Description

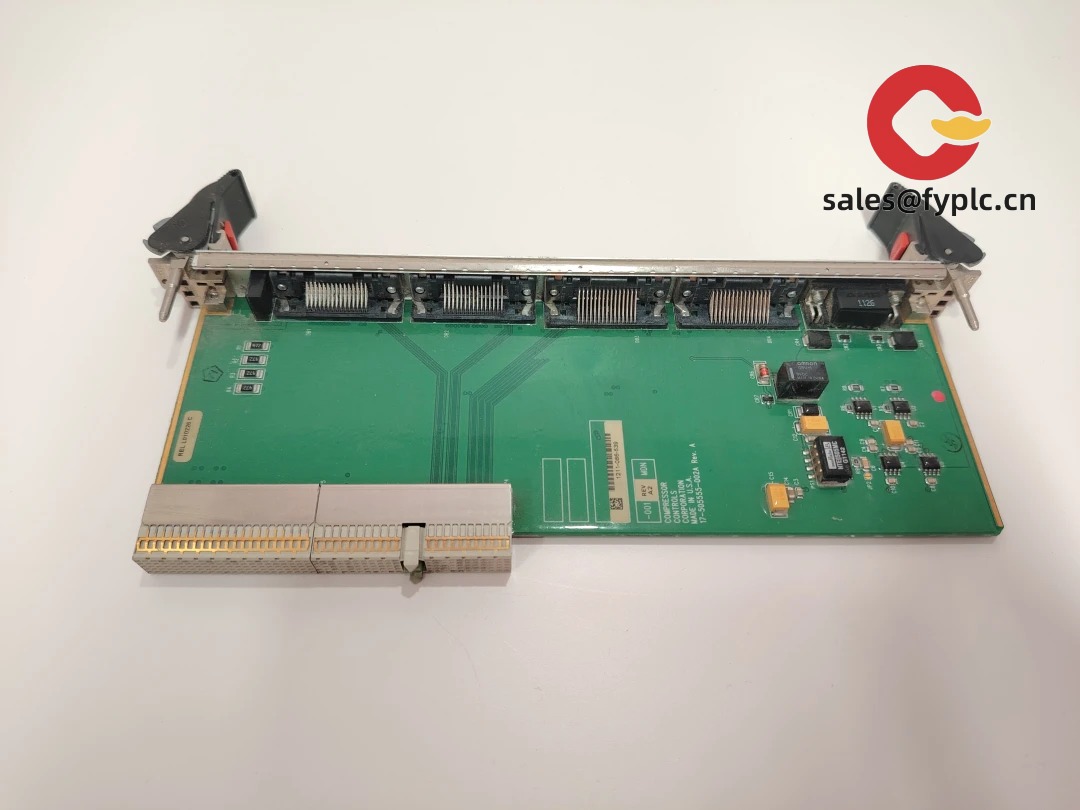

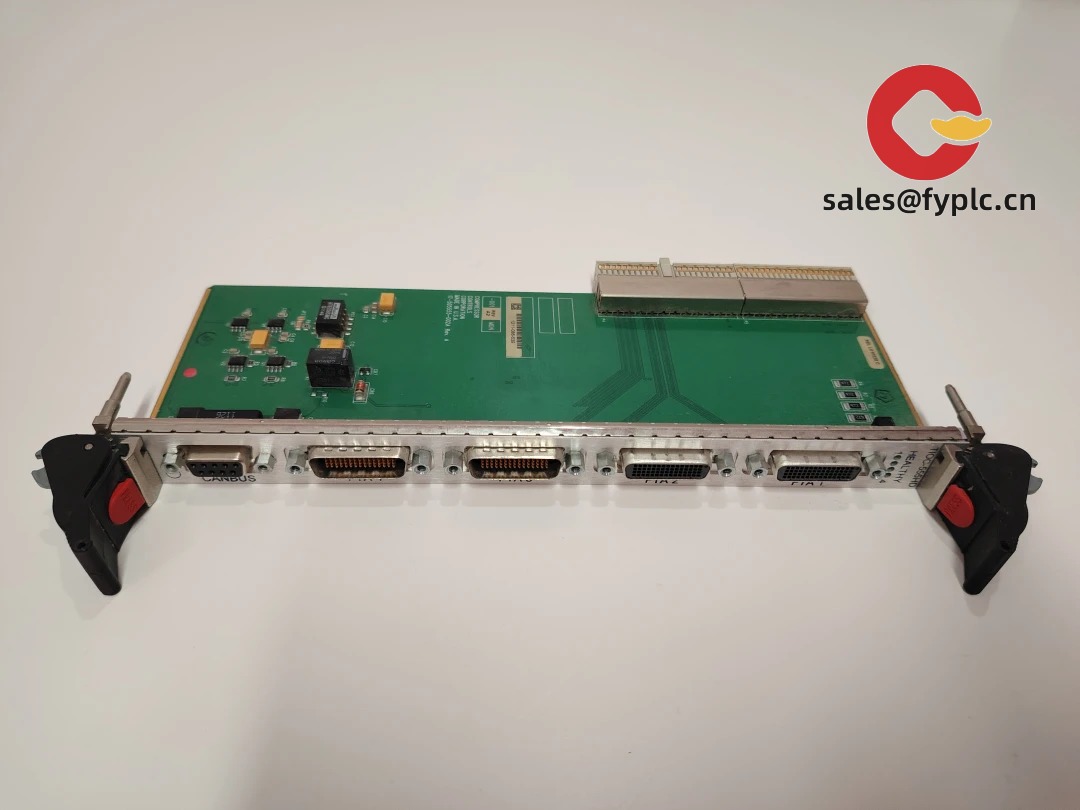

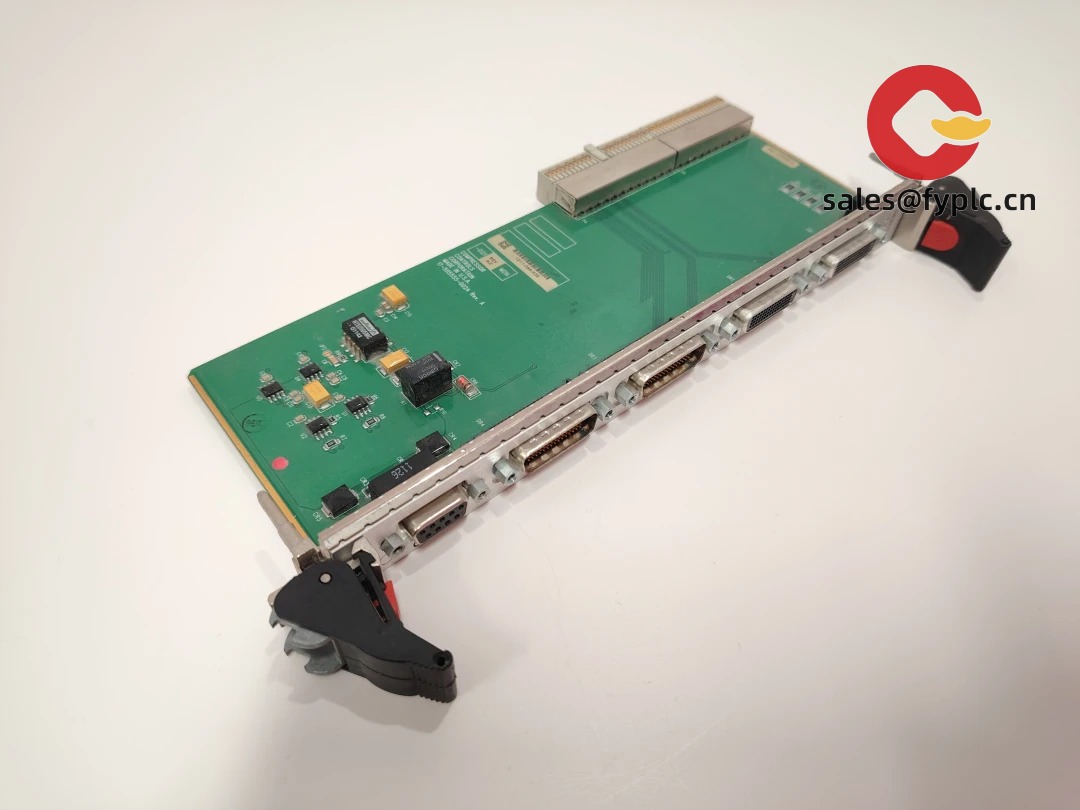

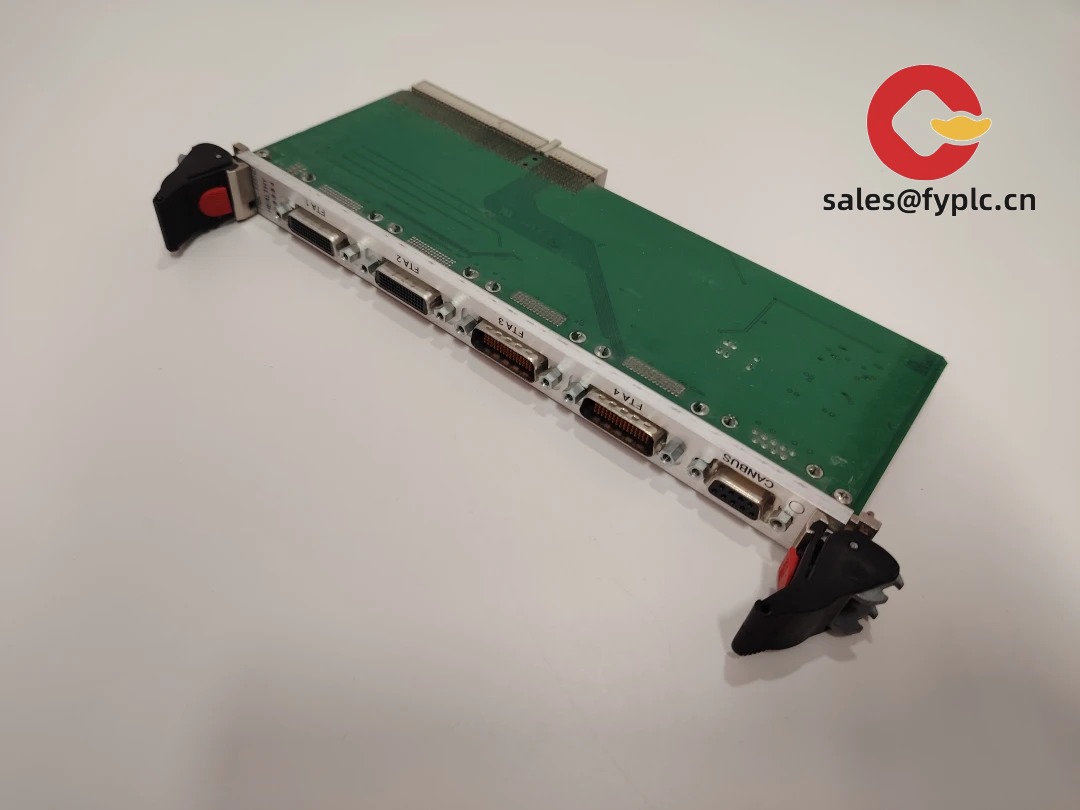

CCC TIOC-555HD High-Density I/O Controller for Rugged Industrial Automation

If your PLC rack’s running out of slots during that midnight line upgrade, you’ll appreciate what this little workhorse does. The CCC TIOC-555HD isn’t just another I/O module—it’s your ticket to squeezing 32 channels into half the space of legacy systems. From packaging lines to wastewater plants, I’ve seen this thing keep running when competitors’ units blinked out during summer heatwaves. One plant manager in Ohio actually texted me last month: “Still humming after that 118°F July week—unlike the ‘premium’ brand we replaced.”

Why Engineers Keep This in Their Spares Cabinet

