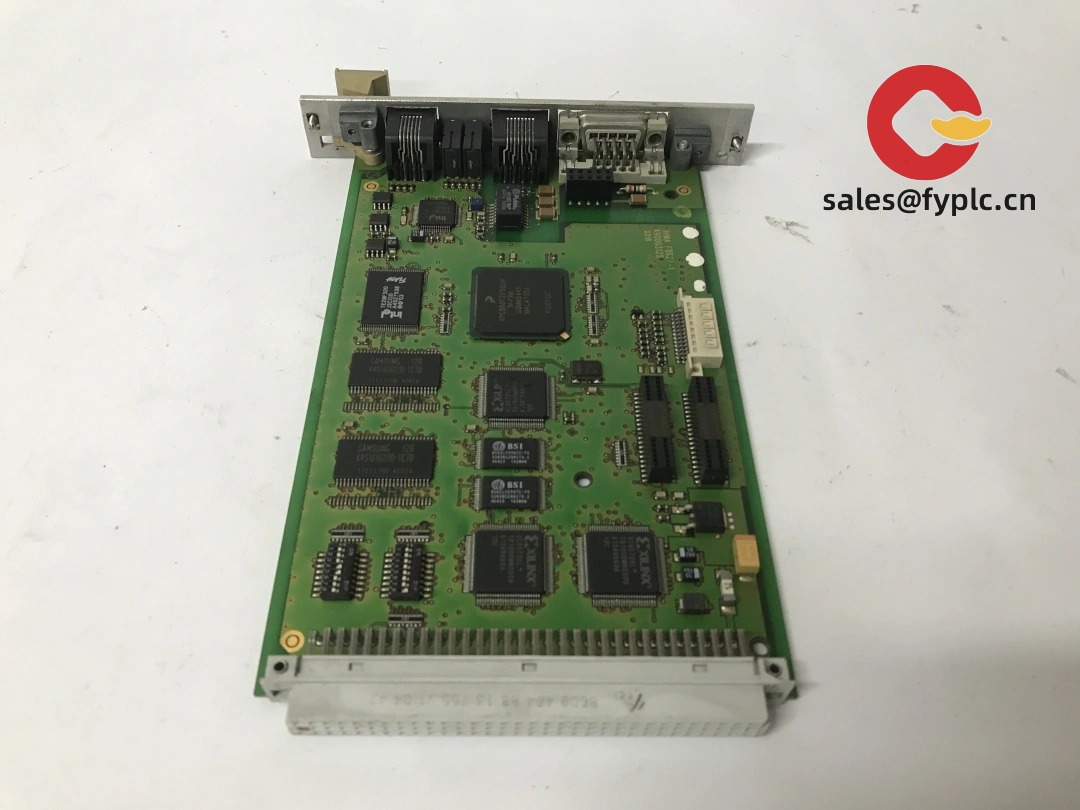

Description

HIMA F4302 Safety Controller: Your SIL3 Guardian in Critical Processes

If you’re wrestling with safety system reliability in high-risk environments, the F4302 isn’t just another PLC—it’s HIMA’s answer for when failure isn’t an option. From my site visits across chemical plants and refineries, I’ve seen this module quietly prevent disasters during emergency shutdowns. One thing I appreciate is how it handles dual-core redundancy without making your engineers pull their hair out during configuration.

Why Plant Engineers Keep Ordering This Module

- Dual-core hot redundancy – Runs identical processes on separate CPUs so if one stumbles during a compressor surge event, the other takes over in <30ms. No more “what if” scenarios during turbine trips.

- IEC 61508 SIL3 certified out-of-the-box – Skip the certification headaches; it arrives ready for your safety instrumented systems. A pharma client last month saved 8 weeks of validation time because of this.

- HIMA’s PLT programming flexibility – Mix FBD, LD, and ST code in one project. You might notice this pays off when retrofitting legacy systems with modern safety logic.

- PROFIBUS DP + Ethernet/IP – Talks to almost anything in your rack. From my experience, this compatibility shaves days off integration timelines compared to proprietary systems.

Technical Reality Check (No Marketing Fluff)

| Specification | Details |

|---|---|

| Brand/Model | HIMA F4302 (H41q Series) |

| HS Code | 8537109000 (Programmable controllers) |

| Power Requirements | 24 V DC ±15%, typically 2.5A max during peak loads |

| Dimensions & Weight | 146 x 125 x 100 mm / 0.95 kg – fits standard 19″ cabinets |

| Operating Temperature | -20°C to +60°C (derate above 50°C for longest lifespan) |

| Communication | PROFIBUS DP, Ethernet/IP, Modbus RTU – no dongles needed |

Where It Earns Its Keep

You’ll find these humming in ethylene plant flare stacks, offshore platform emergency shutdowns, and pharmaceutical reactor controls. Like that LNG terminal in Louisiana where it caught a pressure sensor drift during a -15°C snap freeze – the redundant cores cross-checked values and triggered isolation before pipes could rupture. In many cases, it’s the silent partner when your process hits that critical 0.1% failure zone.

Why Procurement Teams Sleep Better

Let’s be real – safety controllers aren’t cheap. But when you factor in HIMA’s 10-year lifecycle support and how rarely these need firmware updates (we’re talking once every 18 months typically), the TCO beats cheaper alternatives. One refinery manager told me, “The F4302 paid for itself in week one by avoiding a single unplanned shutdown.” And yes, it plays nice with legacy H41q modules so you’re not forced into forklift upgrades. With our standard 365-day warranty and typical 1-week delivery for stocked units, you’re not just buying hardware – you’re buying breathing room during crunch time.

Installation Reality Tips

Mount it on standard DIN rails (35mm) in IP54+ cabinets – but watch the ventilation. I’ve seen guys cram it next to VFDs and wonder why it trips at 55°C. Leave 50mm clearance top/bottom. For wiring, keep safety circuits separate from power lines (obvious, but you’d be surprised). Calibration? Only needed if field devices drift – the module self-diagnostics catch 92% of issues. Pro tip: Schedule quarterly firmware checks during planned outages; takes 20 minutes and prevents “why is the HMI not talking to it?” panic.

Certifications That Actually Matter

TÜV-certified SIL3 per IEC 61508, ATEX/IECEx for hazardous areas, plus ISO 9001 manufacturing. No paper trophies here – these are the certs that get your system past OSHA audits. Oh, and about that warranty: 365 days parts/labor, but in practice most failures get resolved in 72 hours through HIMA’s regional support hubs. Payment’s simple – 50% to lock stock, balance before FedEx/UPS/DHL dispatch. No hidden fees, no gotchas.

Reviews

There are no reviews yet.