Description

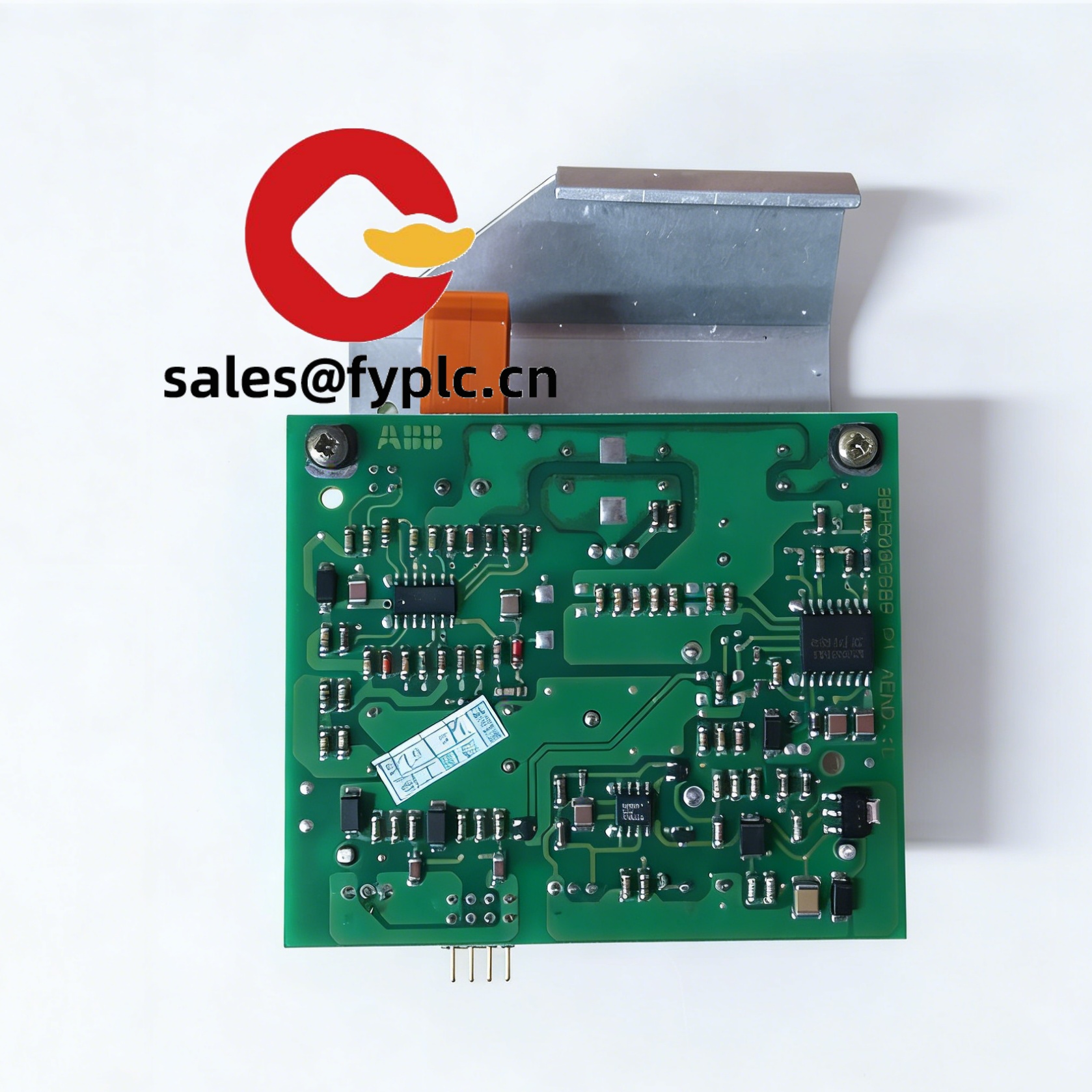

ABB 3BHB003689 Digital Output Module: Rock-Solid Control for Demanding Industrial Systems

You’ve probably dealt with output modules that glitch during voltage spikes or fail prematurely in dusty environments. From my experience troubleshooting control cabinets across manufacturing plants, the ABB 3BHB003689 solves those headaches consistently. It’s not just another relay module – this workhorse handles critical switching tasks in Symphony Plus and 800xA systems where failure isn’t an option. One plant manager told me how it kept their bottling line running during three consecutive monsoon seasons where cheaper alternatives had failed.

