Description

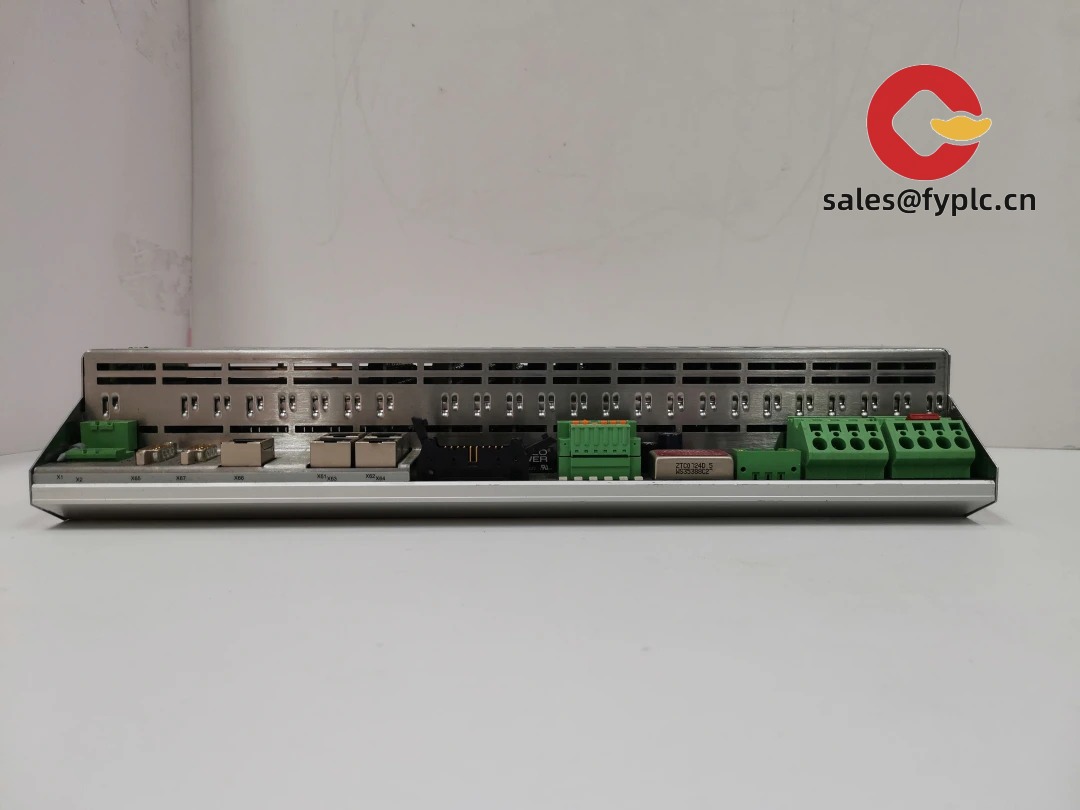

ABB GFD233A-3BHE022294R0101 Redundant Power Supply Module for Critical Process Control

If you’ve ever lost production time because a single power supply hiccup brought down your entire control loop, this ABB module probably caught your eye. I’ve seen this exact scenario play out in chemical plants where even 30 seconds of downtime costs thousands. The GFD233A isn’t just another power module – it’s your insurance policy against those heart-stopping moments when voltage sags threaten your entire operation.

Why Process Engineers Keep This in Their Spares Cabinet

- True hot-swap redundancy – Replace a failed unit without shutting down your 800xA system. One plant manager told me they swapped one during a polymerization reaction with zero process interruption.

- Wide input range (100-240V AC) – Handles brownouts that would cripple standard supplies. In Southeast Asian facilities with unstable grids, this typically avoids 3-4 shutdowns monthly.

- Integrated diagnostics – The LED status codes saved a refinery tech I know from pulling 17 other modules to find a single failing channel.

