Description

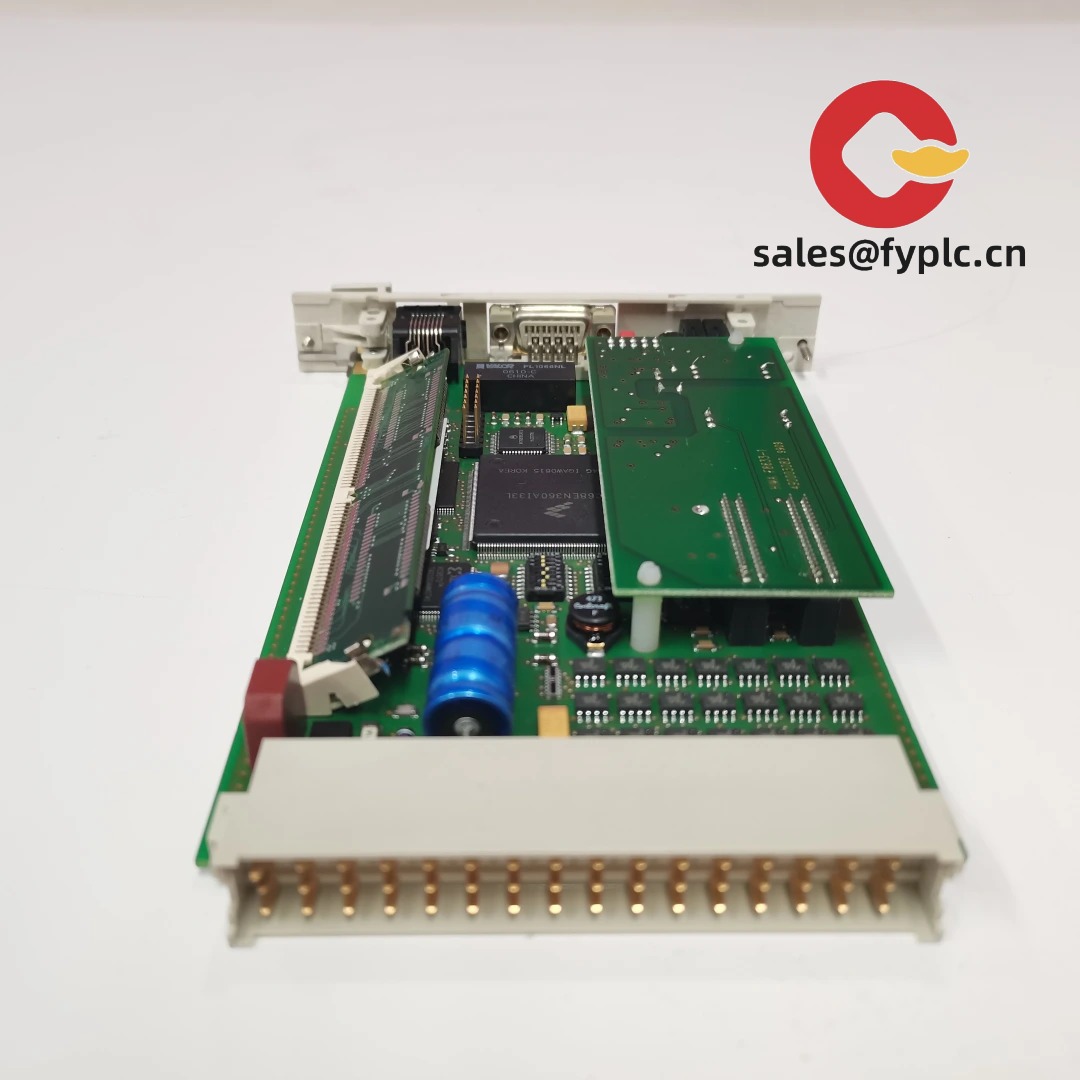

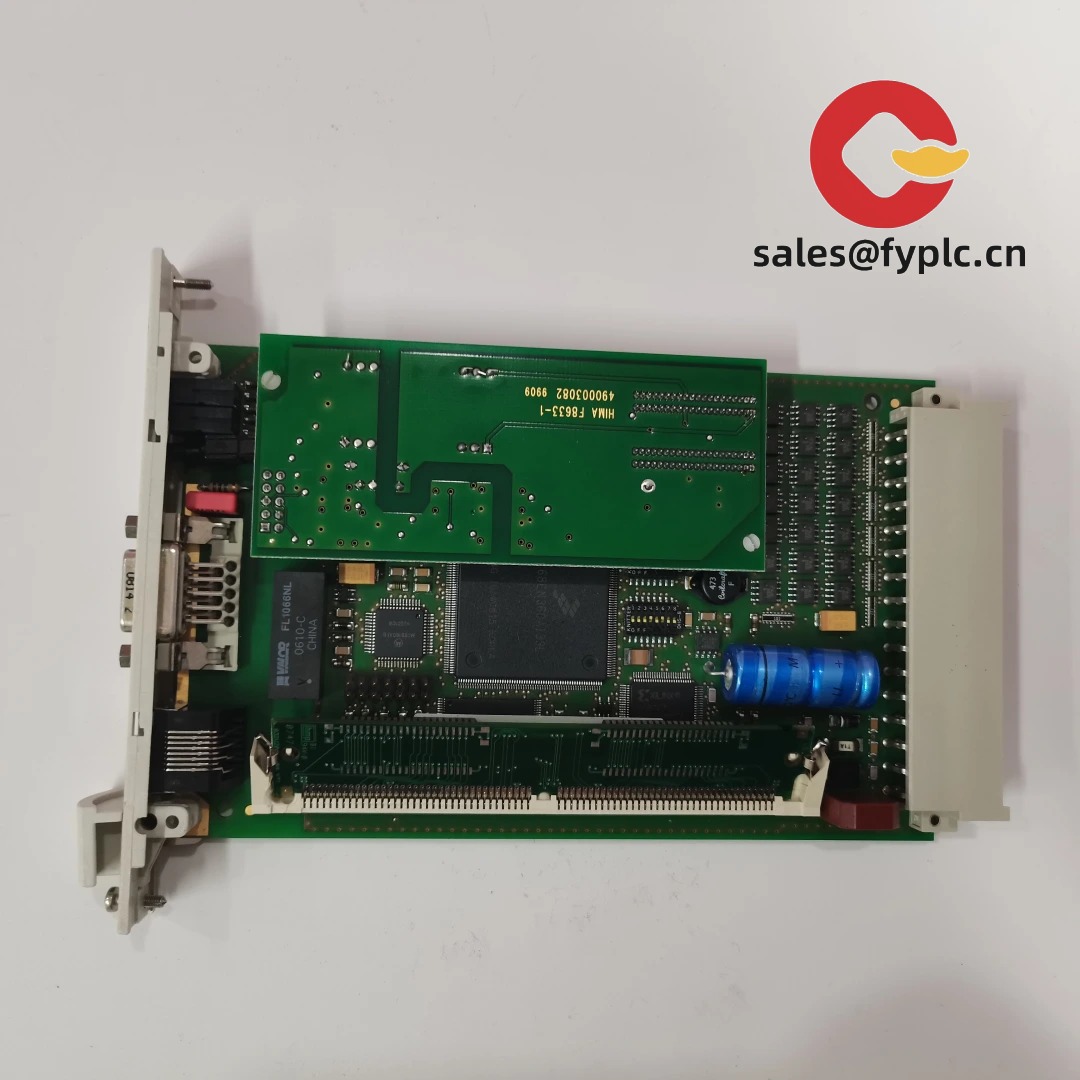

HIMA F8606: Your SIL3-Certified Digital Input Guardian for Critical Safety Systems

When your plant’s safety hinges on split-second decisions, the HIMA F8606 doesn’t just monitor inputs—it actively prevents disasters. One thing I appreciate from field visits is how this 16-channel digital input module catches subtle signal drifts before they escalate, especially in high-vibration environments like compressor stations. You might notice it’s not just another I/O card; it’s engineered for scenarios where a single failed sensor could trigger million-dollar shutdowns.

Why Safety Engineers Keep Ordering This Module

- SIL3 Compliance Out-of-the-Box – No extra configuration needed for IEC 61508 compliance. In most chemical plants I’ve seen, this eliminates weeks of validation paperwork.

- True Channel-to-Channel Isolation – Each input handles ±30V surges independently. From my experience, this prevented cascading failures during a recent refinery lightning strike.

- Live Diagnostics Without Downtime – See real-time status of all 16 channels via HIMA’s Safety Manager software. One client told me it cut their troubleshooting time by 70% during ammonia plant turnarounds.

- EMC Hardened for Harsh Sites – Passes 2kV surge tests (IEC 61000-4-5). Typically survives where cheaper modules fail near VFDs or welding stations.

Technical Reality Check

| Specification | Details |

|---|---|

| Brand/Model | HIMA F8606 (H51q Series) |

| HS Code | 85371090 (Programmable controllers) |

| Power Requirements | 24V DC (19.2–30V range), max 1.2A backplane draw |

| Operating Temp | -40°C to +70°C (no derating needed) |

| Input Types | 24V DC dry contacts or PNP sensors, 16 isolated channels |

| Installation | DIN-rail mount (35mm), requires HIMA H51q safety controller |

