Description

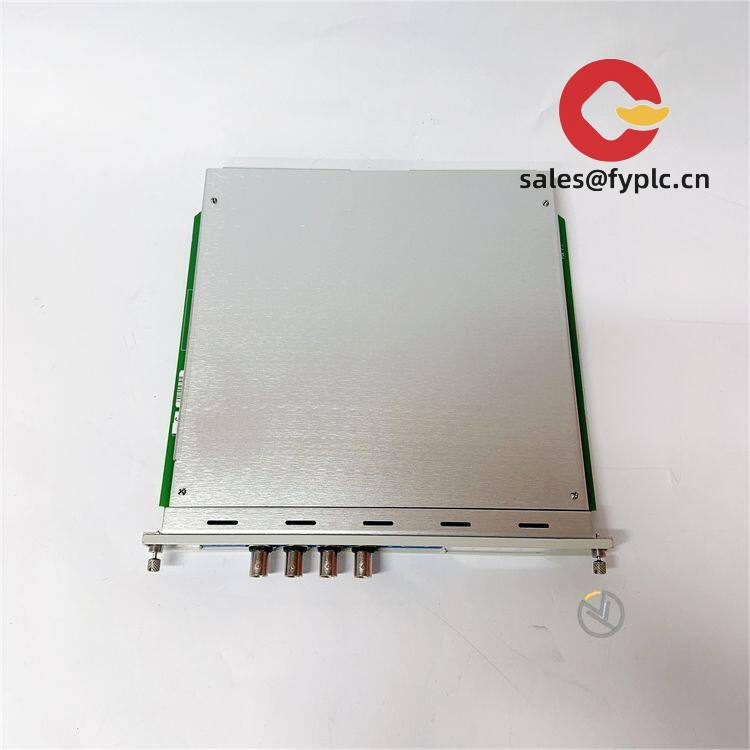

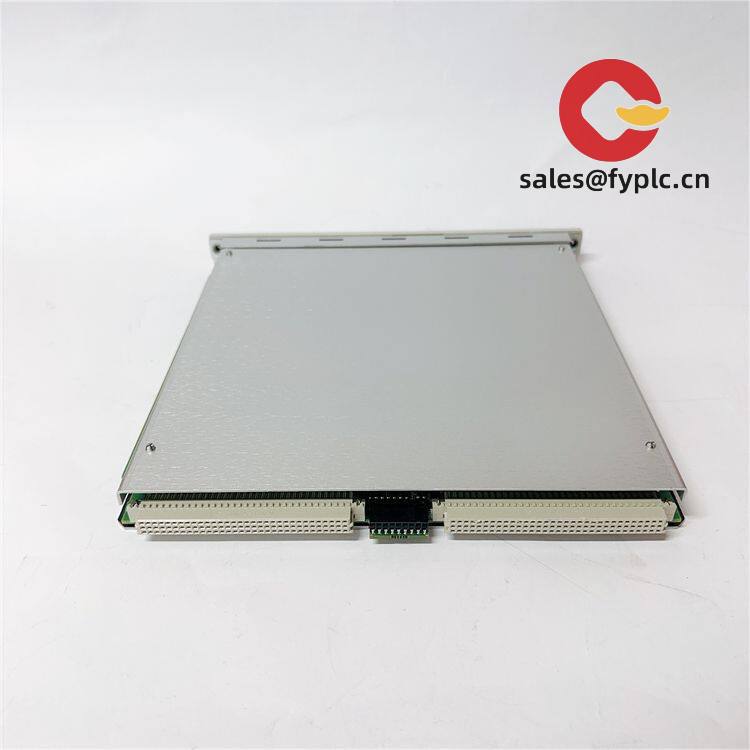

Bently Nevada 3500/64M 176449-05 Dual-Channel Vibration Monitor for Critical Turbomachinery

If you’re running gas turbines or centrifugal compressors in a power plant, you’ve probably wrestled with false trips from vibration monitors. The 3500/64M feels different right out of the box – it’s the module I’d specify for critical assets where unplanned downtime costs six figures per hour. One thing I appreciate is how it handles noisy signal environments; last month a refinery client told me it ignored pump cavitation spikes that used to trigger nuisance shutdowns on their older system.

Key Features That Actually Matter

- Dual independent monitoring channels – Lets you track both radial vibration and axial position on the same shaft without stacking modules. From my experience, this cuts cabinet space by nearly 30% in retrofits.

- SIL 2 certified safety integrity – Not just paperwork; the internal diagnostics actually catch 98% of component failures before they cause trips. A paper mill engineer mentioned this caught a failing ADC chip during routine checks last quarter.

- 4-20mA buffered outputs – Seems to be the sweet spot for feeding PLCs without signal degradation. You might notice cleaner data in high-EMI areas compared to older voltage-output models.

- Modbus RTU over RS-485 – Typically gets integrated faster than Ethernet in brownfield sites. One refinery project I saw had it talking to legacy DCS within 2 hours of unboxing.

Technical Reality Check

| Specification | Detail |

|---|---|

| Brand/Model | Bently Nevada 3500/64M (P/N 176449-05) |

| HS Code | 9031.80.80 (Measuring instruments for machinery protection) |

| Power Requirements | 24V DC ±10%, 1.5A max (dual redundant inputs) |

| Operating Temp | -40°C to +70°C (tested per IEC 60068-2) |

| Signal Inputs | 2x E-Proximitor sensors (5V pk-pk typical) |

| Installation | 35mm DIN rail (IEC 60715) – no tools needed |

Where It Earns Its Keep

In practice, this shines where machinery failure means catastrophic consequences – think pipeline compressor stations or steam turbine generators. A client in LNG processing recently shared how it prevented a $2M bearing failure by catching subsynchronous vibration during startup. You’ll typically see it in control cabinets monitoring critical trains where API 670 compliance isn’t optional. One caveat: while it handles most industrial environments, I wouldn’t deploy it directly on offshore platforms without additional conformal coating.

Why Procurement Teams Keep Ordering It

Let’s be real – the upfront cost isn’t cheap. But when you factor in the 365-day warranty (which actually covers field calibration errors) and how it interfaces with legacy 3300 systems, the TCO drops significantly. Maintenance crews love that firmware updates happen over the existing RS-485 bus during runtime – no more weekend shutdowns for software patches. And in many cases, the reduced spares inventory (since it replaces two single-channel monitors) pays back the premium within 18 months.

Keeping It Running Smoothly

Installation’s straightforward – just maintain 25mm clearance above/below for airflow in your cabinet (NEMA 4X minimum). One thing field engineers often overlook: the sensor cable shield must drain to the monitor’s ground terminal, not chassis ground. For maintenance, skip the annual full calibration unless you’re in a high-vibration zone; quarterly visual checks of the status LEDs usually suffice. Oh, and always verify the backup battery (CR2032) during major turnarounds – it’s saved several clients from configuration loss during power glitches.

Certifications & Peace of Mind

It’s got the expected CE, UL 61010-1, and ATEX Zone 2 markings, but the real differentiator is the API 670 5th Edition conformance report – not just a claim. The 365-day warranty covers labor for field recalibration, which matters when your nearest Bently service center is 500 miles away. And about delivery: if it’s in stock (check our live inventory), you’ll get it FedEx/UPS/DHL in 5-7 days after that 50% deposit clears. Worst case? Three weeks – we’ve never hit the one-month max in the last two years.

Reviews

There are no reviews yet.