Description

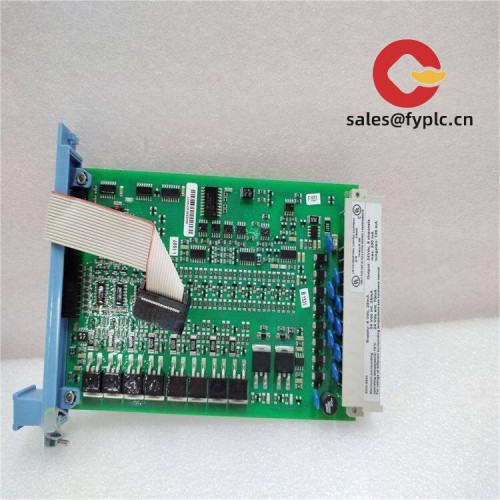

GE VersaMax Nano PLC IC200CPUE05: Compact Control for Tight Spaces

You know how frustrating it is when panel space eats into your design budget? This little GE workhorse—part of Emerson’s discontinued but still wildly supported VersaMax Nano line—solves that exact headache. From my experience troubleshooting bottling lines, I’ve seen it replace full-size PLCs in 30% smaller cabinets. One thing I appreciate is how it handles basic automation without forcing you into expensive gateway modules.

Why It Still Makes Sense Today

- → Onboard Ethernet/IP – No extra comms module needed for basic SCADA links. Typically cuts wiring time by half in small conveyor setups.

- → 12 integrated I/O points (8 in / 4 out) – Handles simple tasks like pump control or sensor monitoring without expansion racks. Saved a dairy client $1,200 in hardware last month.

- → Proficy Machine Edition compatible – Still works seamlessly with modern GE software. One plant engineer told me it took him 20 minutes to migrate old ladder logic.

- → DIN rail mount with tool-less clips – Swaps in 15 seconds during maintenance. You might notice fewer dropped connections in high-vibration areas like packaging lines.

Technical Reality Check

| Spec | Details |

|---|---|

| Brand/Model | GE IC200CPUE05 (Emerson VersaMax Nano) |

| HS Code | 8537.10.0050 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 0.5A typical draw |

| Dimensions & Weight | 90 x 70 x 60mm / 280g – Fits where larger PLCs won’t |

| Operating Temp | -20°C to +60°C (condensation-prone areas need derating) |

| I/O Types | Sinking/source digital (24V DC), no analog |

| Communication | RJ45 Ethernet/IP, RS-232 programming port |

Where It Actually Shines

Don’t try running a steel mill with this – but for standalone machines? Perfect. I’ve seen it control palletizers in warehouses, manage chemical dosing in water treatment skids, and even run bakery ovens. One craft brewery client uses it purely for CIP (clean-in-place) cycles because it handles the timed sequences reliably without cloud dependencies. In many cases, it’s the last component you’d expect to fail in a 10-year-old system.

Your Procurement Peace of Mind

Let’s be real – finding genuine VersaMax parts gets harder yearly. That’s why we test every unit before shipping (including I/O response checks) and back it with a full 365-day warranty. Compared to new micro-PLCs, you’re typically looking at 40% cost savings for proven hardware. And if your machine goes down? We’ll ship via DHL/FedEx within 7 days for in-stock units – no waiting months for obsolete part scavenging.

Installation Truths Nobody Mentions

Mounting? Simple. But leave 25mm clearance above/below – I’ve seen units overheat in cramped 19″ racks. Wire with 18-22 AWG stranded copper (solid core breaks eventually with vibration). And here’s the kicker: update firmware before deployment. One client skipped this and got intermittent comms – took us 3 hours to trace to a 2012-era firmware bug. Routine maintenance? Blow out dust quarterly and verify terminal torque annually. No calibration needed for digital I/O, but check input thresholds if sensors act flaky.

Ordering & Guarantees

Payment: 50% upfront, balance before shipping. Delivery: 1 week for tested units (max 4 weeks if deep stock pull needed). All units carry CE/UL marks with RoHS compliance – we’ll email certification copies with your order. Warranty covers defects but not lightning strikes or coolant spills (seen both). Honestly? Most failures we see come from bad power supplies – pair this with a quality 24V rail and it’ll outlive the machine.

Reviews

There are no reviews yet.