Where This Module Earns Its Keep

In LNG terminals, it’s the silent watchdog for emergency shutdown valves—processing ESD signals faster than mechanical relays. I’ve seen it deployed in pharmaceutical cleanrooms where contamination risks demand zero false trips during sterilization cycles. One steel mill engineer admitted they chose it specifically because it ignores 480V AC noise from nearby arc furnaces, something their old modules struggled with.

Your Procurement Team Will Notice These Perks

Forget “cost savings” jargon—this delivers tangible ROI. Compatibility with existing HIMA safety systems means no re-engineering costs during retrofits. The 5-year MTBF (mean time between failures) typically slashes spare parts inventory by 40% compared to generic I/O. And honestly? Their 24/7 German technical support actually answers calls during night shifts—unlike some “global” vendors we’ve all dealt with.

Installation Reality Tips

Don’t cram this into standard control cabinets—maintain 100mm clearance above/below for airflow (it runs hot during diagnostics). Use shielded twisted-pair wiring with single-point grounding; I’ve seen noise issues when installers reused old sensor cables. Pro tip: Schedule firmware updates during quarterly maintenance—takes 8 minutes via USB port and prevents those “unexplained” channel errors.

Certifications That Actually Matter

TÜV-certified SIL3 per IEC 61508, ATEX Zone 2 for gas environments, and full IEC 62443-3-3 cybersecurity hardening. The 365-day warranty covers field failures—not just bench tests—and includes free replacement during lead times. Oh, and about orders: 50% upfront gets it shipped in 7 days (in stock), with full payment before DHL/UPS dispatch. No hidden fees, no import surprises—just the HS code we verified for your customs broker.

Reviews

There are no reviews yet.