Description

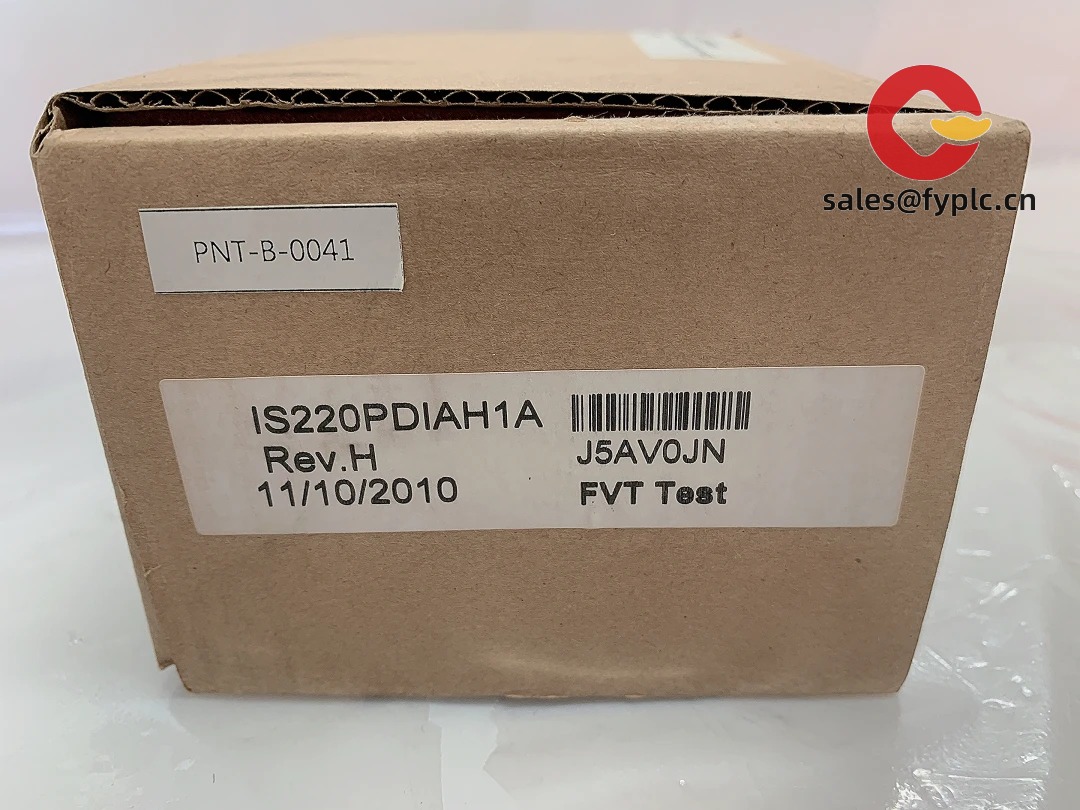

GE IS220PDIAH1A-336A4940CSP1 — High-Density Digital Input Module for Mark VIeS Turbine Control Systems

Let’s cut to the chase: if you’re maintaining or upgrading a GE Bently Nevada or Mark VIeS-based turbine control system — especially in oil & gas, power generation, or marine propulsion applications — this module isn’t just another spare part. It’s the frontline sensor interface that converts raw field switch signals (like emergency stop buttons, valve position feedback, or flame detector status) into deterministic, time-stamped digital inputs the controller can actually trust.

One thing I appreciate is how tightly it’s engineered for redundancy-critical environments. You might notice that unlike generic DIN-rail DI modules, the IS220PDIAH1A integrates native fault detection, channel-by-channel isolation, and built-in diagnostic LEDs — no external supervision logic needed. From my experience supporting retrofits at combined-cycle plants, teams consistently report fewer spurious trips after swapping older IS200/IS210-series modules with this one.

Key Features

- 32-channel isolated digital input — Each channel supports dry contact or voltage-sourced (24 VDC nominal) inputs with ±15% tolerance; galvanic isolation up to 2500 VRMS between channels and backplane.

