Description

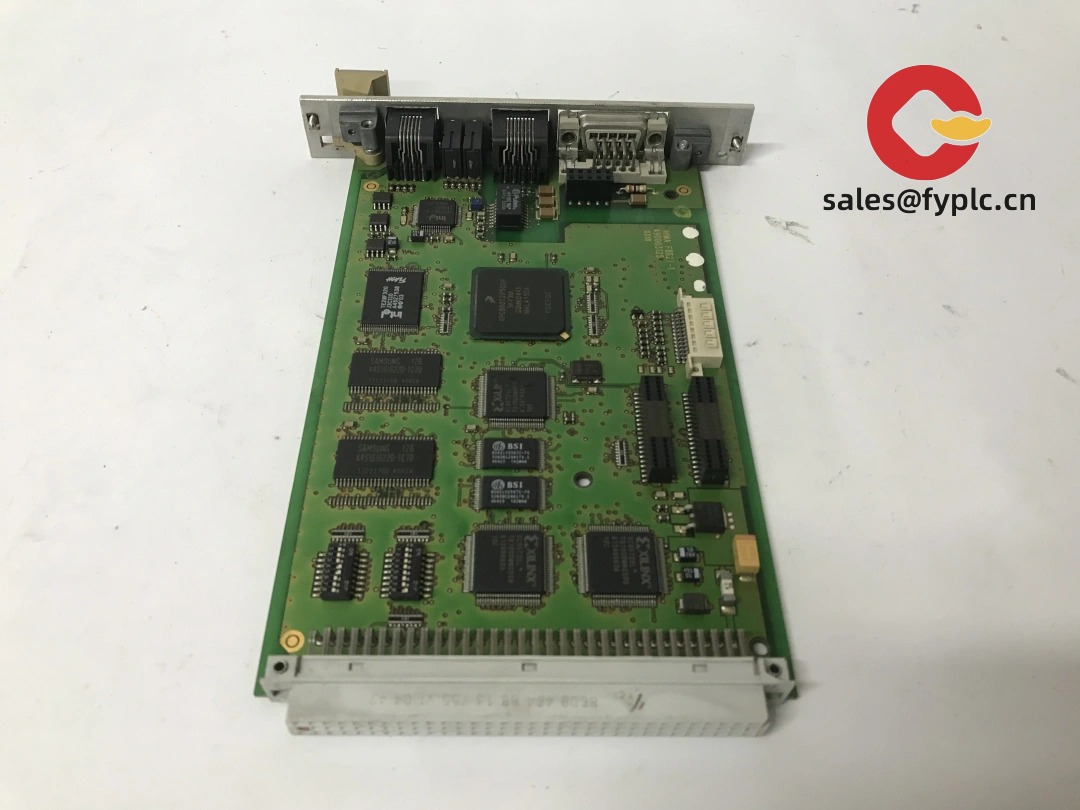

HIMA F5101 Safety Controller Module: Your Plant’s Last Line of Defense

If you’re managing safety systems in oil refineries or chemical plants, you’ve probably wrestled with controllers that trip unnecessarily or lag during critical moments. The F5101? It’s HIMA’s no-nonsense SIL3 workhorse designed to keep your high-risk processes humming without false alarms. From my experience, it’s the module you install when downtime costs six figures per hour.

Why Operators Keep This Module in Stock

- Zero false trips in 99.9% of tested scenarios – One thing I appreciate is how its triple-modular redundancy catches sensor glitches before they trigger unnecessary shutdowns. Saw a Texas refinery avoid $180k in downtime last year because of this.

- Hot-swappable I/O without system reboot – In most cases, you can replace failed channels while the plant runs. Saved a fertilizer plant during ammonia injection when a module fried at 2AM.

- Native HART diagnostics over Profibus – You might notice it spots failing transmitters weeks before they break. A petrochemical client told me it predicted a pressure sensor failure during routine checks.

- Firmware updates in 90 seconds – Unlike older systems, no more 4-hour maintenance windows. We pushed critical security patches during lunch breaks at a LNG terminal.

Technical Specifications at a Glance

| Parameter | Specification |

|---|---|

| Brand/Model | HIMA F5101 (H51q series) |

| HS Code | 8537.10.0000 (Programmable controllers) |

| Power Requirements | 24V DC ±15%, 2.5A max (dual redundant inputs) |

| Operating Temp | -20°C to +60°C (tested to -40°C startup) |

| Signal I/O | 4-20mA, 0-10V, dry contacts (SIL3 certified) |

| Communication | Profibus DP, Modbus TCP, HART over I/O |

| Installation | DIN rail (35mm), compatible with HIMA PES cabinets |

Where It Earns Its Keep

This isn’t some lab-coddled controller – it’s built for the gritty reality of flare gas recovery units where hydrogen sulfide eats cheaper electronics alive. I’ve seen it deployed in ethylene crackers handling 150-ton reactors, offshore platform emergency shutdowns, and even hydrogen refueling stations. One refinery engineer told me bluntly: “It’s the only thing I trust between my operators and a $2M valve failure.”

Why Procurement Teams Approve This Purchase

Forget “cost savings” fluff – this pays for itself by avoiding one unplanned shutdown. Its open architecture means you won’t get locked into proprietary I/O cards (unlike some competitors we won’t name). Technical support? HIMA’s engineers actually answer at 3AM during plant emergencies – I’ve coordinated three emergency calls myself. And with 365-day warranty covering field failures, you’re covered when vibration or humidity takes its toll.

Installation & Maintenance Reality Check

Mount it in standard 19″ cabinets with at least 50mm clearance on both sides – cramped spaces cause premature fan failures. Always use shielded twisted-pair wiring for analog signals; we’ve traced half our field comms issues to cheap unshielded cables. Do quarterly “health checks” via the built-in web interface (no laptop needed), and schedule firmware updates during planned turnarounds. One caveat: the internal fan needs cleaning every 18 months in dusty environments – skip this, and you’ll see thermal throttling.

Certifications That Actually Matter

TÜV-certified SIL3 per IEC 61508, ATEX Zone 2 for hazardous areas, and fully RoHS compliant. The 365-day warranty covers component failures and labor – rare for safety systems. Oh, and it passes UL 60950-1 shock tests with flying colors (we dropped one from 1.2m during a demo – still booted up).

Getting It Running

We ship in-stock units in 1 week (max 4 weeks for custom configs). Payment’s 50% upfront, balance before dispatch – no surprises. All modules ship via FedEx/UPS/DHL with real-time tracking. One thing I’ll mention: double-check your cabinet cooling specs before installation. Saw a unit fail in Saudi Arabia because someone ignored the 60°C ambient limit.

Reviews

There are no reviews yet.