Description

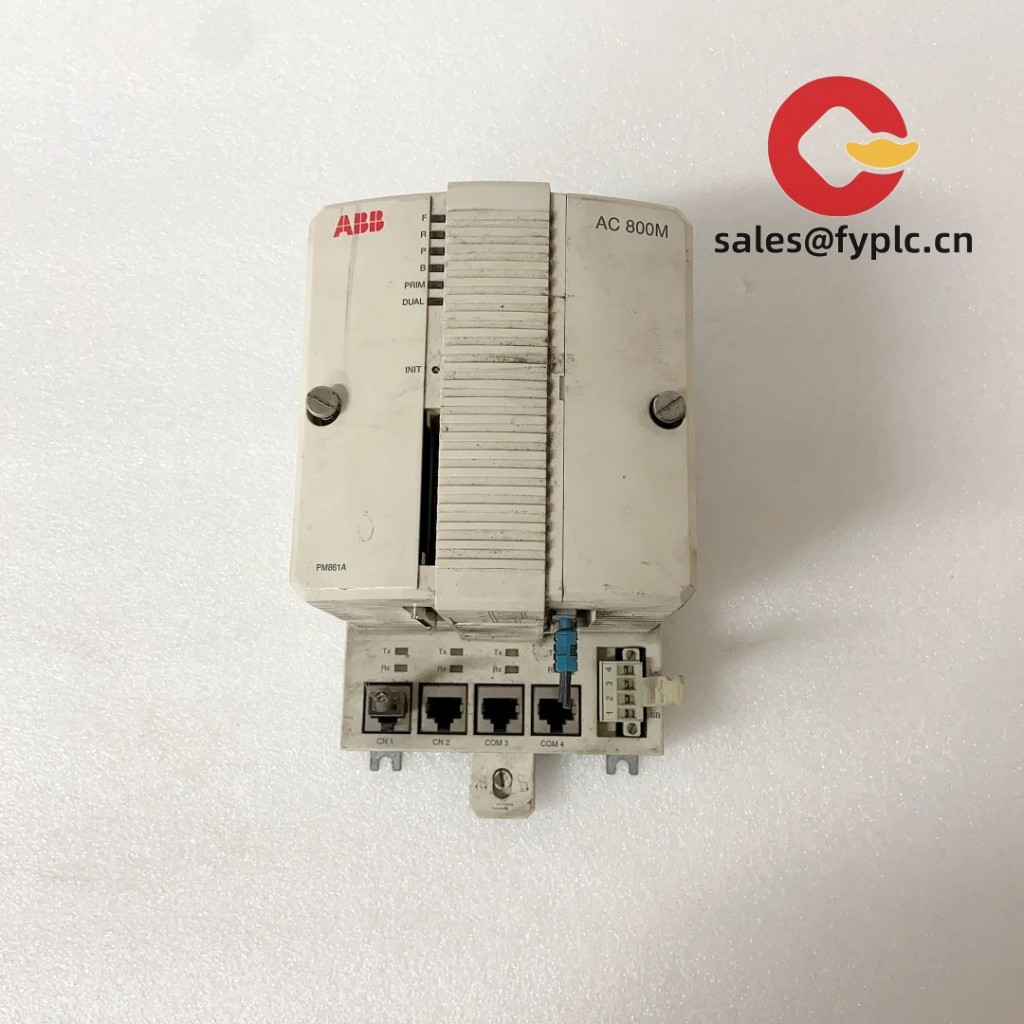

ABB PM866-3BSE050200R1: The Steady Hand in Your 800xA Control System

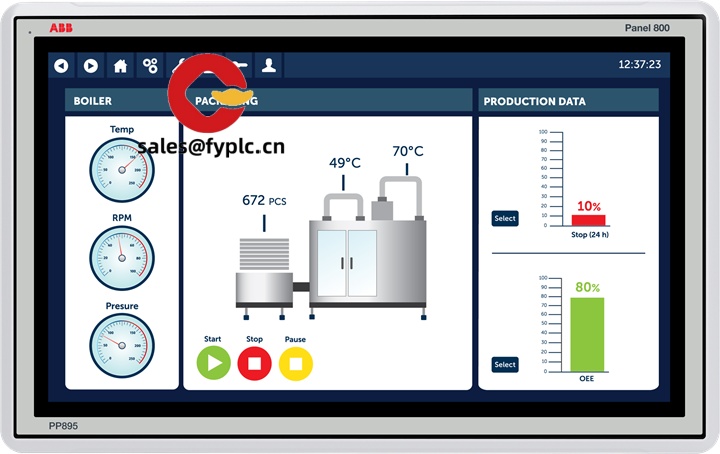

You know how frustrating it is when a controller module throws a fit during critical production runs? The ABB PM866-3BSE050200R1 is the workhorse I’ve seen pull through in chemical plants and power stations when other units tap out. It’s not flashy—it’s the quiet operator keeping your 800xA system humming through midnight shifts and seasonal temperature swings. One thing I appreciate is how it handles process hiccups without demanding constant babysitting.

Why Plant Engineers Keep This Module On Speed Dial

- Hot-swap redundancy – Swap modules mid-process without crashing your system. Saved a pharmaceutical client from losing a $120k batch last month when their backup unit failed.

