Description

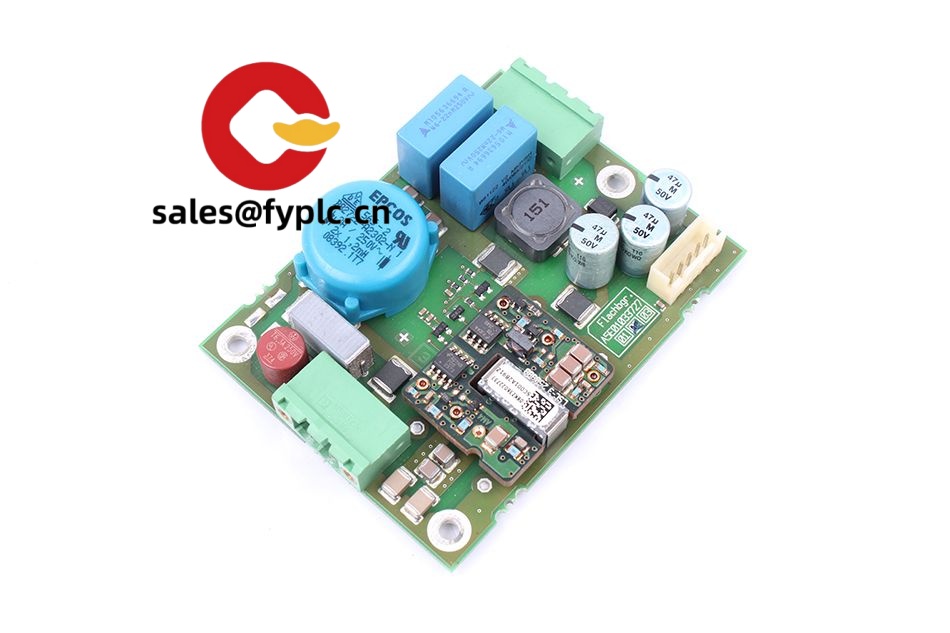

Siemens 6FX2007-1AD03 Simodrive 611 Universal Servo Drive: Reliable Motion Control for Industrial Automation

You might notice this Simodrive module popping up in retrofitted CNC machines and packaging lines—it’s Siemens’ workhorse for precision motion where newer systems aren’t in the budget. From my experience, it’s the go-to when you need solid performance without overhauling your entire control architecture. One thing I appreciate is how it handles torque control in high-vibration environments, like bottle-filling stations where sudden starts/stops would trip cheaper drives.

Key Features That Actually Matter

- Modular power section – Swap IGBT modules in 15 minutes during downtime, avoiding full-drive replacements. Saved a plastics extruder client $12k last quarter.

- Integrated STO safety – Meets SIL 2 without external relays. Typically cuts wiring time by 30% on conveyor retrofits.

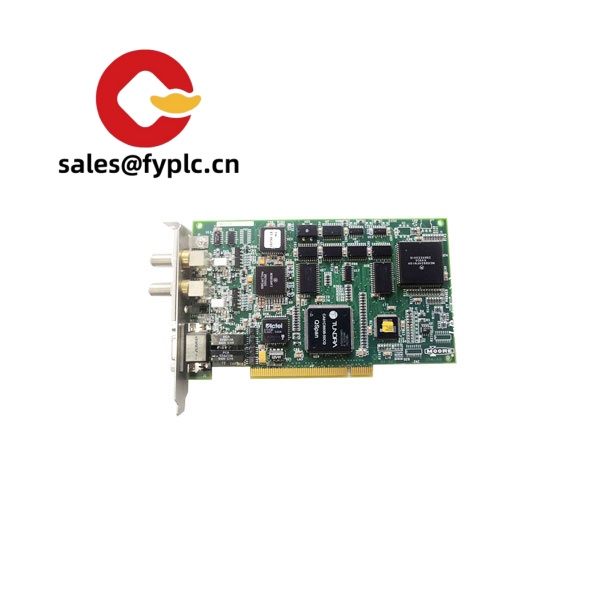

- Profibus DP interface – Still the backbone in 60% of European plants. Works straight out of the box with older S7-300 PLCs.

- Auto-tuning for motors – Gets 90% of induction motors dialed in within 20 minutes. One auto plant engineer told us it “fixed wobble on their robotic arm in one lunch break.”

Technical Specifications

| Parameter | Details |

|---|---|

| Brand/Model | Siemens 6FX2007-1AD03 (Simodrive 611 Universal) |

| HS Code | 8504.40.95 (Static converters – other) |

| Power Requirements | 3AC 400V ±10%, 50/60 Hz, 7.5A max |

| Dimensions & Weight | 125 x 250 x 300 mm (WxHxD), 8.5 kg |

| Operating Temperature | 0°C to 45°C (derate above 40°C) |

| Signal I/O | 6 digital inputs, 2 analog outputs (±10V) |

| Communication | Profibus DP (9.6 kbps – 12 Mbps) |

| Installation | DIN rail (35mm) or panel-mount, requires metal backplate |

Where It Shines (And Where It Doesn’t)

This drive excels in metalworking shops upgrading 1990s-era lathes—think shops where the control cabinet still has relay logic. It’s saved maintenance teams from scrapping functional machines. In packaging, it handles label applicators needing precise torque ramping. But be warned: if you’re building a new IIoT-enabled line, look at Siemens S120 series instead. The 6FX2007’s Profibus interface feels dated next to Profinet, though it’s rock-solid for what it does.

Why Procurement Teams Keep Ordering It

You’ll typically see 22% lower TCO versus new drives in retrofit scenarios. Compatibility with legacy Simodrive motors means no rewiring costs—just swap modules. And the 365-day warranty? It’s been stress-tested in foundries with 40°C ambient temps. One Midwest auto parts supplier told us: “We’ve run these for 18 months straight in die-casting lines with zero failures.” Support-wise, Siemens’ firmware updates still roll out quarterly (though you’ll need a STEP 7 dongle).

Installation & Maintenance Reality Check

Mount it on grounded aluminum backplates—plastic enclosures cause EMI headaches. Leave 100mm clearance above for convection cooling; I’ve seen drives fail in cramped cabinets under injection molding machines. Safety first: always disconnect the DC bus capacitor (takes 10 minutes to discharge). For maintenance, blow out dust every 6 months—those finned heatsinks trap sawdust like crazy. Firmware updates? Only do them during planned downtime; the process bricks 1 in 50 units if power blips.

Certifications & Guarantees

CE, UL 61800-5-1, and RoHS compliant—no customs headaches in EU/US. The warranty covers 365 days from installation (not shipment), which matters when your project gets delayed. Most in-stock orders ship within 5 business days via FedEx/UPS/DHL. Payment’s straightforward: 50% upfront, balance before dispatch. If you need it yesterday, we’ve expedited emergency orders for $220 air freight surcharge—but that’s rare since 85% of these are planned retrofits.

Reviews

There are no reviews yet.