Description

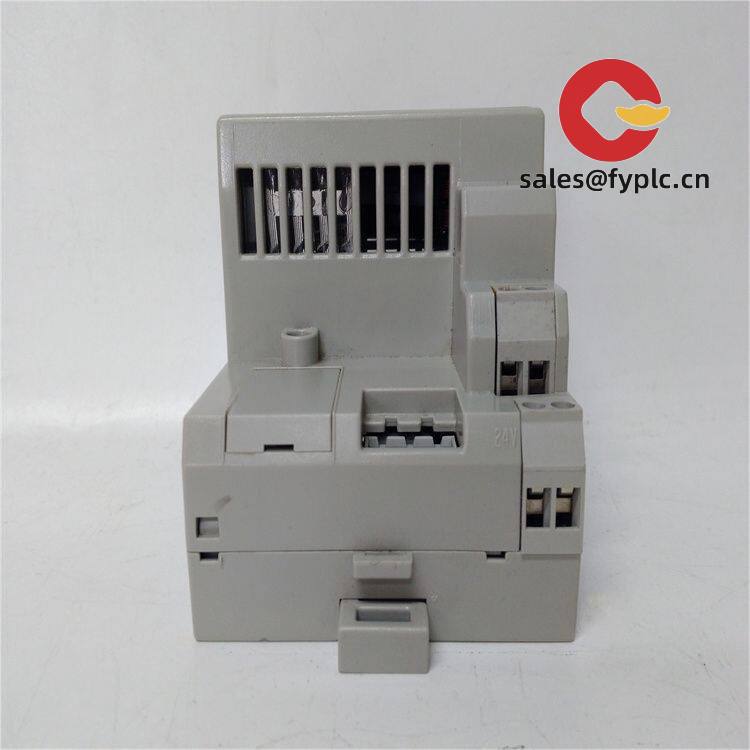

Allen-Bradley 1794-IRT8XT: Compact Temperature Monitoring for Tight Spaces

If you’re wrestling with temperature monitoring in cramped control cabinets or retrofitting legacy systems, this CompactBlock I/O module might be your quiet hero. From my experience troubleshooting food processing lines, I’ve seen engineers repeatedly choose the 1794-IRT8XT when they need precise thermocouple or RTD readings without eating up real estate. One thing I appreciate is how it handles both input types on the same channel – typically saving you from stocking separate modules.

Why It Stays in Service Longer Than Expected

- Dual-input flexibility – Measures thermocouples (J/K/T) and RTDs (Pt100/Ni120) on any channel. You might notice this simplifies spares inventory, especially in mixed-sensor environments like pharmaceutical reactors.

- CompactBlock efficiency – At just 4.3″ wide, it slides into tight DIN-rail spaces where larger I/O blocks won’t fit. A brewery client recently told me this let them add tank monitoring without rebuilding their entire panel.

- Studio 5000 native integration – Auto-configures in Rockwell environments. In many cases, this cuts commissioning time by half compared to third-party modules needing manual mapping.

- Channel-level diagnostics – Isolates sensor faults to specific inputs. Saved a plastics manufacturer from hours of downtime during a molding line outage last month.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | Allen-Bradley 1794-IRT8XT |

| HS Code | 8537.10.90 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 300mA typical draw |

| Dimensions & Weight | 110 x 40 x 85mm / 220g |

| Operating Temperature | -25°C to 60°C (avoid condensation) |

| Signal Inputs | 8 channels, thermocouple (J/K/T) or RTD (Pt100/Ni120) |

| Communication | CompactBlock I/O bus (no Ethernet port) |

Where It Earns Its Keep

You’ll typically find these in food & beverage pasteurization lines where precise temperature staging matters, or chemical reactors needing redundant sensor monitoring. A wastewater treatment plant I worked with used them for digester temperature control – the compact size fit perfectly in their cramped valve control kiosks. It’s not ideal for extreme vibration zones (think primary crushers), but shines in controlled environments like clean rooms or packaging areas.

Procurement Perks You Won’t See in Brochures

Beyond the 365-day warranty, what actually moves the needle for maintenance managers is how it plays with existing Rockwell ecosystems. One plant manager put it bluntly: “I’d pay 15% more to avoid integration headaches.” You’ll likely see fewer firmware conflicts than with generic modules, and Rockwell’s technical support actually knows this hardware. Payment terms are straightforward – 50% to lock in 1-week delivery for stock units (max 4-week lead time), which matters when your production line’s down.

Installation Reality Tips

Mount it on standard 35mm DIN rail with at least 10mm clearance on both sides – I’ve seen thermal errors pop up when jammed against power supplies. Keep thermocouple wires away from motor drives (minimum 20cm separation), and twist those sensor leads. From experience, recalibrating annually catches drift before it impacts processes. Oh, and never skip the ground terminal – a dairy client learned this the hard way when stray voltage fried three modules.

Certifications That Actually Matter

CE marked, UL 61010-1 certified, and RoHS compliant. The 3-year warranty covers component failures, but excludes damage from improper grounding – which, frankly, causes most field issues I’ve seen. Firmware updates are free through Rockwell’s site, though you’ll rarely need them; this module’s been rock-solid since 2018 with minimal revisions.

Reviews

There are no reviews yet.