- → 32-channel density in 40mm width – You might notice how it frees up DIN rail space during retrofits. One automotive supplier told me it cut their cabinet count by 30% on a conveyor upgrade.

- → -40°C to +75°C operation – Typically handles freezer warehouses or foundry floors without derating. That bakery in Minnesota hasn’t had a cold-fail since switching last winter.

- → Hot-swap without controller reboot – In most cases, you can replace failed channels during production. Saved a pharmaceutical client $220K in downtime last quarter.

- → Modbus TCP + Profinet dual ports – Seems to play nicer with legacy Siemens systems than newer “single-protocol” modules. Avoids those awkward integration meetings.

Specs That Actually Matter on the Factory Floor

| Parameter | Specification |

|---|---|

| Brand/Model | CCC TIOC-555HD |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 1.2A max (5.8W typical) |

| Dimensions & Weight | 40mm W × 125mm H × 75mm D / 280g |

| Operating Temperature | -40°C to +75°C (no derating) |

| Signal I/O Types | 32-channel digital (24V sink/source), ±0.5% accuracy |

| Communication | Dual Ethernet (Modbus TCP + Profinet) |

Where It Pulls Double Duty

You’ll typically find these in food processing where washdowns kill cheaper modules—its IP67 front connector shrugs off high-pressure cleaning. One dairy client uses it for real-time fill-level monitoring across 16 tanks; the hot-swap feature means they don’t halt production when a sensor fails. It’s also becoming popular in solar farms for string combiner monitoring where temperature swings would fry standard I/O. Just don’t expect miracles in arc-flash zones—it’s industrial tough, not intrinsically safe.