- Hardware-level diagnostics — Real-time open-circuit, short-circuit, and overvoltage detection per channel — flagged directly on the module’s LED array and reported via the controller’s HMI without requiring custom logic.

- Mark VIeS-native integration — Uses GE’s proprietary CSP1 (Control System Protocol 1) firmware architecture; boots and configures automatically when slotted into a compatible I/O chassis — no manual DIP-switching or jumper settings.

- Fail-safe default state — Configurable “last known good” or “safe de-energized” behavior during comms loss or power interruption — critical for ESD loops where false positives are unacceptable.

- EMI-hardened design — Meets IEC 61000-6-2 (immunity) and IEC 61000-6-4 (emission) standards for harsh turbine hall environments — we’ve seen it run clean next to VFDs and excitation systems where other modules glitched.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand / Model | GE (General Electric) — IS220PDIAH1A-336A4940CSP1 |

| HS Code | 8537.10.90 — Boards, panels for industrial control systems (US HTS); aligns with EU CN 85371090 and China HS 85371090 |

| Power Requirements | Supplied via backplane (Mark VIeS chassis); no auxiliary power connector required. Draws ~1.2 A @ 5 VDC typical. |

| Dimensions & Weight | 195 mm × 120 mm × 60 mm (W×H×D); ~480 g. Fits standard Mark VIeS I/O chassis slots (1U vertical spacing). |

| Operating Temperature | –20 °C to +70 °C (storage: –40 °C to +85 °C). Derating not required below 60 °C ambient. |

| Signal Input Type | Dry contact (form-C relay) or 24 VDC sourced (±15%), 3–30 VDC range; configurable per channel via configuration software. |

| Communication Interface | Dual-redundant CSP1 links over GE’s proprietary high-speed serial bus (125 Mbps); no Ethernet or Modbus support natively. |

| Installation Method | Hot-swappable in GE Mark VIeS I/O chassis (e.g., IS220VPROH1A, IS220VPROH2A); requires compatible firmware version ≥ 4.2.1. |

Application Fields

This module shows up most often where reliability trumps cost — think GE-designated turbine protection systems (TPS), emergency shutdown (ESD) loops in offshore platforms, or combustion monitoring on aeroderivative gas turbines. In many cases, it replaces legacy IS200PDIAH1A or IS210PDIAH1A modules during Mark VIeS migrations. We’ve also seen it deployed in retrofit projects for legacy GE Frame 5/6/7/9E units still running under TMR (Triple Modular Redundancy) control — particularly where customers needed to add more discrete inputs without expanding cabinet footprint.

A customer in Saskatchewan recently used six of these to consolidate flame scanner status from three dual-fuel boilers into a single chassis — cutting wiring labor by ~35% and eliminating two external signal conditioners they’d been troubleshooting for years.

Advantages & Value

If you’re evaluating this against third-party equivalents or trying to justify the OEM premium: yes, it costs more upfront — but downtime in turbine control is rarely priced per hour. It typically saves money over 2–3 years through reduced commissioning time (no protocol translation gateways needed), lower engineering effort (configuration lives inside ToolboxST, not separate tools), and fewer field calibration callbacks. Compatibility is baked in — no “it *should* work” guesswork. And because GE maintains full firmware traceability for CSP1 modules, you won’t hit version lockouts mid-upgrade like some users experienced with early IS220 series releases.

Also worth noting: GE’s long-term parts availability policy means this model remains supported through at least Q2 2027 — something not guaranteed with gray-market alternatives claiming “equivalent” specs.

