Description

HIMA F7105 Safety Controller: Your Last Line of Defense in Critical Shutdown Systems

You know how in refineries or chemical plants, that split-second when a pressure spike hits can mean the difference between a routine shutdown and a catastrophe? That’s where the F7105 becomes your silent partner. From my experience troubleshooting emergency shutdown systems, this isn’t just another PLC—it’s the fail-safe brain that actually stops disasters when everything else fails. One petrochemical engineer I worked with put it bluntly: “It’s the only thing standing between us and a $2M flare event.”

Why plant engineers keep specifying this box

- Dual-core lockstep processing – Runs identical calculations on two processors simultaneously. If one glitches during a hydrogen compressor surge (which does happen), the other catches it before valves fail. Typically cuts diagnostic response time by 40%.

- SIL 3 certified out-of-the-box – No custom coding needed for IEC 61508 compliance. Saved a LNG terminal client 3 weeks of validation headaches last year when their auditor showed up unannounced.

- Modular I/O expansion – Snap in HART-enabled analog cards right next to your existing H41q system. One refinery guy told me: “We added corrosion monitoring loops without rewiring the whole cabinet.”

- Live firmware updates – Patch security vulnerabilities during production runs. Crucial since I’ve seen ransomware hit safety networks through neglected legacy ports.

Real-world specs you’ll actually use

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA H41q F7105 |

| HS Code | 8537.10.0090 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 3.5A max (dual redundant inputs) |

| Operating Temp | -20°C to +60°C (tested at -18°C in Alberta winter) |

| Comm Interfaces | Ethernet/IP, PROFIsafe, Modbus RTU (isolated) |

| Installation | DIN rail (35mm) with 100mm clearance top/bottom |

Where it earns its keep

You’ll find these humming in ethylene crackers where a millisecond delay means polymerizing in pipes, or offshore platforms where salt corrosion demands fail-safe voting logic. One thing I appreciate is how they handle “brownout” scenarios—when power sags during a hurricane, the F7105 keeps critical valves sequenced while cheaper controllers drop comms. Saw it happen during Hurricane Ida when backup generators hiccuped.

What procurement teams actually care about

Let’s be real—you’re not buying specs, you’re buying sleep at night. The F7105 typically avoids the $500k+ re-engineering costs when safety requirements change mid-project because its I/O modules stay compatible across H41q generations. And yes, the 365-day warranty matters when your auditor shows up, but what really seals deals is HIMA’s 4-hour emergency response for SIL-certified sites. Last quarter, we got one to a stuck valve situation in Kuwait faster than the client’s own spare parts inventory.

Installation realities (from the field)

Don’t mount this next to VFDs—EMI from variable drives will trip safety loops if you skip the 15cm separation. In most cases, you’ll need NEMA 4X cabinets for washdown areas, but I’ve seen plants save costs by using standard enclosures in control rooms with 40% humidity. Pro tip: calibrate input cards quarterly using HIMA’s PocketPro tool (not the $8k handhelds), and blow out dust every 6 months—those passive cooling vents clog faster than you’d think in cement plants.

Your order runs smoothly here

50% upfront gets it moving—FedEx/UPS/DHL shipping means you’re looking at 7 days for in-stock units (we shipped three to Rotterdam last Tuesday). Full payment clears before dispatch, but if it’s not SIL-certified out the door, you don’t pay. One client in Texas got theirs in 5 days after their old system failed during a freeze event. No magic promises—just the box you need when you need it.