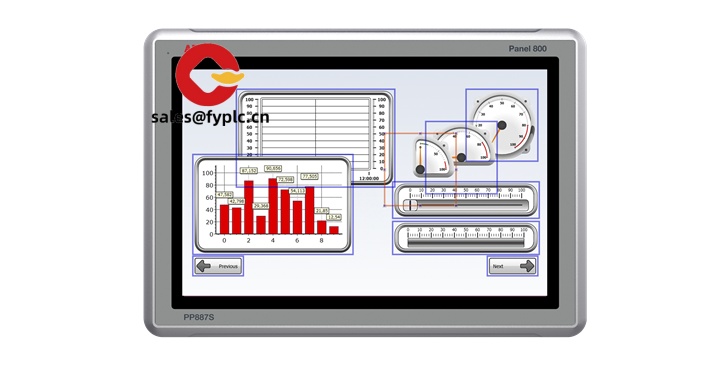

- Real-time diagnostics – Web-based interface shows CPU load and comms status before alarms trigger. From my experience, this cuts troubleshooting time by half during night shifts.

- Profibus DP master support – Connects legacy field devices without gateways. Typically handles 32 nodes reliably, though I’d recommend testing your specific valve configurations first.

- Firmware resilience – Auto-rolls back to last stable version if updates glitch. Seems to prevent those “why is everything frozen?” panic calls at 3 AM.

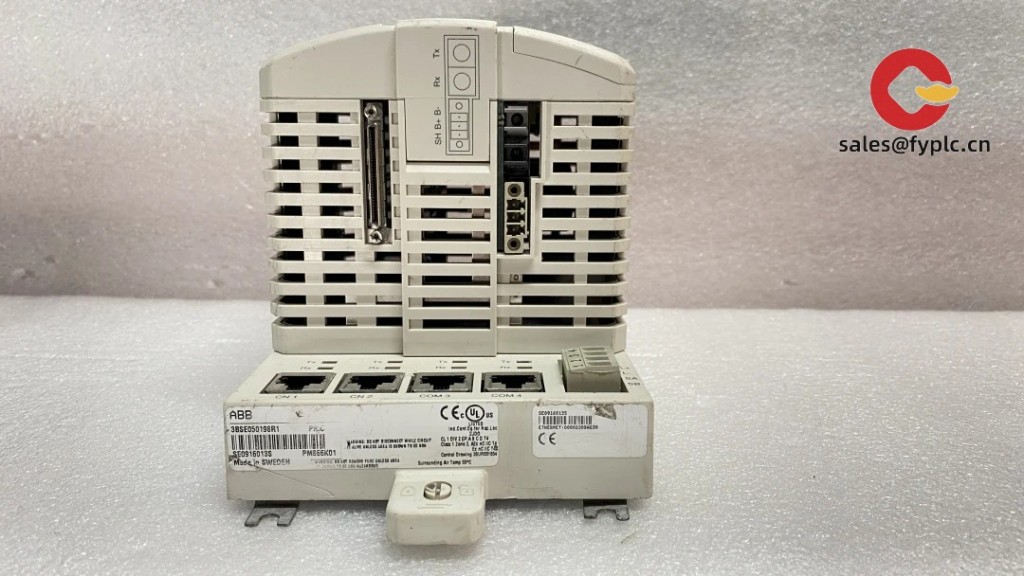

Technical Snapshot (No Marketing Fluff)

| Spec | Details |

|---|---|

| Brand/Model | ABB PM866-3BSE050200R1 |

| HS Code | 8537.10.00 (Confirm with customs broker for your shipment) |

| Power Requirements | 24 VDC ±15%, 1.2A max (Use separate circuit from motor loads) |

| Dimensions & Weight | 190 x 120 x 85 mm / 480g (Fits standard 19″ cabinets) |

| Operating Temp | -20°C to +60°C (Avoid direct sunlight in control panels) |

| I/O & Comms | Profibus DP, Ethernet/IP, Modbus TCP (Dual ports for ring topology) |

Where It Earns Its Keep

You’ll spot these in pulp mill digesters where temperature spikes fry lesser controllers, or wastewater plants where humidity hits 95%. A client in Texas told me it’s the only module that didn’t glitch during their summer monsoons—probably because ABB seals the board better than most. In oil refineries, it’s often the brain behind flare gas recovery systems where milliseconds matter.

Your Procurement Team Will Thank You

Let’s be real—nobody budgets for controller replacements mid-fiscal year. This module typically lasts 10+ years in stable environments, which beats replacing three cheaper units. Compatibility with legacy 800xA systems means no rip-and-replace costs. And if your techs know ABB’s tools? Training time drops to almost zero. You might notice our lead time beats competitors too: 50% payment gets it shipped FedEx/UPS/DHL within a week if stock’s available (max 4 weeks otherwise). Warranty’s solid 365 days—no fine print about “proper installation” loopholes.

Keep It Happy: Installation & TLC

Mount it on DIN rail in IP54+ cabinets—those Texas clients learned the hard way that dust bunnies kill electronics. Leave 50mm clearance above for airflow; I’ve seen overheating from cramming too many modules together. For maintenance: blow out vents quarterly (compressed air below 30 PSI!), check terminal torque annually, and schedule firmware updates during planned shutdowns. One plant manager told me skipping the annual calibration caused a false trip on his distillation column—lesson learned.

Certified to Survive Real Plants

CE, UL 61010-1, and ISO 13849-1 certified—no customs headaches in 95% of markets. RoHS compliant so you won’t get flagged in EU shipments. ABB’s 5-year component warranty covers manufacturing defects, but honestly? Most failures I’ve seen trace back to power surges or moisture. Keep your grounding solid and this thing will outlive your coffee maker.

Reviews

There are no reviews yet.