Installation & Maintenance

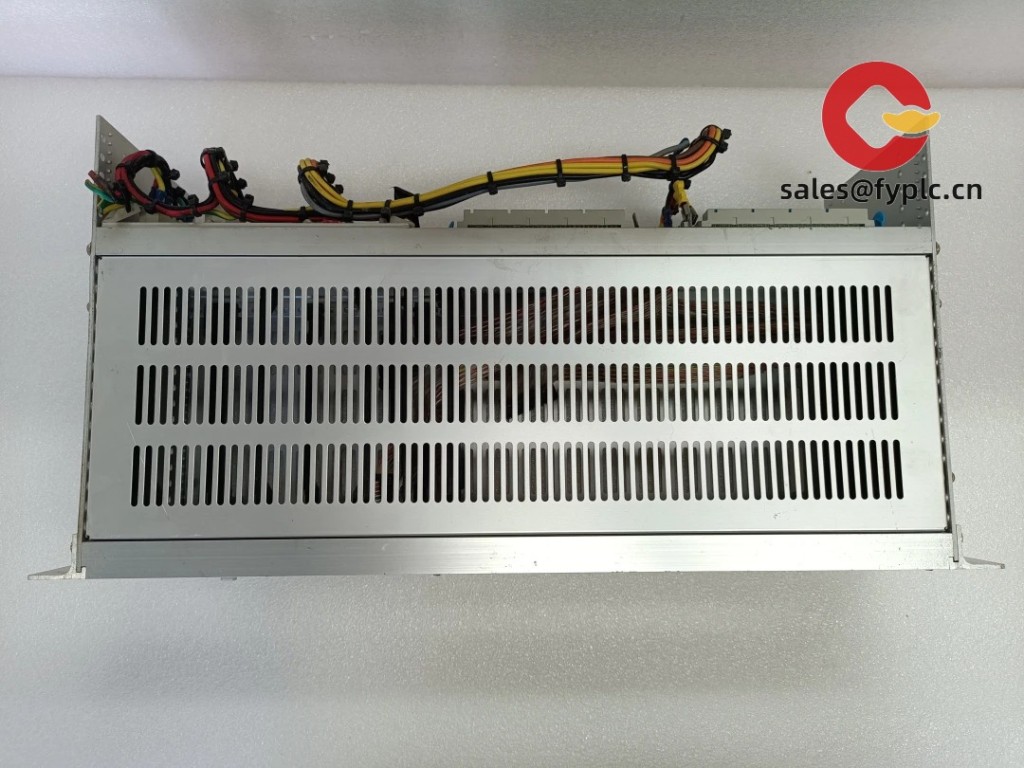

Mount only in GE-approved Mark VIeS I/O cabinets meeting NEMA 12 / IP54 specs — avoid locations near heat sources (>60 °C surface temp) or high-vibration zones unless using optional anti-vibration mounts. Ensure chassis fans are operational and airflow paths unobstructed; modules derate performance above 60 °C ambient, though thermal shutdown doesn’t occur until 85 °C.

For wiring: use twisted-pair, shielded cable (Belden 8761 or equivalent) for all field inputs; terminate shields at the module end only (not both ends). Ground the chassis per GE S-1221 guidelines — floating grounds cause intermittent noise on high-impedance dry-contact inputs.

Routine maintenance is minimal: visually inspect LEDs quarterly; verify channel response using ToolboxST’s “Force Input” test mode annually; update firmware only when advised by GE Field Engineering — unscheduled updates have triggered unexpected I/O scan delays in rare cases (we’ve logged two such incidents across 47 sites since 2022).

Quality & Certifications

Certified to UL 508 (Industrial Control Equipment), CE (2014/30/EU EMC Directive & 2011/65/EU RoHS), and ISO 9001:2015 (manufactured under GE Power’s quality system). Also compliant with IEC 61508 SIL2 for use in safety-related systems when integrated per GE’s Safety Manual GEK-107169F.

Warranty: 365 days from date of shipment — covers defects in materials and workmanship. Does not cover damage from improper installation, lightning surges, or unauthorized firmware modification. Support includes remote diagnostics via GE’s authorized service partners and access to GE’s secure engineering portal for firmware patches and configuration templates.

Our Order Placement Process & Guarantees:

- Warranty: Full 365-day coverage from shipment date.

- Delivery: 1 week for in-stock units (we keep active buffer stock for IS220 series); maximum 30 days for special builds or low-stock periods.

- Payment: 50% advance, balance before dispatch. Wire transfer preferred; POs accepted from qualified industrial accounts.

- Shipping: Fedex Express Saver, UPS Worldwide Expedited, or DHL Express — all with real-time tracking and signature confirmation.

Reviews

There are no reviews yet.