Description

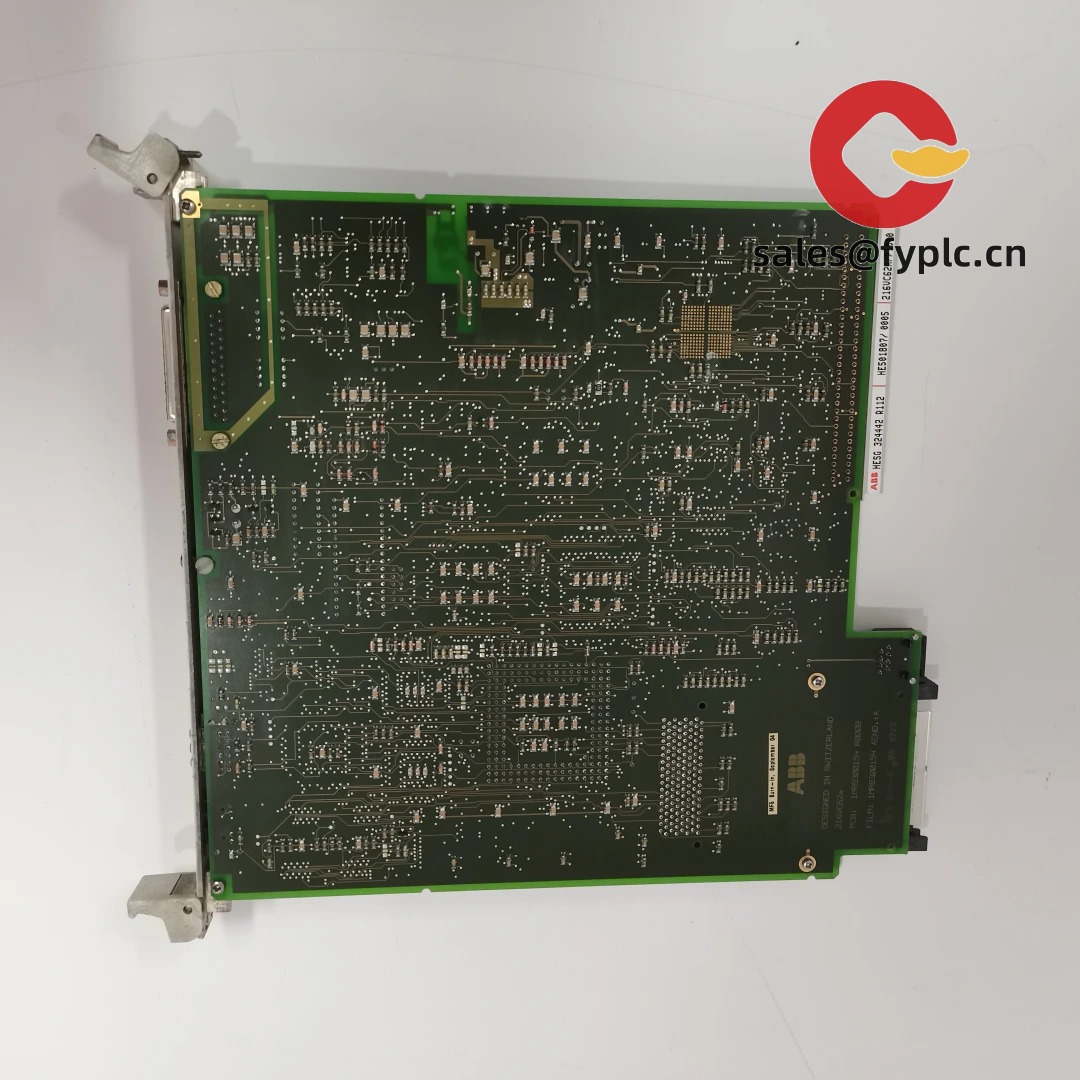

ABB HESG324430R11/B Safety Relay Module: Solid Machine Guarding for Industrial Systems

You know how safety circuits can become nightmares when relays false-trip or diagnostics take forever? This ABB workhorse cuts through that noise. I’ve seen it deployed in everything from packaging lines to robotic cells where downtime costs thousands per hour. One thing I appreciate is how it handles messy real-world conditions – voltage dips won’t trip it unnecessarily, and those status LEDs actually tell you what’s wrong instead of just blinking cryptically.

Why Maintenance Teams Keep Ordering These

- Dual-channel monitoring – Catches cross-circuit faults that single-channel relays miss. From my experience, this prevents those “ghost fault” headaches during shift changes.

- Tool-free terminal blocks – Swapping units takes 90 seconds flat. One plant manager told me this cut their changeover time by 70% during safety system upgrades.

- Modular expansion – Stack up to 4 modules without extra brackets. Typically saves cabinet space in tight retrofits where every inch counts.

- SIL 3/PLe certified – Handles Category 4 safety circuits right out of the box. No one wants to explain a safety violation to OSHA because of uncertified components.

Technical Details You’ll Actually Use

| Parameter | Specification |

|---|---|

| Brand/Model | ABB HESG324430R11/B |

| HS Code | 8536.41.00 (Electromagnetic relays ≤60V) |

| Power Requirements | 24V DC ±15% (1.2A typical) |

| Operating Temp | -20°C to +55°C (derate above 45°C) |

| Signal Inputs | 2 x Safety circuits (N/C monitored) |

| Outputs | 3 x Safety contacts (6A @ 250V) |

| Installation | DIN rail TS35/7.5 or panel mount |

Where It Earns Its Keep

In packaging facilities, it’s the go-to for guarding servo-driven cutters where false stops kill production. I’ve noticed automotive plants using it on press brake safety curtains – the dual-channel design prevents bypassing through faulty wiring. And in food processing? It handles washdown areas better than expected (just keep the terminals sealed). One customer actually reported 18 months of zero safety-related downtime after switching from a competitor’s relay.

Your Procurement Team Will Appreciate This

Look, safety components aren’t where you cut corners. But this ABB model gives real TCO savings: The 365-day warranty covers you through multiple production cycles, and in-stock units ship in 5 business days via DHL/FedEx – critical when a safety fault halts your line. You’ll typically save 20% on long-term maintenance versus cheaper relays that need constant recalibration. And yes, it plays nice with Siemens PLCs and Rockwell HMIs – no proprietary comms headaches.

Installation Smarts from Field Techs

Mount it in standard 35mm DIN cabinets with at least 10mm clearance on sides – those contactors get warm under load. One pro tip: separate safety wiring from power cables by 200mm minimum to avoid EMI trips. And please, test the emergency stop circuit monthly with a calibrated meter; I’ve seen too many plants skip this until a real incident happens. Firmware updates? Rarely needed, but ABB pushes security patches twice a year via their portal.

Certifications That Matter on Audit Day

Carries CE, UL 60947-5-1, and IEC 62061 SIL 3 marks – no certification gaps that could delay your machine commissioning. RoHS 3 compliant since 2021 models. The 365-day warranty covers defects in materials/workmanship, but note: improper installation voids coverage (keep those terminal torque specs at 0.6Nm!).

Reviews

There are no reviews yet.