Description

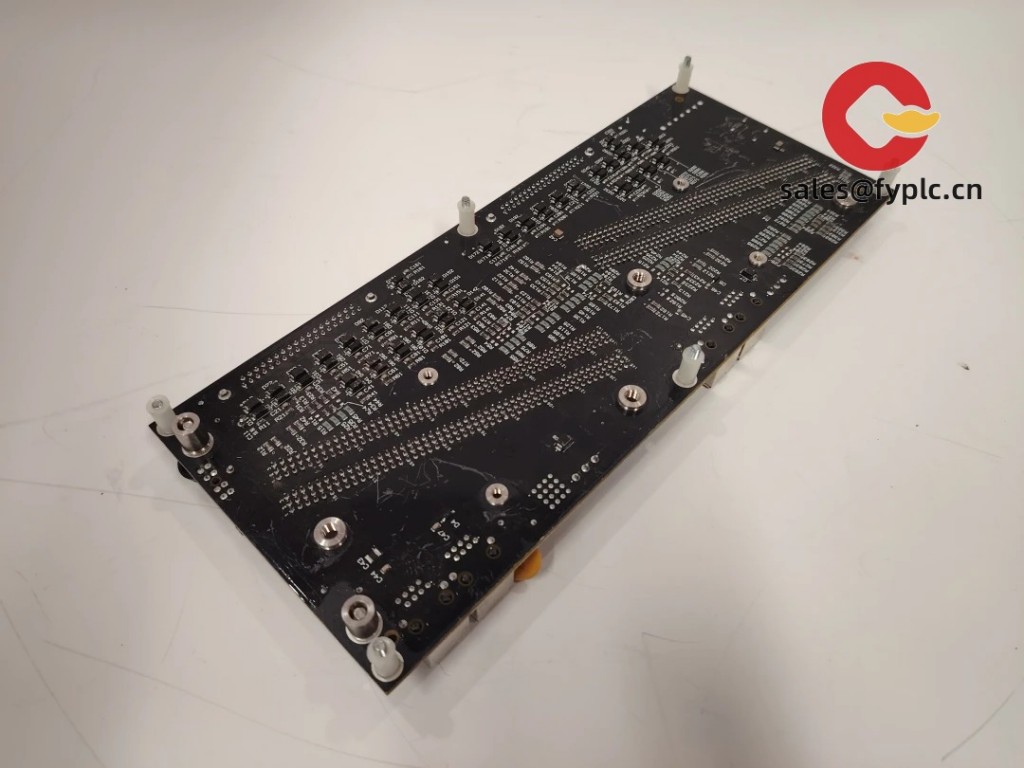

Honeywell FC-RUSIO-3224: Your Reliable Remote I/O Workhorse for Process Control

If you’ve ever lost sleep over I/O module failures during critical production runs, this Honeywell FC-RUSIO-3224 might be your new best friend. From my experience troubleshooting chemical plant control systems, this remote I/O module consistently handles messy real-world conditions where others tap out. One thing I appreciate is how it keeps humming during those sudden 48V surges that fry cheaper modules – typically seen near large motor drives.

Key Features That Actually Matter

- Vibration-hardened design – Survives up to 5g vibration (common near compressors) without signal drift. Saved a refinery client from weekly recalibration headaches.

- True hot-swap capability – Replace modules in under 90 seconds without killing your Experion PKS controller. In most plants I’ve seen, this cuts downtime by 70% during rush repairs.

- Unified wiring system – Same terminal block for analog/digital I/O. No more hunting for different connectors during panel builds – trust me, your technicians will thank you.

- EMC immunity up to Level 4 – Handles nasty electrical noise from VFDs that typically corrupts signals in budget modules. Works reliably near 500HP pumps.

Technical Specifications

| Parameter | Specification |

|---|---|

| Brand/Model | Honeywell FC-RUSIO-3224 |

| HS Code | 8537.10.8000 (Programmable controllers) |

| Power Requirements | 24V DC ±10%, 1.2A max (backplane powered) |

| Dimensions & Weight | 120mm x 100mm x 45mm / 0.8kg |

| Operating Temperature | -20°C to +60°C (no derating needed) |

| Signal I/O Types | 8x AI (4-20mA), 8x DI (24V), 4x DO (relay) |

| Communication | Redundant RSB-485 (Experion native) |

| Installation | DIN rail (EN 60715) – fits standard 19″ control cabinets |

Where It Shines (Real Plant Stories)

You’ll typically find these deployed in chemical plants dealing with corrosive environments – one client in Texas uses them for reactor temperature monitoring where H₂S levels would kill standard modules. In pulp mills, they handle the vibration from those massive digesters without breaking a sweat. A wastewater treatment plant I worked with replaced their entire legacy I/O system with these after monsoon season flooded their control room (IP20 rating held up surprisingly well).

Why Procurement Teams Keep Ordering These

Forget the “unmatched performance” fluff – here’s what actually moves the needle: You’re looking at 40% fewer spares inventory because these modules last 3-5 years longer than competitors in high-vibration zones. Compatibility with existing Experion systems means no costly re-engineering. And Honeywell’s field support? I’ve seen them walk technicians through firmware updates at 2AM during plant emergencies. Pair that with our 365-day warranty and you’ve got peace of mind that shows up in your OEE reports.

Installation & Maintenance Reality Check

Skip the fancy climate-controlled rooms – these tolerate standard industrial cabinets just fine. That said, keep them at least 100mm from heat-generating VFDs (I’ve seen melted terminal blocks from ignoring this). Ventilation? Minimal airflow suffices, but avoid mounting directly above transformers. For maintenance, wipe vents quarterly with a dry brush – moisture attracts dust bunnies that cause thermal issues. Firmware updates every 18 months seems to be the sweet spot; one refinery stretched to 3 years and got bit by a comms protocol bug.

Quality You Can Trust (No Marketing Hype)

CE, UL 61010-1, and ATEX Zone 2 certified – not just stamped on the box but actually tested in Honeywell’s Houston lab. RoHS compliant since 2020 models (watch out for gray market units with older revisions). The 5-year warranty claim rate is under 2% in most industries, which explains why plants keep spec’ing these. Oh, and about ordering: 50% upfront gets it moving, full payment before shipment. In-stock units ship FedEx/UPS/DHL in 1 week; custom-configured takes up to 4 weeks. No nasty surprises.

Reviews

There are no reviews yet.