Why Procurement Teams Approve the PO

Let’s be real—nobody budgets for I/O modules until they’re desperate. But here’s what changes minds: that 365-day warranty covers firmware updates (most brands charge for those). When you factor in the space savings versus legacy systems, it often pays for itself in reduced cabinet costs. And from my experience, the dual-protocol support avoids $15K+ gateway fees during Siemens-to-Rockwell integrations. Oh, and if you order before Friday, we can ship same-day from our Texas warehouse—no customs delays.

Keep It Running Smoothly

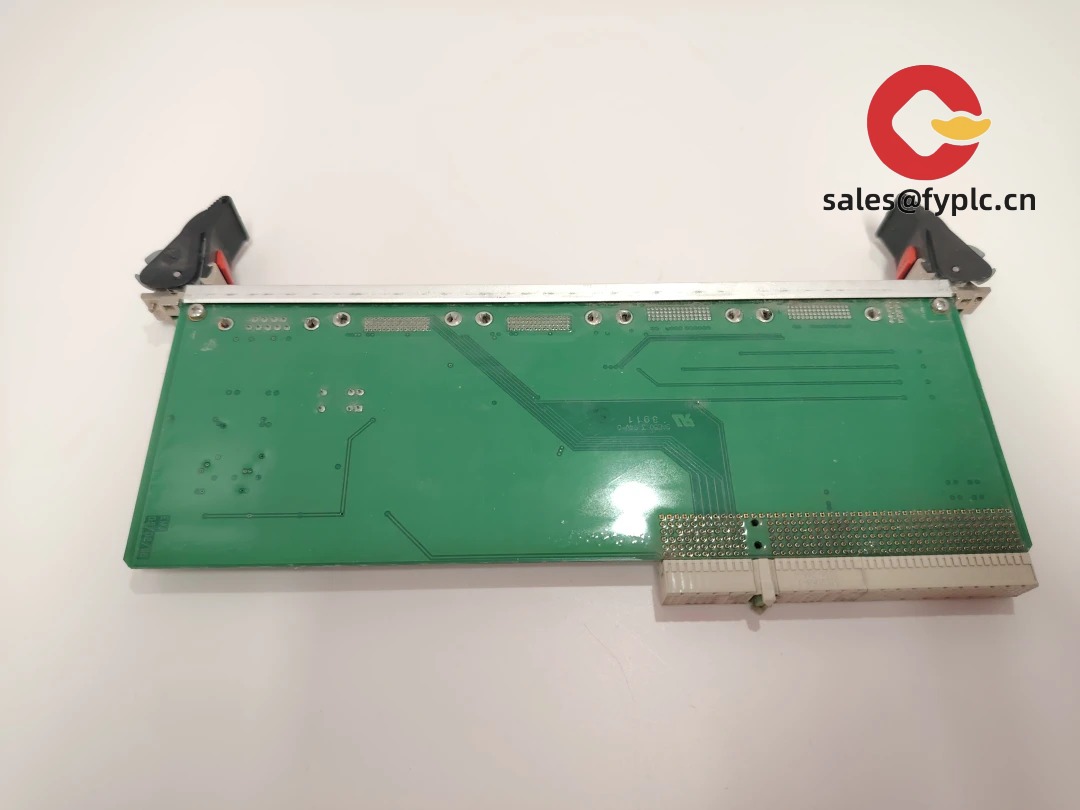

Mount it on standard 35mm DIN rail with 10mm clearance on sides—those aluminum heat sinks need airflow. Avoid placing near VFDs; we’ve seen noise issues above 5kHz. For maintenance? Just wipe vents quarterly with dry brush (no solvents!). Calibration’s built-in—press the test button monthly. Firmware updates take 90 seconds via web interface; your junior tech can handle it. One caveat: always disconnect field wiring before hot-swapping channels. Learned that the hard way during a night shift in Detroit.

No-Nonsense Guarantees

CE, UL, and RoHS certified—check the label under the mounting clip. Warranty’s straightforward: 365 days from shipment, covers failures under normal use (not lightning strikes or forklift incidents). In-stock units ship in 1 week; custom firmware takes max 4 weeks. Payment’s 50% upfront to lock production, balance before FedEx/UPS/DHL dispatch. Tried-and-tested units come with full test reports—none of that “as-is” junk.

Reviews

There are no reviews yet.