that require specific VME address mapping tweaks (rare, but documented in GE’s PMC-CADDY Application Note AN-211).

Quality & Certifications

The VME-PMC-CADDY carries CE marking (EMC Directive 2014/30/EU and Low Voltage Directive 2014/35/EU), UL 61010-1 certification (for lab equipment safety), and RoHS 2011/65/EU compliance. It’s manufactured under ISO 9001:2015 processes at GE’s former Dunfermline facility (now part of Emerson’s industrial automation supply chain). Warranty is 365 days—covers material defects and functional failure under normal use. No extended warranty options exist, but field-replaceable units ship with full traceability (lot number, date code, burn-in report).

Our Order Placement Process & Guarantees:

• Warranty: 365 days from delivery date.

• Delivery: 1 week for in-stock units; up to 4 weeks for special configurations (though we rarely need that long—most orders ship same-day).

• Payment: 50% advance, balance before dispatch.

• Shipping: FedEx, UPS, or DHL Express—fully tracked, with insurance included.

Reviews

There are no reviews yet.