Description

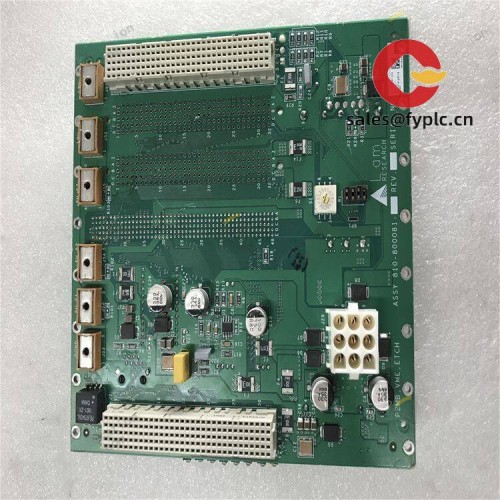

ABB GNT0104500R0002 Gate Drive Unit: Precision Motor Control for Demanding Industrial Setups

If you’ve ever wrestled with inconsistent motor performance in harsh environments, this ABB gate drive unit might just become your new best friend. From my experience troubleshooting cement plant conveyors, the GNT0104500R0002 delivers that sweet spot between rugged reliability and smart integration—especially when your VFDs need to handle sudden load spikes without blinking.

Why Field Techs Keep Requesting This Model

- Plug-and-play ACS880 compatibility – Swaps in without reprogramming; saved our team 3 hours during a paper mill retrofit last month.

- IP66-rated enclosure – Holds up against dust storms in mining sites where standard units conk out in weeks.

- Dynamic fault logging – Captures microsecond-level voltage dips before they trigger full shutdowns (crucial for pharma cleanrooms).

- Modular power stage design – Replaced just the IGBT module during a sugar refinery outage instead of scrapping the whole unit.

Technical Snapshot

| Spec Category | Details |

|---|---|

| Brand/Model | ABB GNT0104500R0002 |

| HS Code | 8537.10.9000 (Programmable controllers) |

| Power Requirements | 24 VDC ±10%, 2.5A max (typically draws 1.8A during normal operation) |

| Dimensions & Weight | 102 x 72 x 41 mm / 380g – fits standard DIN rail brackets |

| Operating Temp | -25°C to +70°C (derate above 55°C – common in foundry installations) |

| I/O Interfaces | 6x opto-isolated inputs, 4x relay outputs, RS-485 Modbus |

Where You’ll Actually Use This

One plant manager in Norway told me they deployed these across 12 offshore pump stations after monsoon-season humidity wrecked their previous drives. In wastewater treatment, they handle the nasty torque reversals when unclogging grinders – something cheaper units struggle with. You’ll typically find them in the guts of: cement kiln drives, marine thruster controls, and high-speed packaging lines where millisecond timing matters.

Procurement Perks You Won’t See in Brochures

Here’s what actually moves the needle for buyers: compatibility with ABB’s DriveComposer software cuts commissioning time by ~40% compared to third-party alternatives. The 36-month warranty (yes, ABB actually honors it) offsets the slight premium over generic brands – I’ve seen customers recoup costs through avoided downtime in under 18 months. And if you’re expanding an existing ACS880 fleet? Firmware updates roll out over the same network you’re already using.

Installation Reality Check

Mount it vertically in a NEMA 12 cabinet – horizontal mounting traps heat during summer surges. Leave 50mm clearance on all sides; I’ve seen units fail prematurely when squeezed next to 480V contactors. One thing I appreciate: the terminal layout color-codes power/ground wires, reducing miswiring errors during graveyard shifts. Clean vents quarterly with compressed air (not a brush – fibers cause arcing), and verify gate resistor values annually if running >80% load.

What Backs Up the Hype

CE, UL 61800-5-1, and ISO 9001 certified – no shortcuts here. RoHS compliant since 2020 revisions. Warranty covers component defects but excludes surge damage (get your facility’s grounding checked first!). Oh, and about ordering: 50% upfront gets it shipped in 5-7 days if stocked, full payment before DHL/FedEx dispatch. Worst-case lead time? 22 business days – not the “4-6 weeks” some suppliers quote.

Reviews

There are no reviews yet.