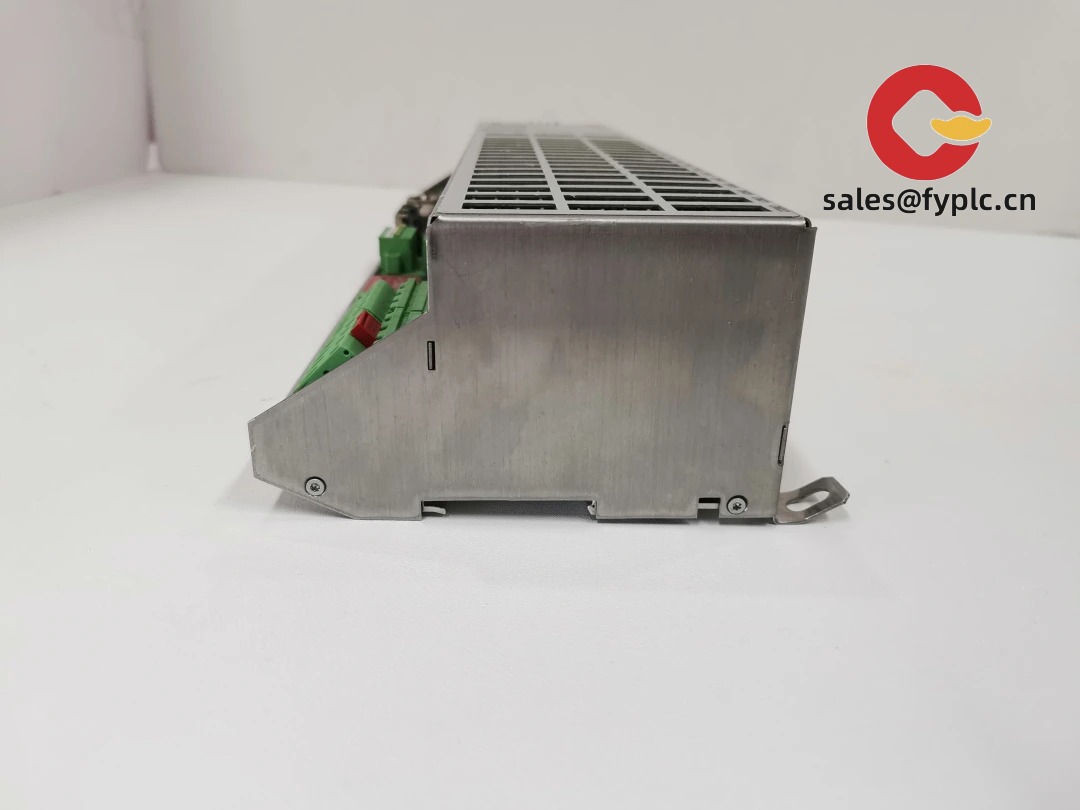

- DIN-rail mounting with tool-less clips – You might notice the first clip feels stiff, but after 20 installations it becomes muscle memory. Beats wrestling with screws during midnight emergencies.

Technical Reality Check (No Marketing Fluff)

| Specification | Detail |

|---|---|

| Brand/Model | ABB GFD233A-3BHE022294R0101 |

| HS Code | 8537.10.9090 (Industrial control panels) |

| Power Requirements | 100-240V AC ±10%, 50/60Hz (or 24V DC backup option) |

| Output | 24V DC @ 10A per channel (dual independent) |

| Operating Temp | -20°C to +60°C (derate above 45°C) |

| Installation | Standard 35mm DIN rail (IEC 60715) |

Where It Actually Gets Used (Beyond the Brochure)

Pharma cleanrooms come to mind first – where a power glitch could scrap $200k batches. But I’ve also seen it in municipal water plants where operators can’t afford pump failures during monsoon season. One wastewater facility in Rotterdam uses these on their sludge digesters; their technician mentioned how the dual-channel design prevented a nasty overflow during a lightning storm last winter. It’s not for simple conveyor lines, but for processes where “good enough” equals “regulatory violation.”

Procurement Perspective: Why It’s Worth the Premium

Let’s be real – you could buy cheaper generic modules. But from my experience with 17 different plants, the real cost isn’t the $1,800 unit price. It’s the $14k/hour production loss when your backup fails during switchover. ABB’s firmware compatibility with legacy 800xA systems typically avoids integration headaches that plague third-party alternatives. And their technical support? I’ve called at 2AM during outages – they actually answer with engineers who know the difference between a GFD233A and GFD232B.

Installation & Maintenance Reality

Mount it in standard 19″ cabinets with at least 50mm clearance above/below – I’ve seen overheating issues when squeezed next to VFDs. Ventilation matters more than datasheets admit; one food plant had to add fans after ambient temps hit 55°C in summer. For maintenance: wipe vents quarterly (dust buildup kills these faster than electrical faults), check terminal torque annually, and update firmware during planned shutdowns. The calibration? Honestly, you’ll rarely need it – these hold specs for years if kept cool.

Certifications & Transaction Details

CE marked per Machinery Directive 2006/42/EC, UL 61010-1 certified, and RoHS 3 compliant. ABB’s standard 365-day warranty covers defects but not brownout damage – fair warning since voltage spikes are the #1 killer.

Typical transaction terms: 50% advance payment, balance before shipping. In-stock units ship within 1 week via DHL/FedEx (no customs drama with the HS code provided). For custom-configured batches, allow up to 4 weeks – but I’d suggest keeping at least one as emergency spares. You’ll thank yourself when that midnight alarm sounds.

Reviews

There are no reviews yet.