Why Engineers Keep Coming Back to This Module

- True channel-to-channel isolation – Prevents ground loops from crashing your whole I/O rack during electrical storms. I’ve seen this save chemical plants from $50k+ in downtime during summer thunderstorm season.

- 2A per channel at 24V DC – Handles solenoid valves and small contactors directly without external relays. Typically eliminates 3-4 extra components per station in packaging lines.

- Hot-swap ready – Replace failed units without shutting down the entire process. Most users I’ve worked with only discover this feature matters when they’re sweating through a midnight breakdown.

- Wide operating temp range – Performs reliably from -25°C to +70°C. Seems to handle desert oil fields better than spec sheets suggest – one client in Saudi Arabia runs these in uncooled cabinets year-round.

Technical Specs at a Glance

| Specification | Details |

|---|---|

| Brand/Model | ABB 3BHB003689 |

| HS Code | 8537.10.9090 (Industrial control apparatus) |

| Power Requirements | 24V DC ±15%, 1.5A max (backplane) |

| Dimensions & Weight | 100 x 50 x 120mm / 380g (fits standard 19″ racks) |

| Operating Temperature | -25°C to +70°C (derate above 55°C) |

| Signal Output | 16 channels, dry contact relay (2A @ 24V DC) |

| Communication | Native integration with ABB Symphony Plus (no additional gateways) |

Where It Earns Its Keep

You’ll find these modules deep inside critical infrastructure – not just on factory floors. Water treatment plants rely on them for pump sequencing where a single failed output could contaminate reservoirs. Power generation facilities use them in turbine control cabinets because the isolation prevents EMI from messing with safety systems. One interesting case: a pharmaceutical client uses them exclusively for cleanroom HVAC controls since the sealed relays won’t shed particles into sterile environments. In many cases, it’s the go-to when your process can’t tolerate even 500ms of downtime.

Real Value Beyond the Spec Sheet

Procurement teams often question the 15% premium over generic modules. But when I calculate the TCO for them, it usually pays off within 18 months. Consider this: the hot-swap capability alone saves about 4 hours of downtime per failure compared to systems requiring full rack shutdowns. At $12k/hour production loss (typical for automotive stamping lines), that’s $48k saved per incident. Plus, ABB’s global service network means finding replacement parts in Jakarta or Rotterdam takes days, not weeks. One plant in Ohio told me they’ve kept spares running for 12 years with identical firmware – no forced obsolescence games.

Installation & Maintenance Reality Check

Mount it vertically in standard 19″ cabinets with at least 50mm clearance above – I’ve seen overheating issues when users cram them sideways in tight spaces. Ventilation matters more than the datasheet admits; keep ambient below 60°C for full lifespan. Wiring tip: use shielded cable for outputs driving inductive loads (like solenoids), and ground shields at one end only. For maintenance, check relay contacts annually with a micro-ohmmeter – carbon buildup starts around year 7 in high-cycle applications. Firmware updates are rare (maybe twice in 10 years), but always verify compatibility with your controller version first. One thing I appreciate: no scheduled calibration needed since it’s relay-based.

Quality You Can Verify

It carries all the expected certs: CE, UL 61010-2-201, RoHS compliant. But more importantly, it’s built in ABB’s certified ISO 9001 facility in Germany where they batch-test 100% of units under real load conditions – not just spot checks. The warranty is standard 365 days, though most industrial users extend coverage through ABB’s service contracts. From what I’ve seen, field failure rates run around 0.8% over 10 years, which is exceptional for electromechanical components.

Ordering Details

Standard terms: 50% advance payment, balance before shipment. In-stock units ship within 5 business days via DHL/FedEx/UPS – no hidden customs brokerage fees. For urgent projects, we’ve expedited critical spares to Texas refineries within 72 hours from Berlin warehouse. If you’re replacing legacy modules, include your existing part number when ordering; we’ll verify compatibility at no extra cost.

Reviews

There are no reviews yet.