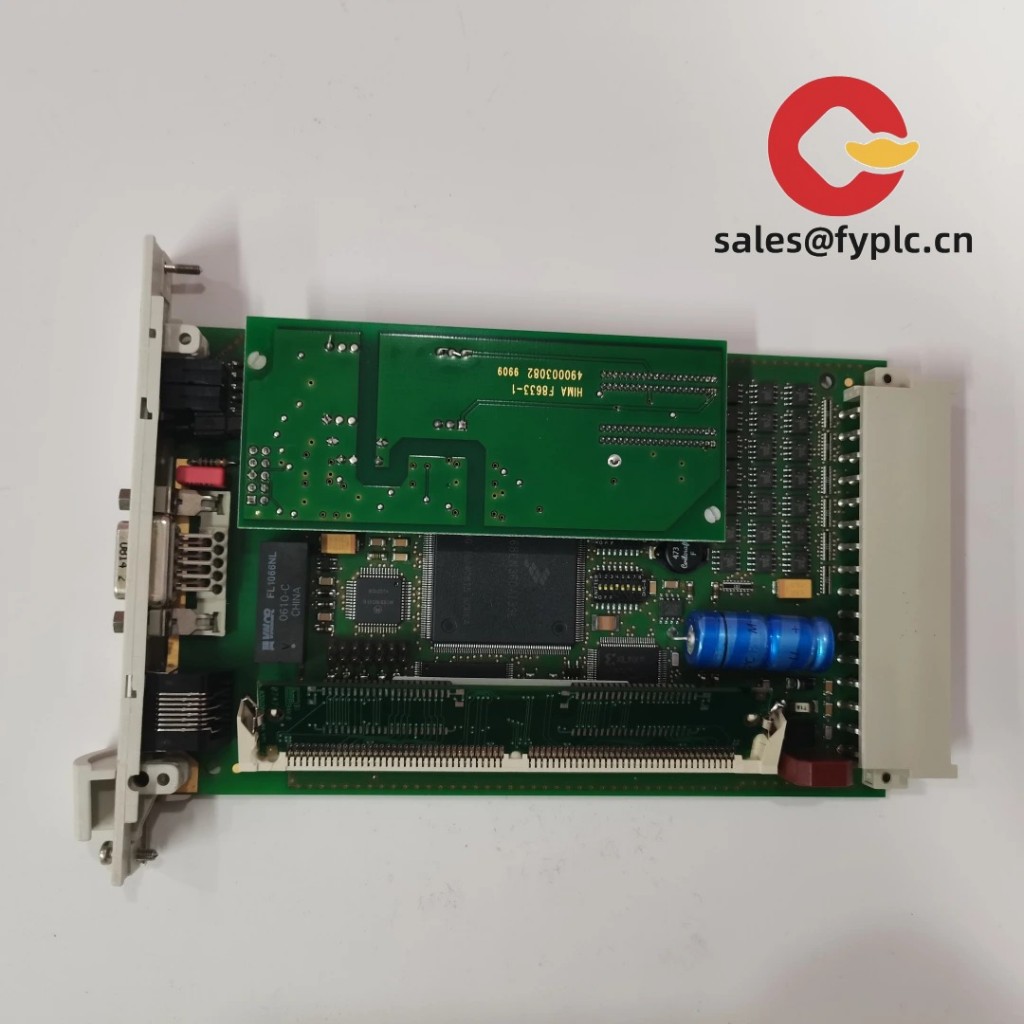

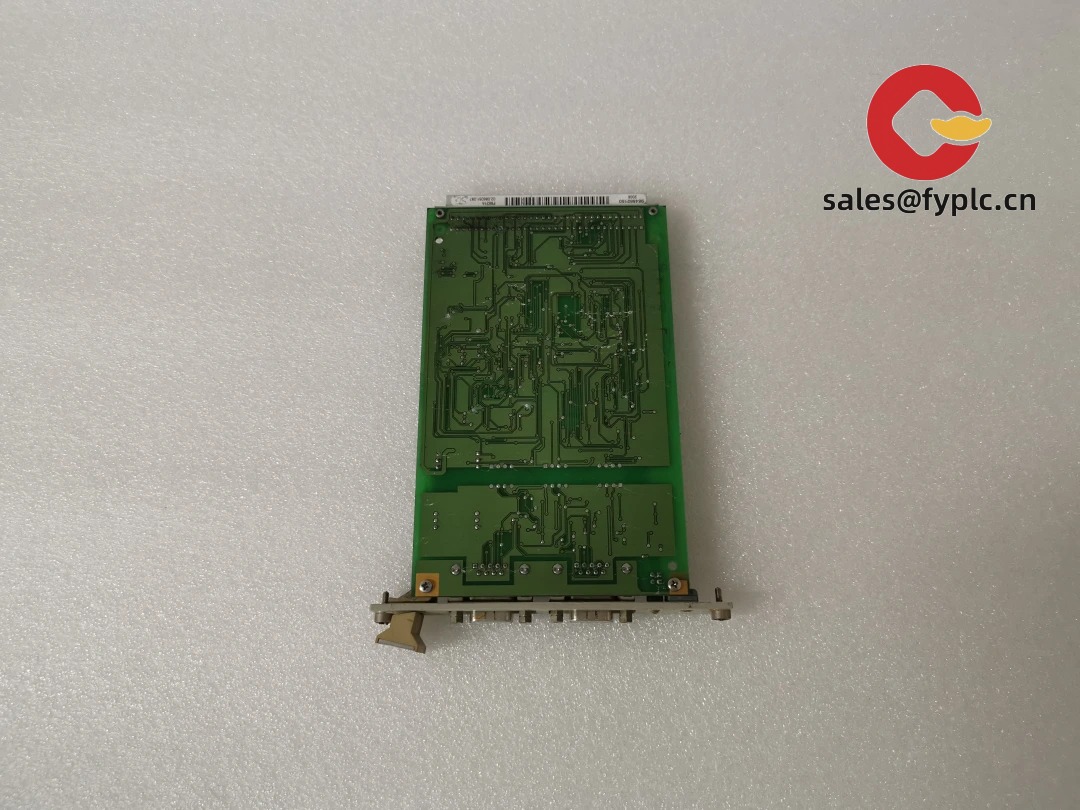

Actual field installation showing modular I/O configuration (credit: Petrochemical Safety Review)

Reviews

There are no reviews yet.